Metal lastik parçalama için plastik parçalama makinesi

Metal lastik parçalama için plastik parçalama makinesi

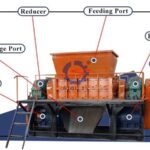

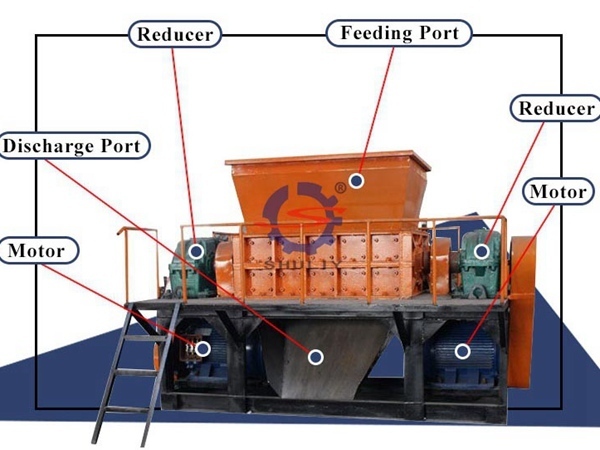

Bu plastik parçalama makinesi esas olarak, ham maddeyi kırmak için iki nispeten dönen kesici arasında kesme ve yırtma ilkesini kullanır. Plastik parçalayıcı, "çift motor + çift gezegen redüktörü" benimser, bu da güçlü bir güç ve çalışma sırasında yüksek stabilite sağlar. Genellikle atık bertarafı, atık kaynak geri dönüşümü ve atık yakma ön işleme gibi çevre koruma alanlarında kullanılır.

