Flux de traitement détaillé du granulateur plastique

Our company produces high-quality plastic recycling granulator. Our machines are mainly used for recycling and granulation of waste plastic. Our plastic recycling machines are becoming more and more important in the current situation of increasingly serious plastic pollution. Next, Shuliy Machinery will introduce the work process of our granulateur plastique for PP\PE waste plastic.

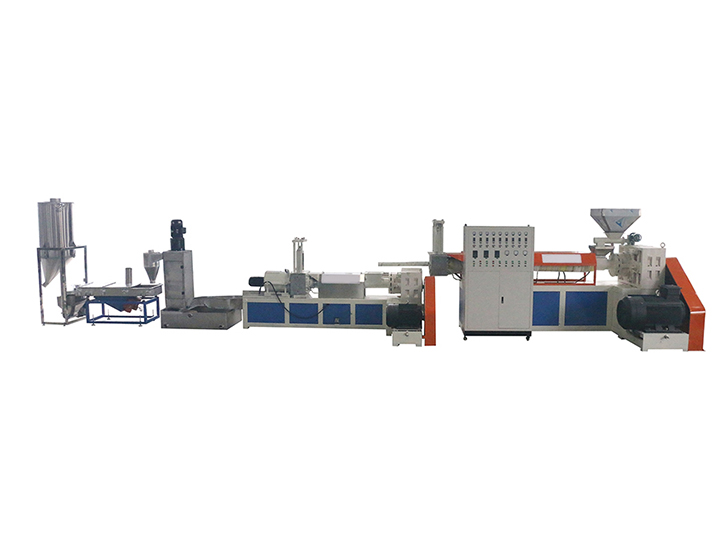

Working process of PP\PE waste plastic granulator:

First, waste PP\PE plastic is sent to the plastic cutting machine through the conveyor for crushing. Then the broken waste material enters the pool for cleaning (user can prepare the pool themselves), which is mainly to clean the impurities.

Second, cleaned plastic is dried by a dehydrator. Then dried plastic enters the rolling conveyor(This process can spread the plastic evenly to ensure that the plastic particles produced are relatively uniform). Finally, plastic from the conveyor enters the plastic pelletizing extruder through a feeder.

Plastic granulating extruder mainly heated and dissolved plastic, converts plastic from solid to liquid, and then pulls plastic into filament. During the operation of the plastic pelletizing extruder, the exhaust filter is configured to avoid environmental pollution. Filamentous plastic needs to be cooled in the pool. The cooled filamentous plastic is cut into pellets by a plastic cutter. That’s all the plastic processing process. Storage boxes, bagging machines, and other related equipment can be configured if the customer required.

Advantages of plastic granulator production line:

1. The plastic granulator adopts the latest technology, the latest design, which has a beautiful appearance and is convenient to use.

2. The plastic granulator has complete supporting facilities and can be automatically produced continuously(from raw material crushing, pulls plastic into filament to pellets cutting)

3. The full set of plastic granulators has the advantages of small footprint, low power consumption, high-quality finished products, wide application range.

4. Both the screw and the discharge port are made of high-strength carbon structure lead steel, which is durable and not easily deformed

The production capacity of our plastic granulator is 200KG / H-3000KG / H, which has a high production efficiency. In addition to plastic granulators, we also have a variety of plastic recycling machines, such as the recycling machine can process waste plastic into plastic pipes. If you have an interest in our machines, please leave a message and contact us.