Plastic crusher machine for recycling plants worldwide

PET / PE / PP waste crushing machine | Crusher for bottles, films, drums size reduction

Plastic crusher machine for recycling plants worldwide

PET / PE / PP waste crushing machine | Crusher for bottles, films, drums size reduction

The plastic crusher machine sold by Shuliy Machinery has wide applications and can be used to crush and recycle plastic materials with different shapes. The processing technology is mature, and important parts such as the box body and the blade holder are processed with high precision.

The design and structure of the plastic crusher are reasonable, easy to operate, energy-saving, durable, efficient, and economical. Safety devices are set to ensure safe operation and the double-layer soundproof design of the feeding hopper reduces noise. The plastic crusher machine has a stable operation, low noise, no dust pollution, uniform granulation, and a good crushing effect.

It is a multi-purpose plastic crusher, adopting a sealed bearing so that the bearing rotation can run smoothly for a long time. The design of the blade is reasonable, which enables the granule is uniform.

What materials can our crusher for sale handle?

Our plastic crusher machine for sale is engineered to process a wide variety of plastic waste materials, making it an ideal size reduction solution for different recycling applications.

- PET bottles & bottle caps – Ideal for post-consumer PET bottle recycling, including bottles with labels or small residual liquids.

- HDPE drums & chemical containers – Easily crushes rigid containers used in oil, detergent, and chemical industries.

- Plastic films & bags (LDPE/LLDPE/PP) – When paired with a blower or conveyor, the plastic film grinder efficiently handles soft materials like agricultural film, stretch film, bubble wrap, and shopping bags.

- Woven bags & jumbo sacks (PP/raffia) – Used in fertilizer, grain, cement packaging; crushing them improves storage and speeds up reprocessing.

- Plastic pallets & crates – For logistics companies or warehouse operations with damaged or discarded plastic transport items, the pallet crusher can do a great job on the shredding task.

If you don’t sure wheather your materials can be pulverized or not,you can send us a photo to us, we will give you professional recycling suggestions. Moreover, you can also get crusher model suggestions based on your material & output needs.

Plastic crusher for sale features

1. The base of the plastic crusher for sale is welded by steel, which is sturdy and durable.

2. The spindle has high precision.

3. High-quality chrome steel double-edged tool has a sharp edge and can be changed easily. The processing technology is mature, and the important parts such as the box and the tool holder are highly matched.

4. The tool holder is novel in design, and the claw type holder is spirally distributed, which can disperse the scrap material and reduce the impact force when the scrap material is broken. Such a design can ensure that the crushing force of each knife is more uniform.

5. The design of plastic crusher for sale is very reasonable, easy to repair and clean, and it has a two-layer structure. Soundproof materials can reduce noise.

6. Customers can choose accessories according to their needs.

7. The blade of this water bottle crusher machine is fit for crushing hard raw materials such as PP, PE, PET, PVC sheet, plastic water bottle, film, braid bag, leather, sole, etc.

8. Claw knife type is suitable for crushing polyethylene, horn, wood, ceramic, nylon, PC, PA, ABS, PET, and other materials.

Other applications: plastics factory, electronics factory, plastic container factory, lighting factory, shoe factory, electrical appliance factory, auto parts factory, luggage factory, pumping factory, waste recycling factory, plastic toy factory, plastic kitchen factory, etc.

The details of plastic crusher

- Control panel: The button is used to control the switch, which is easy to operate and intuitive.

- Inlet: The feeding port is thickened to increase the working speed, and is also durable. Double-layer steel plates can reduce noise.

- Knife claw: 14mm thickened- steel plate can effectively reduce the noise generated by vibration, and is durable. The cutter shaft is equipped with high efficiency and high power.

- Motor: The motor has low-temperature rise, stable performance, low failure rate, high efficiency, and long service life.

- Hopper: it is made of stainless steel with corrosion resistance, no water leakage, no oil leakage, and long service life. In addition, there is a direction wheel that is light in weight, reducing the labor of the user.

The correct use of plastic crusher

1. The plastic crusher and power unit should be installed firmly. It needs to be fixed on a solid floor if working for a long time. Conversely, it should be installed on a base made of angle iron if you want to move it frequently.

2. After the crusher is installed, you need to check the fastening condition of each fastener. If it is loose, it needs to be tightened in time. Also, check whether the belt tightness is appropriate.

3. It is necessary to idle the machine for 2~3min before working, and the machine can be operated if there is no abnormal phenomenon.

4. Raw material should be placed evenly to prevent blockage, and it can not overload work for a long time. If there is vibration, noise, high temperature of the bearing, and external spraying, you shall stop the machine immediately, and continue working after troubleshooting.

Parameter of plastic crusher

| Model | SL400 | SL500 | SL600 | SL800 |

| Power(kw) | 7.5 | 11 | 15 | 22 |

| Grinding room(mm) | Φ246×400 | Φ265×500 | Φ280×600 | Φ410×800 |

| Rotating blade quality | 12 | 15 | 18 | 24 |

| Fixed blade quality | 2 | 4 | 4 | 8 |

| Grinding capacity | 400–600 | 460–650 | 600–800 | 800–1000 |

| Aperture of screen(mm) | Φ10 | Φ10 | Φ10 | Φ12 |

| Apperance(mm) | 130×90×170 | 140×100×165 | 145×125×172 | 150×140×180 |

| Weight(kg) | 660 | 870 | 1010 | 1250 |

Plastics processed by plastic crusher machines can be reprocessed into plastic pellets that can be used in many fields.

