Sayansi ya Wiani: Jinsi Tanki la Kutenganisha Kupitia Kupiga na Kuzama linavyofanya kazi

How do you separate PET flakes from bottle caps (PE) and rings (PP) automatically? The answer lies in the Sink-float separation tank, a masterclass in applying basic physics to industrial challenges.

The principle is density separation. PET has a density of ~1.38g/cm³, causing it to sink in water. Conversely, PP and PE have densities less than 1.0g/cm³, allowing them to float.

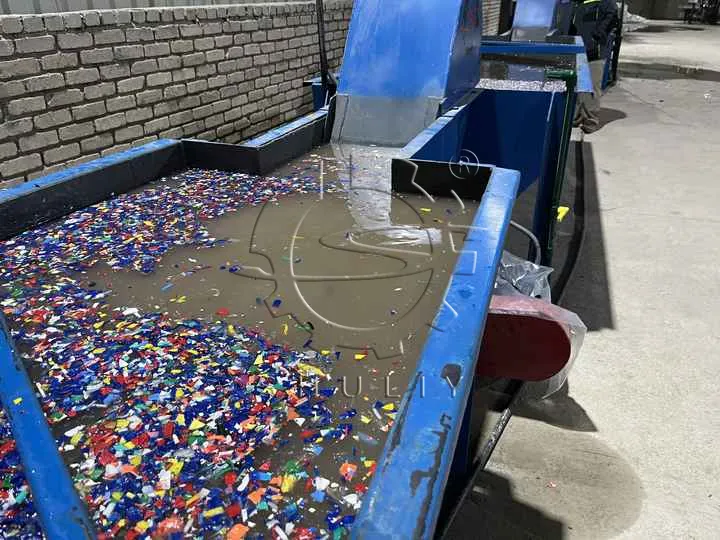

In our high-capacity PET bottle washing line, the flakes are agitated in the tank. The “sinkers” (pure PET) are collected by a screw conveyor at the bottom, while the “floaters” (labels and caps) are skimmed off the surface. To achieve the highest PET flake purity, we recommend a multi-stage setup. This ensures that even the smallest fragments of floating contaminants are removed, leaving you with a final product that meets the strictest international requirements.