如何处理塑料造粒机产生的废气

在塑料加工过程中,特别是废塑料回收加工中,经过分类、破碎和清洗的废塑料将被送往废塑料造粒机进行高温熔融和过滤挤出。在此过程中,各种程度的废烟排放成为二次环境污染的主要来源。如果我们不对废气进行处理就排放,将严重污染环境。那么我们应该如何处理废塑料造粒机产生的废气呢?

废气过滤器

废气过滤器可以与废塑料颗粒机配合使用,使烟雾去除率超过98%,从而实现废塑料的真正环保处理。高效气体过滤机集成了混合水解烟雾去除系统、水环真空烟雾去除系统、微过滤烟雾去除系统、多级气味去除系统以及多个自动监测和控制系统。它具有烟雾去除、蒸汽去除、气味去除、除尘和颗粒去除等多种功能。

生物颗粒处理

工业生产中产生的废气进入除尘系统进行处理,固体颗粒在进入除臭装置之前被去除。在除臭装置中,废气中的气味在特别培养的微生物的作用下被降解和净化到大气中。生物方法是通过微生物和生物过滤来处理和降解有臭味的废气。在生物降解废气中的无机物、挥发性有机化合物和其他污染物后,最终转化为无毒无害的二氧化碳和水,从而达到净化的目的。

塑料颗粒机废气过滤器主要用于工业生产中的气味净化设备

1. 在日常使用中,微生物除臭剂除了因空气阻力消耗少量电力外,节能效果显著。

2. 除了每年左右更换和补充填料及微生物种类外,没有其他维护成本,气体过滤器的成本非常低。

3. 整个系统在负压下工作,没有废气泄漏。

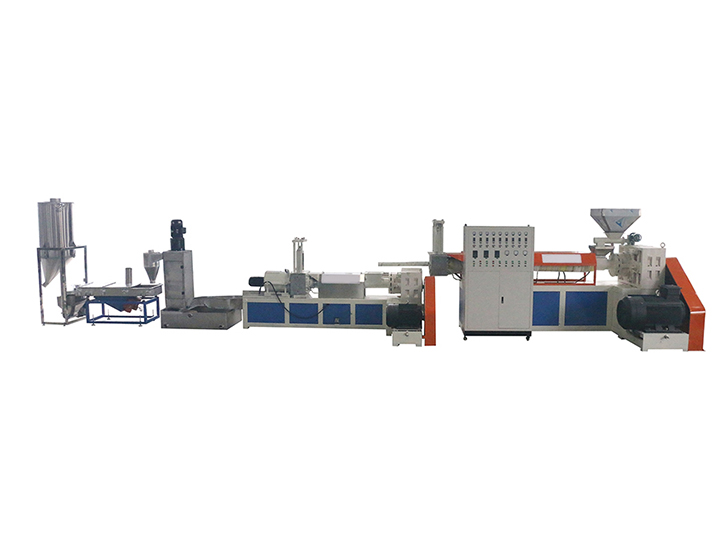

以上是关于如何处理塑料造粒线产生的废气的处理方法,供您参考。如果您对我们的机器感兴趣,欢迎到我们的工厂参观。