Frictional washing machine for PET bottle recycling

Plastic frictional washer machine

Frictional washing machine for PET bottle recycling

Plastic frictional washer machine

Working process of the frictional washing machine

As one kind of plastic cleaning equipment, a high-speed frictional washing machine has its own unique function and advantages in the use of cleaning equipment.

In the plastic recycling line, the high-speed rotating screw allows the material to be fully rubbed with water, and the impurities (soil, sand, leaves, paper pulp) on the surface of the material are separated, and the dirty goods are washed with clean water. Unique water spraying design and high-speed running screw ensure an excellent cleaning effect.

The function of the plastic friction washer

1. Use mechanical friction to remove the oil, glue, paper pulp, and other impurities on the bottle flakes.

2. Moving water flushing, can discharge the sediment and pulp through the filter screen, achieving a very ideal cleaning effect.

3. Control the cleaning time of material according to the degree of contamination.

Structures of the scrubbing machine

The PET bottle frictional washing machine body is composed of the main engine, motor, foot frame, water inlet, feeding inlet, discharge hole, and so on. The bottom of the body is a fine mesh filter, there is an external water inlet on the top, and materials are entered from the feeding inlet, the high-speed rotating screw allows the material to be fully rubbed with the running water, then achieve to clean the material completely.

Features of the frictional washing machine

The frictional washing machine is applied to the cleaning of waste plastics. It has the advantages of small occupation, simple operation, and high yield. It can be used as the supporting equipment of a plastic cleaning line.

Frictional washing machine parameters

| Item name | Plastic frictional washing machine |

| Capacity | 400-600kg/h |

| Power | 7.5kw/380-v/50hz/3ph |

| Washing tube diameter | 0.4m |

| Feeding inlet | 40*40cm |

| Machine size | 4.1*0.6*1.4m |

| Machine weight | 560kg |

Related PET bottle washing line

The whole plastic bottle recycling plant includes PET bottle label remover, plastic crusher, sink float separation washing tank,automatic conveyors and so on. Our PET recycling plant is an ideal solution for most projects. But customized solutions also are provided for your special demands.

Hot Product

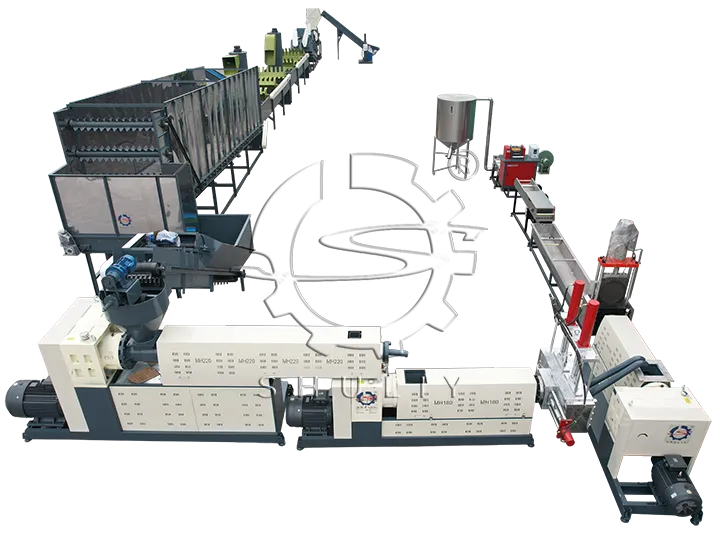

Strand Pelletizer Machine for Rigid Plastic Recycling

Strand pelletizer machine offer recycled pelletizing technology for…

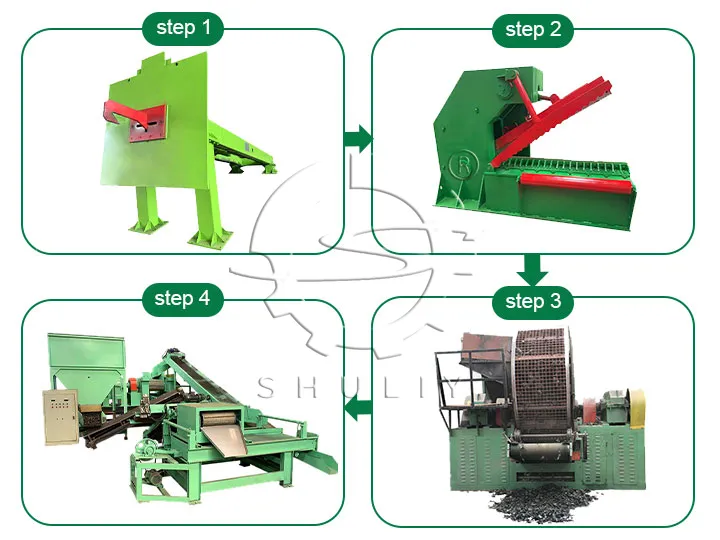

Automatic rubber powder production line

The automatic rubber powder production line is used…

Plastic Bag Shredder Grinder Machine

A plastic bag shredder is a kind of…

Plastic Film Recycling Machine

The plastic film recycling machine is highly efficient…

Tire Sidewall Cutter Machine

The TCC-1250 tire sidewall cutter machine is a…

Plastic Pelletizing Machine

The plastic film pelletizing machine can also be…

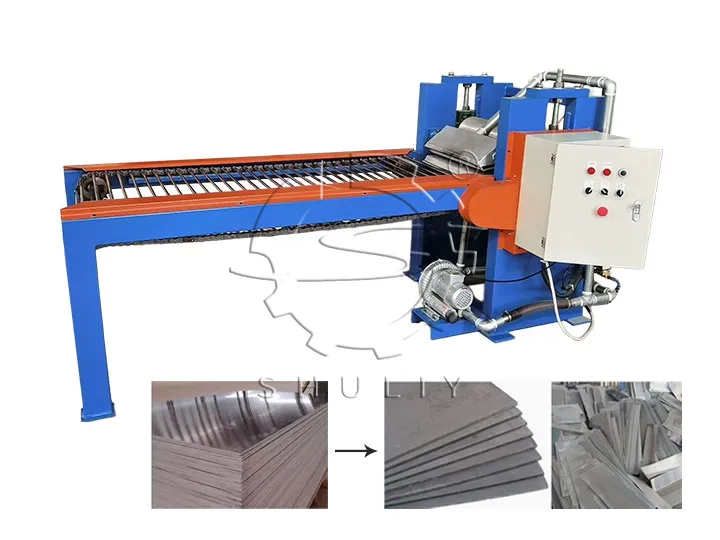

Shuliy SL-Series ACP Recycling Machine

Scrap Aluminum Composite Panels (ACP) from construction and…

Plastic pellet storage bin | Recycled plastic granules silo

The plastic pellet storage bin is an alternative…

Turnkey OTR Tire Recycling Plant for Mining & Heavy Duty Tires

The disposal of Off-the-Road (OTR) tires presents a…