Por que a Lavagem Quente é o "Molho Secreto" para Flocos de rPET de Alta Pureza

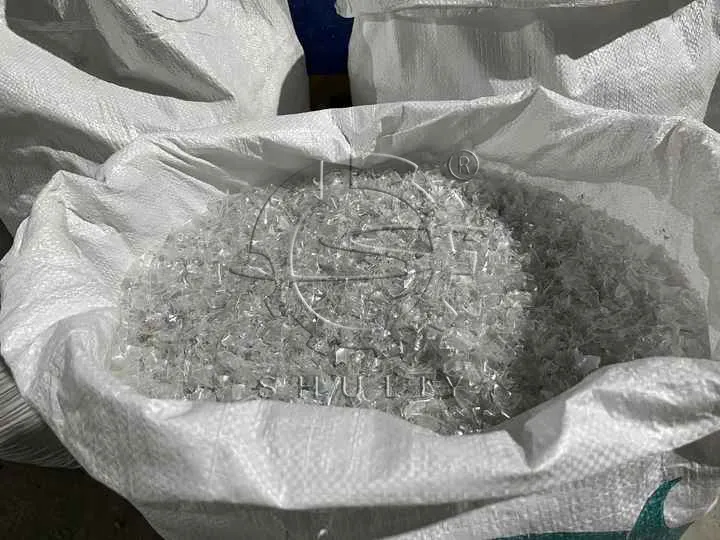

In the world of plastic recycling, the difference between “low-grade” and “premium” lies in one stage: the Hot wash PET line. If you aim for high purity rPET flakes suitable for the textile or bottle-to-bottle industry, cold washing simply won’t cut it.

The Hot Washing process typically operates between 85-95°C. Why this specific range? At these temperatures, combined with alkaline detergents (caustic soda), the stubborn glue residues from labels and organic contaminants from drinks are effectively dissolved.

Critical Insight: A common mistake is exceeding 100°C, which can degrade the PET’s intrinsic viscosity (IV), making it useless for fiber spinning. Our dual-tank system ensures consistent residence time and temperature stability, delivering flakes with a neutral pH and zero oil residue. This is the gold standard for rPET quality standards.