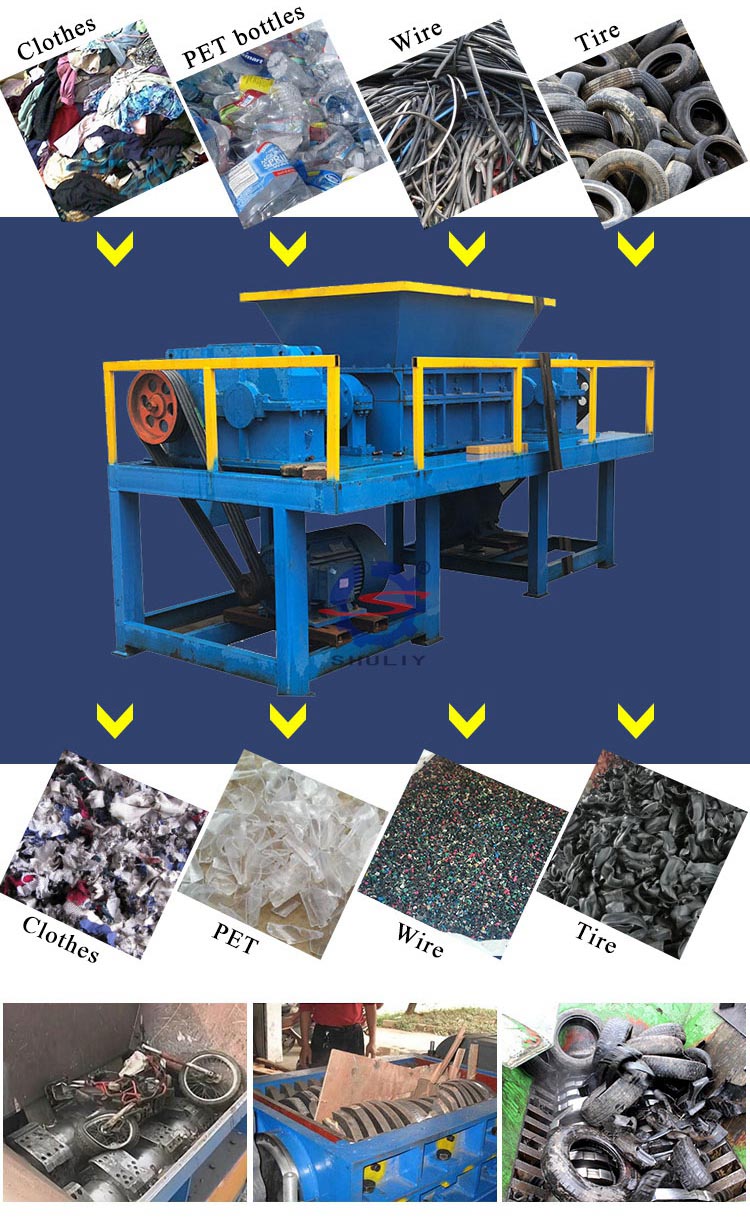

Plastik parçalama makinesi genel olarak plastik, kauçuk, lif, kağıt, ahşap, elektrik bileşenleri, kablolar gibi sert malzemeleri parçalamak için kullanılabilir. Örneğin, PET plastik şişeler, karton, devre kartları, ahşap, plastik variller ve kullanılmış lastikler. Hammaddeyi toz haline getirmek zor olduğu sürece, bu makineye girdikten sonra granül haline gelecekler.

Çift şaft kırıcı videosu

Plastik parçalama makinesinin özelliği

- Plastik parçalama makinesi, büyük blokları, sepetleri, boruları, levhaları, ahşabı, lastikleri, kullanılmış metal varilleri ve sıradan parçalama makineleriyle parçalanması zor olan büyük film rulolarını ezebilir.

- Birleşik çerçeveye sahip, ekstra kalın levha hassas işleme, büyük açılı bir kolon ile güçlü bir döner mil ve büyük çaplı katı bir huni ile donatılmıştır, böylece büyük şekilli ham maddeleri içine koyabilirsiniz.

