塑料颗粒机的功能是什么?

塑料造粒机是一项伟大的发明,它不仅为用户创造了效益,也为环境保护做出了重大贡献。过去,废弃塑料通常通过焚烧和填埋来处理,但这两种方式都容易破坏我们的生态环境。

如何将塑料转化为颗粒?(颗粒化过程)

废弃塑料通过塑料破碎机进行破碎,然后通过自动化提升系统输送到送料机。送料机随后将物料送入塑料造粒机。物料进入造粒机后,通过螺杆的压缩和外部加热机制进行混合和再塑化。

然后,塑料线材将通过造粒机的模头挤出。冷却水箱可以通过冷水快速冷却塑料并使其固化。冷却后,它们将通过颗粒切割机切割成更小、尺寸均匀的颗粒。

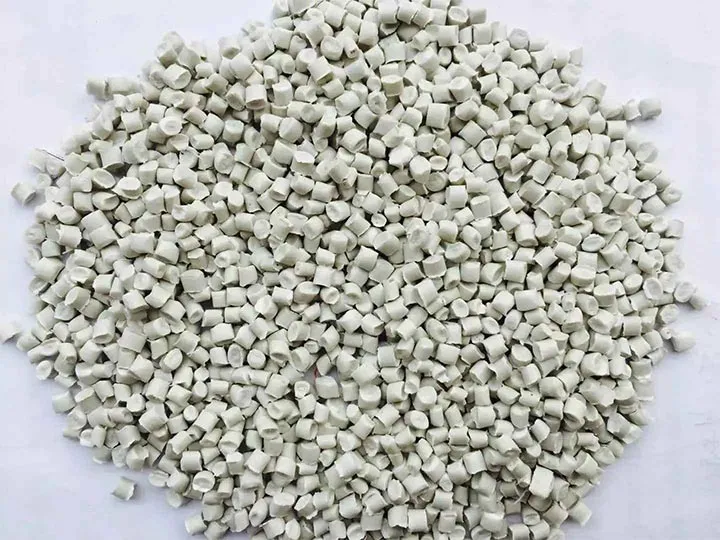

您获得的最终颗粒

高质量塑料颗粒的特点是颗粒大小和形状均匀,化学性质高度稳定,杂质含量低,并经过严格的质量控制,以确保它们满足特定的应用要求。这些颗粒通常表现出良好的流动性、耐热性和机械性能,因此广泛用于各种塑料产品的生产。

塑料颗粒化设备的应用

对于吹膜生产商

从吹膜、膜卷和薄膜中剩余的边缘废料可以通过简单的过程高效回收。高质量、均匀尺寸的再生颗粒几乎与原料相同,可以直接放回膜生产线。

对于PP编织袋/SAP/纤维丝生产商

在生产PP编织袋、PP拉菲亚、无纺布、集装袋、PP编织袋、PP绳等过程中,会产生内部(后工业)废料。通过工业造粒机回收的PP颗粒可以重新用于薄膜生产。

对于塑料回收中心

塑料回收中心和回收工厂收集消费后和工业后废料。这些塑料更加异质且质量较差。经过一系列处理,如分类、清洗和粉碎,回收工厂将通过添加母料或添加剂来改善颗粒质量。

塑料废物的前期处理造成了哪些损害?

通常情况下,填埋处理后的废塑料需要数百万年才能完全降解。在此漫长过程中,废塑料很容易污染地下水,对当地环境造成无法估量的损害。如果我们选择焚烧处理废塑料,很容易造成大气环境的破坏。燃烧塑料会产生有毒气体。例如,燃烧聚苯乙烯会产生甲苯。少量甲苯会导致失明和吸入性症状。燃烧PVC也会产生一些有毒气体,例如氯化氢。此外,高温环境还会导致塑料分解产生苯环等有毒成分。因此,使用塑料造粒机进行塑料回收势在必行。

塑料颗粒机视频

视频展示了1000kg/h的塑料造粒生产线,主要的回收设备是塑料薄膜破碎机、30米的清洗水箱、SL-220塑料造粒机和颗粒切割机。

我们还可以为您的特殊需求提供包装机器。以下视频中的颗粒被包装成每袋10公斤。

重要的 塑料颗粒机的作用:

作为一种新的塑料再加工方法,塑料颗粒化无疑将成为未来塑料回收的新方向,它使用塑料颗粒机来避免白色污染、焚烧等问题。

随着时代的发展,白色污染日益严重,废塑料无处不在,这不仅浪费了资源,还严重污染了环境。因此,废塑料的颗粒化为我们提供了广阔的投资利润空间。领先一步必将为我们带来良好的回报。这个永不饱和的市场最大化了你的投资。

废塑料颗粒机现在得到了大多数客户的认可。使用塑料颗粒机回收和造粒塑料是一种废塑料发展的新模式。该机器主要用于废塑料薄膜、塑料块、PP编织袋、编织袋、农业袋、花盆、桶、饮料瓶、家具、日用品等的造粒。它适用于大多数常见的废塑料。它是废塑料回收行业中使用最广泛、最受欢迎的塑料回收机器。

塑料颗粒化能力

我们的塑料造粒机具有产量大、使用寿命长、占地面积小等特点。塑料造粒机每小时可处理约1000-500公斤的废塑料,是塑料回收行业的理想设备。如果您对我们的塑料造粒机或完整的回收生产线感兴趣,请在下方给我们留言。

工业回收颗粒机出售

舒利机械已经制造和销售塑料颗粒机超过二十年,我们帮助许多客户建立塑料回收厂,并通过销售高质量的塑料颗粒获得利润。

如果您也对塑料回收机和塑料造粒机感兴趣,请通过我们的网站弹窗给我们发送消息。我们的项目经理将在24小时内与您联系,满足您的塑料造粒需求。