reciclagem de filme laminado

Filmes laminados são materiais compostos feitos pela união de duas ou mais camadas de diferentes materiais, como plástico, papel ou metal, utilizando adesivos ou calor. Esse processo melhora as propriedades das camadas individuais, resultando em um material versátil amplamente utilizado em várias indústrias. Filmes laminados oferecem funcionalidade, durabilidade e apelo estético aprimorados, tornando-os essenciais na embalagem e fabricação modernas.

Aplicação de filme laminado

Filmes laminados são utilizados em uma ampla gama de indústrias, graças às suas propriedades versáteis. Algumas das principais aplicações incluem:

Embalagens de Alimentos: Filmes laminados são amplamente utilizados em embalagens de alimentos devido às suas propriedades de barreira superiores. Eles ajudam a prolongar a vida útil de produtos perecíveis, protegem contra contaminação e preservam sabores e aromas. Usos comuns incluem embalagens de salgadinhos, bolsas seladas a vácuo e embalagens de refeições prontas para consumo.

Embalagens Farmacêuticas: Na indústria farmacêutica, filmes laminados fornecem a proteção necessária contra umidade, luz e ar, garantindo a estabilidade e eficácia dos medicamentos. Eles são usados em blisters, sachês e embalagens em tiras para comprimidos, cápsulas e pós.

Aplicação Industrial: Filmes laminados também são usados em aplicações industriais, como isolamento, revestimentos protetores e materiais de embalagem. Sua resistência e resistência a fatores ambientais os tornam adequados para proteger produtos durante o armazenamento e transporte.

Filme laminado pode ser reciclado

O filme laminado inclui HDPE, LDPE, LLPDE, BOPP, CPP, OPP ou EVA. Quando se trata de alimentos (especialmente alimentos expandidos) e embalagens de doces, esses sacos plásticos de embalagem sempre incluem uma camada metalizada. Filmes laminados podem ser reciclados.

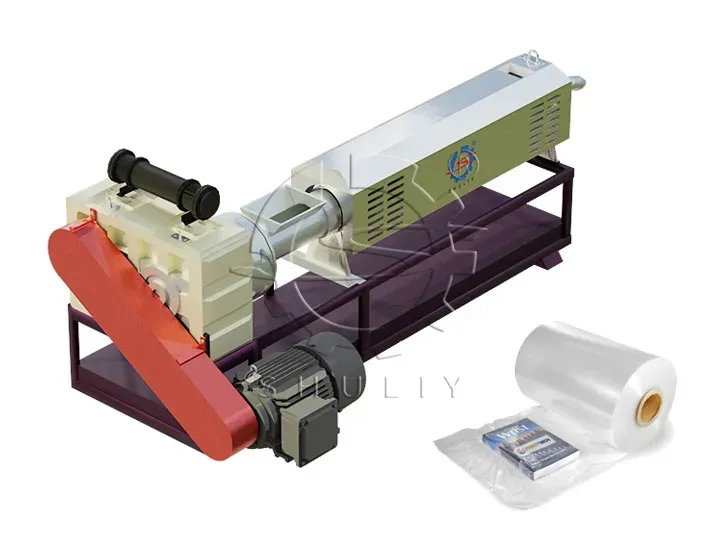

Máquinas de reciclagem projetadas para filme laminado

As linhas de reciclagem de plásticos altamente eficientes da Shuliy e suas configurações associadas são projetadas para reprocessar sucata de filme laminado. Comparado ao filme de PE comum, os moldados compostos são mais difíceis de cortar devido à sua alta resistência à tração.

Nossos novos trituradores de plástico foram especificamente modificados e aprimorados para este fim, e os pellets de alta qualidade feitos do material laminado permitem que os produtores os reutilizem em linhas de produção para moldagem por injeção, termoformagem, extrusão ou outras aplicações.

Os parafusos de granuladores da Shuliy para filmes laminados são cuidadosamente projetados para processar eficientemente vários materiais, incluindo sucata de filme laminado, metalizado e totalmente impresso. Este design criativo permite que o parafuso do granulador processe suavemente o material reciclado sem causar desnaturação ou degradação do plástico, garantindo a produção de pellets de plástico de alta qualidade.