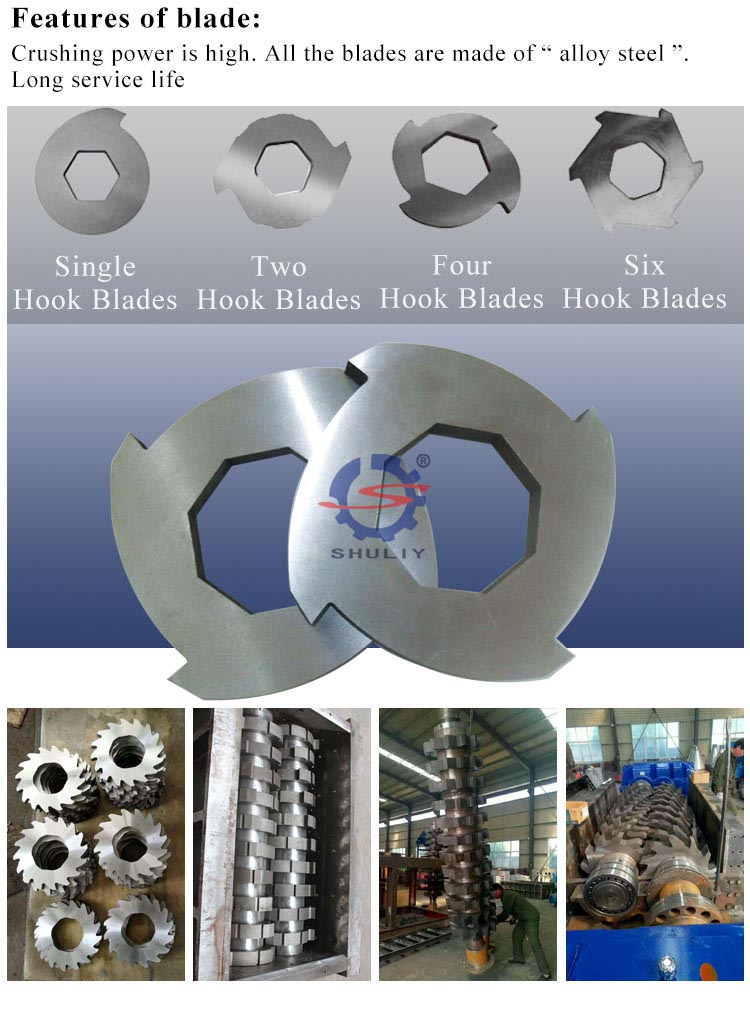

- Lastik Parçalama Makinesi, kalınlık, şekil, düzenleme sırası vb. açısından benzersiz bir döner bıçağa sahiptir; güçlü kesme kuvveti ve keskin kenarı ile atık malzemeleri yüksek verimlilikle ezme yeteneğine sahiptir.

- Plastik parçalayıcı, düşük hızda, düşük gürültü ile ve daha az tozla çalışır ve çevre üzerinde büyük bir etki yaratmaz.

- Bıçak özel olarak yapılmıştır alaşım çelikten, güçlü ve dayanıklıdır.

Plastik parçalayıcı, aşağıdaki malzemeleri ezmek için uygundur.

- Çeşitli kaplar: plastik şişeler, plastik variller, demir davullar, ambalaj kutuları, ambalaj davulları.

- Kullanılmış cihazlar: TV, devre kartı, buzdolabı kabuğu ve diğerleri. e-atık geri dönüşümü.

- Borular: büyük boru, boru bağlantı elemanları, PE boru.

- Atık paletler: ahşap paletler, plastik paletler, forklift paletleri.

- Kullanılmış lastikler: otomobil lastikleri, kamyon lastikleri lastik geri dönüşümü.

- Hurda metal: araba kabuğu, alüminyum alaşımı, atık dökme alüminyum parçaları, motor muhafazası ve kalınlığı 5 mm'den az olan çelik levhalar.

- mutfak atıkları, evsel çöpler, tıbbi atıklar, biyolojik saman, bahçe çöpleri.

Lastik parçalama makinesinin çalışma prensibi

Plastik parçalama makinesi esas olarak bir parçalama bıçağı seti, bir taşıma kasası, bir kutu braket, bir besleme sistemi, bir güç sistemi ve bir elektrik kontrol sistemi ile bileşiktir. Malzeme, besleme sistemi aracılığıyla parçalanmış kutunun içine girer ve kutu parçalama bıçağını taşır. Malzeme, bıçaklar tarafından küçük parçalara parçalanır, sıkıştırılır ve kesilir. Son olarak, kutunun alt kısmından dışarı atılır.

Plastik parçalama makinelerinin avantajları

- Yüksek ezme gücüne sahip ağır döner bıçak. Kesiciler, uzun hizmet ömrü ile sağlam ve dayanıklı alaşım çelikten yapılmıştır.

- Çerçeve plakası kalındır ve yüksek güçlü torklara karşı dayanıklıdır.

- Plastik parçalayıcı makine, başlangıç, durdurma, tersine çevirme ve aşırı yük otomatik geri dönüş kontrolü işlevine sahip PLC akıllı kontrol kullanır. Malzeme kesme açısı otomatik olarak tersine çevrilebilir ve ayarlanabilir, bu da işlemi daha akıllı ve basit hale getirir.

- Düşük devir hızı, yüksek güçlü tork, düşük gürültü ve çevre koruma standartlarını karşılayan daha az toz.

- Kolay ayarlanabilir, düşük bakım maliyeti

- Kesici kalınlığı ve çene sayısı farklı malzemelere göre değiştirilebilir.

Müşterilerin özel gereksinimlerine göre farklı kesicileri yapılandırabiliriz, böylece makine daha mantıklı ve verimli çalışabilir. Elbette, farklı malzemelere uyacak birkaç set kesici de sipariş edebilirsiniz.

