PET Bottle Crushing Machine

PET bottle scrap grinding machine | Plastic bottle shredding machine

PET Bottle Crushing Machine

PET bottle scrap grinding machine | Plastic bottle shredding machine

Features at a Glance

PET bottle crushing machine plays a very important role in plastic bottle recycling lines. It is also called a PET bottle scrap grinding machine. the capacity of the grinder is about 200-2000kg/h. The operation is easy, and the grinder machine price is favorable. Shuliy will suggest the ideal model for you according to your collected bottles.

Instruction of PET bottle crushing machine

The PET plastic bottle crusher is used for crushing PET bottles, PVC, etc. The plastic crusher machine design is reasonable, it can crush the raw material into small flakes to recycle the waste plastic. The machine is suitable for the PET bottles recycling production line.

The feature of waste plastic crusher

- The PET bottle crushing machine is widely used and can crush PET bottles and PVC, also PP/PE.

- The plastic bottle crusher has special alloy steel material blades and high cutting speed, the blades are durable and wearable.

- The PET bottle crushing machine is easy to operate and can save labor.

How to operate PET bottle crushing machine

- Before starting the PET bottle crushing machine, please ensure everything is correct.

- After the crusher machine finishes its work, turn it off in time.

- Inspect and repair plastic bottler crusher regularly.

Installation of PET scrap grinding machine blades

- Install the rotary cutter of the PET bottle crushing machine horizontally.

- Install the fixed knife horizontally. It is best to rotate it. The fixed knife rotates by hand and has a slight friction sound.

- Install the remaining rotary cutters with frictional sounds.

- Tighten the rotary cutter bolts.

- Exit the fixed knife and tighten the fixed bolt according to the clearance between the fixed blade and the rotary cutter.

- The other fixed knife is installed on the reverse side, and the gap is equal to the opposite side. Fixed and rotary knife clearance: the gap of crushed general hardness block is about 3 mm, the gap of crushed integrated waste plastic products is about 1.5 mm, and the gap of special material can be about 1 mm.

Water Bottle Crusher Technical Specifications

Our PET bottle crushers are engineered for reliability and high performance. The machine body is constructed from heavy-duty A3 steel plate, ensuring a strong structure and minimal vibration during operation. The core of the machine, the main rotor, undergoes a dynamic balance test to guarantee smooth, high-speed rotation.

A key design feature is the outboard bearing seats. This places the main bearings outside the crushing chamber, effectively protecting them from dust and water contamination, which significantly extends their service life and simplifies maintenance.

We offer a range of models with capacities from 200 kg/h up to 2500 kg/h, powered by high-quality motors from brands like Siemens or Wanan (customizable). For operational safety, all models are equipped with motor current overload protection and safety limit switches.

If you are interested in the water bottle crusher, send us a message by our website form.

| Parameter | Model: SL-600 | Model: SL-800 | Model: SL-1000 | Model: SL-1200 |

|---|---|---|---|---|

| Capacity (kg/h) | 800 – 1000 | ~ 1200 | ~ 1500 | 2000 – 2500 |

| Main Motor Power (kW) | 22 / 30 | 37 / 45 | 55 / 75 | 75 / 90 |

| Rotor Diameter (mm) | 377 | 425 | 425 | 500 |

| Rotating Blades (pcs) | 8 | 10 | 12 | 12 |

| Fixed Blades (pcs) | 4 | 4 | 4 | 4 |

| Blade Material Options | 9CrSi / SKD-11 / D2 | 9CrSi / SKD-11 / D2 | 9CrSi / SKD-11 / D2 | 9CrSi / SKD-11 / D2 |

| Screen Mesh Size (mm) | 16 – 20 (for PET bottles) | 16 – 20 (for PET bottles) | 16 – 20 (for PET bottles) | 16 – 20 (for PET bottles) |

| Weight (kg) | ~ 1500 | ~ 2500 | ~ 3500 | ~ 4500 |

| Machine Body Material | Carbon Steel | Carbon Steel | Carbon Steel | Carbon Steel |

Notes: The SL-500 model crusher with a capacity of 200-500 kg/h and 11kW motor is also available for smaller-scale operations.

Related machines of plastic bottle shredder machine

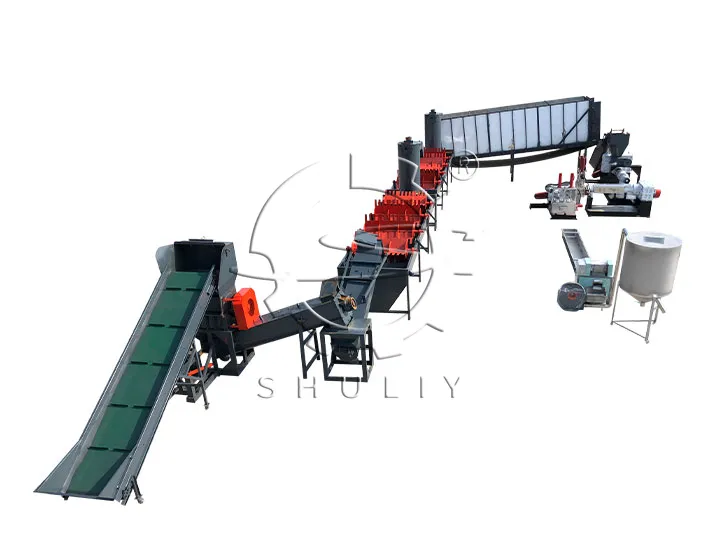

The plastic bottle shredder machine is an essential recycling machinery in a complete PET bottle recycling line.

The first step of recycling PET bottle is removing the outside labels on the bottle body by a label remover machine, then crushing bottles by a plastic bottle shredder. Thirdly, separating the other type of plastic like PP PE from PET by a sink floating tank. The last step is washing PET flakes by a washing system, including hot washing, rinsing, frictional washing method.

If you are interested in the plastic bottle recycling project , welcome to contact us, our project manager will send you each machine introduction and more details in 24 hours.

Prospect of the PET bottle crushing machine

Plastic crusher is an environmentally friendly recycling machine that is very much needed in society today. The PET bottle crushing machine can crush most of the waste plastic. Plastic crushers can reuse some waste plastic that poses a major threat to the environment. This machine is very popular in Southeast Asia, South Asia, Africa, the Middle East, and Central America. If you are interested in the machine, please leave a message below. We will provide customized machines according to the needs of our customers.

Moreover, if your materials is PP PE, we have another professional shredder for PP PE. Send us a message by the website form. We will send you machine details in 24 hours.

Hot Product

Rigid Plastic Shredder Machine

Shuliy rigid plastic shredder machine is also called…

Rigid plastic recycling lines for HDPE PP

The plastic recycling lines for HDPE PP and…

Plastic pellet cutting machine | Plastic granule cutter

This plastic pellet cutting machine is the last…

Belt climbing conveyor | Inclined transport machine

A belt climbing conveyor is an essential machine…

Automatic feeding machine | Forced feeder for plastic recycling

This automatic feeding machine is designed to simulate…

Pioneering waste plastic water ring pelletizer

Due to the advantages of the water ring…

Tire Sidewall Cutter Machine

The TCC-1250 tire sidewall cutter machine is a…

EPE EPS Foam Granulating Line

The EPS foam granulating line is suitable for…

Waste Gas Filter | Plastic Recycling Filtration System

Pure water-flue gas treatment is a modern standard…