摩擦洗涤机的工作过程

作为一种塑料清洗设备,高速摩擦清洗机在清洗设备的使用中具有其独特的功能和优势。

在塑料回收线中,高速旋转的螺杆使物料与水充分摩擦,物料表面的杂质(泥土、沙子、树叶、纸浆)被分离,脏污物通过清水冲洗。独特的水喷射设计和高速运行的螺杆确保了出色的清洗效果。

塑料摩擦洗涤器的功能

1. 利用机械摩擦去除瓶片上的油、胶、纸浆及其他杂质。

2. 移动水冲洗,可以通过过滤网排出沉淀物和纸浆,达到非常理想的清洗效果。

3. 根据污染程度控制材料的清洗时间。

洗涤机的结构

PET瓶摩擦洗涤机的机身由主机、电机、底架、水入口、进料口、排料口等组成。机身底部是细网过滤器,顶部有外部水入口,物料从进料口进入,高速旋转的螺杆使物料与流动水充分摩擦,从而实现对物料的完全清洗。

摩擦洗衣机的特点

摩擦洗衣机用于废塑料的清洗。它具有占地小、操作简单和产量高的优点。可以作为塑料清洗线的配套设备。

摩擦洗衣机参数

| 项目名称 | 塑料摩擦洗衣机 |

| 容量 | 400-600公斤/小时 |

| 电力 | 7.5千瓦/380伏/50赫兹/三相 |

| 洗涤管直径 | 0.4米 |

| 进料口 | 40*40厘米 |

| 机器尺寸 | 4.1*0.6*1.4米 |

| 机器重量 | 560千克 |

相关的PET瓶清洗线

整套塑料瓶回收设备包括PET瓶标签去除机、塑料破碎机、沉浮分离清洗槽、自动输送机等。我们的PET回收设备是大多数项目的理想解决方案。但我们也可根据您的特殊需求提供定制化解决方案。

热销产品

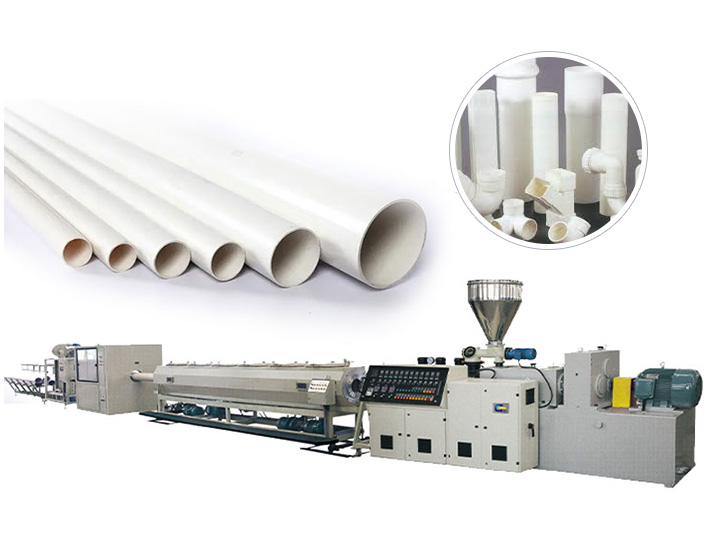

塑料管制造机 | PPR HDPE PVC管生产线

我们公司提供全系列塑料…

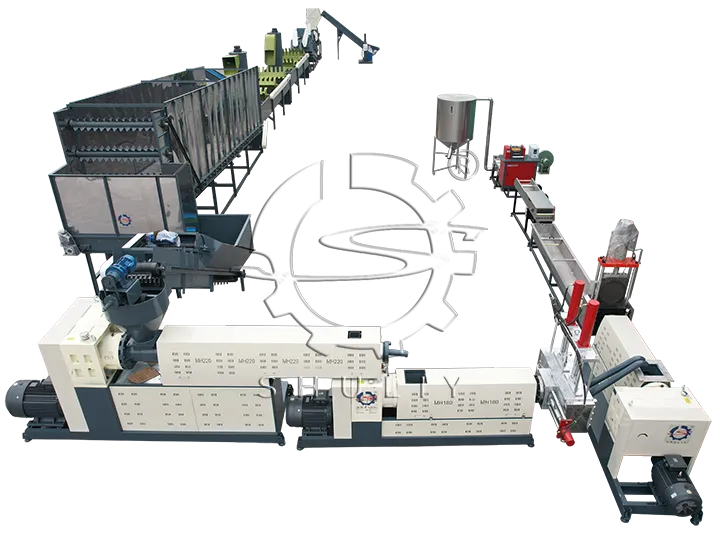

塑料薄膜回收机

塑料薄膜回收机效率高…

废旧轮胎回收线 | 橡胶颗粒制造机

废旧轮胎回收线采用先进的轮胎…

轮胎侧壁切割机

TCC-1250 轮胎侧壁切割机是一款…

塑料颗粒包装机 | 包装机

废塑料在处理后需要完全包装…

冷却罐 | 颗粒冷却机

塑料冷却罐是非常重要的…

PET瓶片热水洗涤槽

热水洗涤槽适用于…

开创性的废塑料水环造粒机

由于水环的优点…

精密橡胶块切割机:轮胎回收线的双模型号

在半自动回收线上,…的过程