Shrdder makinesi parametreleri

| Modl | Dış boyut

(mm) |

Kırma odası boyutu(mm) | Bıçak çapı (mm) | Bıçak kalınlığı (mm) | Bıçak sayısı (adet) | Güç (kw) | Ağırlık (kg) |

| SL-500 | 2800×1300×1850 | 500×480 | 200 | 20 | 24 | 11×2 | 2200 |

| SL-800 | 3000×1300×1850 | 800×480 | 200 | 20 | 40 | 22×2 | 2500 |

| SL-1000 | 3300×1900×2200 | 1000×690 | 300 | 40 | 24 | 30×2 | 5200 |

| SL-1200 | 3600×2000×2200 | 1200×690 | 300 | 40 | 30 | 37×2 | 6400 |

| SL-1500 | 4180×2100×2400 | 1500×850 | 550 | 50/75 | 30/20 | 45×2 | 9000 |

| SL-1800 | 5800×2400×3300 | 1800×1206 | 550 | 50/75 | 36/24 | 55×2 | 13600 |

| SL-2000 | 6400×2700×3500 | 2000×1490 | 600 | 50/75 | 40/26 | 90×2 | 20100 |

| SL-2500 | 7500×3200×3800 | 2500×1800 | 600 | 75/100 | 32/24 | 110×2 | 25000 |

| SL-3000 | 8600×3500×4000 | 3000×1800 | 600 | 75/100 | 40/30 | 132×2 | 31000 |

Sıcak Ürün

Plastik Lavabo Yüzer Ayırma Yıkama Tankı

Plastik lavabolar için flotasyon ayırma yıkama tankımız…

Plastik film soğuk yıkama durulama tankı

Durulama tankı, durulama için kullanılır…

HDPE PP için Sert Plastik Geri Dönüşüm Hatları

HDPE PP ve… için plastik geri dönüşüm hatları

Dikey köpük kesme makinesi

Dikey köpük kesme makinesi, … için özeldir.

Soğutma tankı | Plastik soğutma makinesi

Plastik soğutma tankı çok önemlidir…

Otomatik besleme makinesi | Plastik geri dönüşüm için zorunlu besleyici

Bu otomatik besleme makinesi, simüle etmek için tasarlanmıştır…

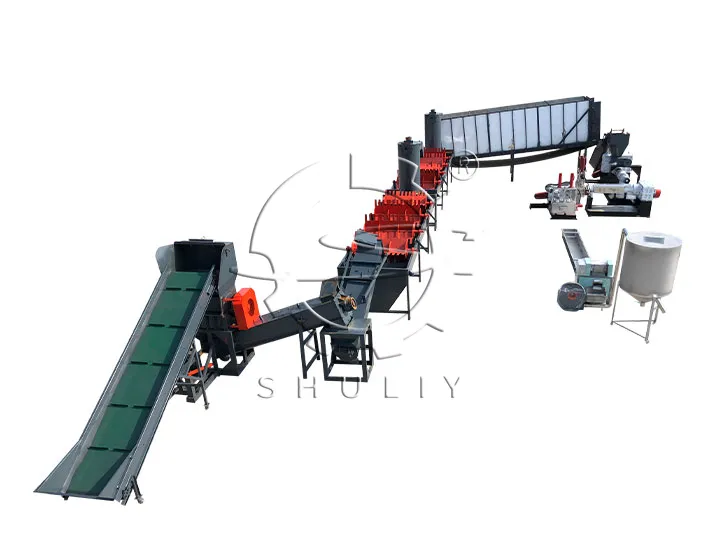

Kauçuk tozu üretim hattı | Atık lastik geri dönüşüm tesisi

Kauçuk tozu işleme hattı, özel olarak…

Lif Kesme Makinesi | Atık kumaş kesimi için Lif Parçalayıcı

Lif kesme makinesi, yıpranmış giysileri kesebilir…

Metal lastik parçalama için plastik parçalama makinesi

Plastik parçalama makinesi esas olarak prensibi kullanır…