Not Sure Which Model Fits Your Material?

Let our engineers help! Send us a photo or description of your plastic material, maybe they are bottles, films, drums, runner scrap or other waste, we’ll recommend the best crusher model based on:

- Material thickness and hardness

- Desired output size (10–40mm)

- Daily output (kg/h)

- Plant layout or space restrictions

Feel free to leave your requirements on our popup message board, we will contact you and provide you customized crushing solution.

How much does a plastic crusher machine cost?

The plastic crusher machine price typically ranges from USD $2,500 to $8,000, depending on the model, motor power, material size, and output capacity.

Several factors influence the final cost: Model & Motor Power – Higher power models (e.g. 15kW–22kW) for large drums and pallets cost more than compact ones.

Blade configuration – Heavy-duty or alloy steel blades can increase durability and affect pricing.

Customization – Options like conveyor belts, screen mesh size, or voltage adaptation can impact cost.

Integrated systems – Crushers used with blowers or pelletizers may require layout adjustments.

If you want to know the specific price of one model crusher for sale, send us your material type and output requirement—we’ll recommend the best solution with a tailored quote.

Hot Product

Plastic Sink Float Separation Washing Tank

Our plastic sink float separation washing tank uses…

Belt climbing conveyor | Inclined transport machine

A belt climbing conveyor is an essential machine…

PET Bottle Crushing Machine

PET bottle crushing machine plays a very important…

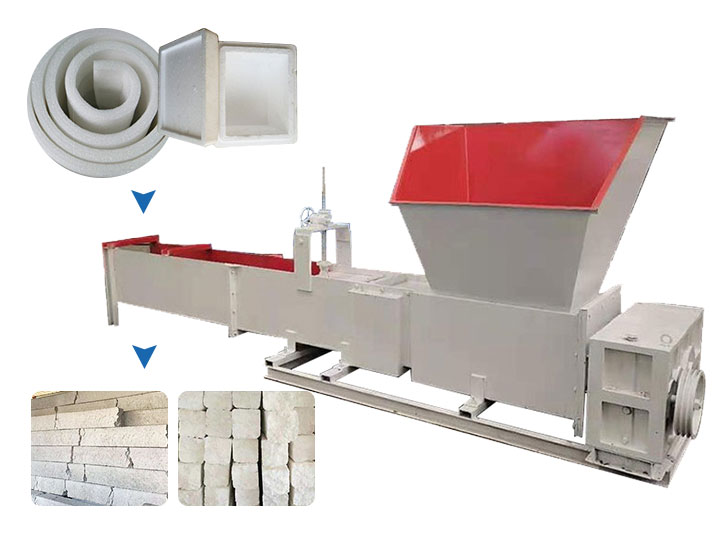

Vertical EPS foam compactor | Styrofoam recycling densifier

Vertical EPS foam compactor is one of the…

PET bottle label remover recycling machine

PET bottle label remover is indispensable for plastic…

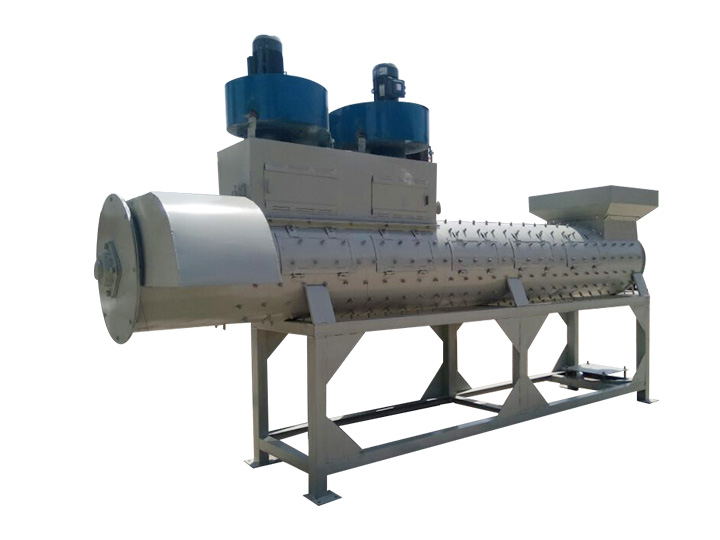

EPE Recycling Machine for Foam Pelletizing

Waste EPE foam pelletizing machine is suitable for…

Plastic Bag Shredder Grinder Machine

A plastic bag shredder is a kind of…

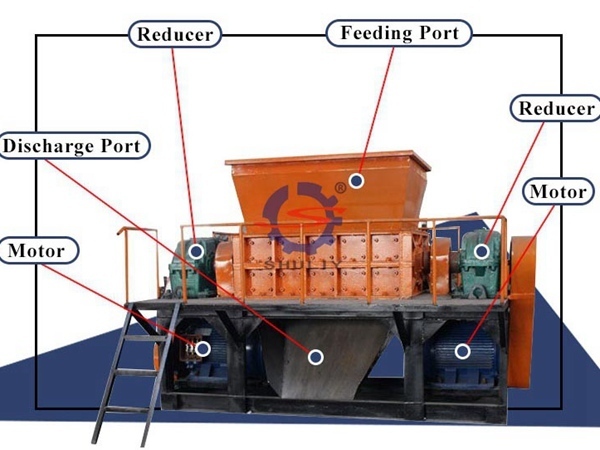

Plastic shredder machine for metal tire shredding

The plastic shredder machine mainly uses the principle…

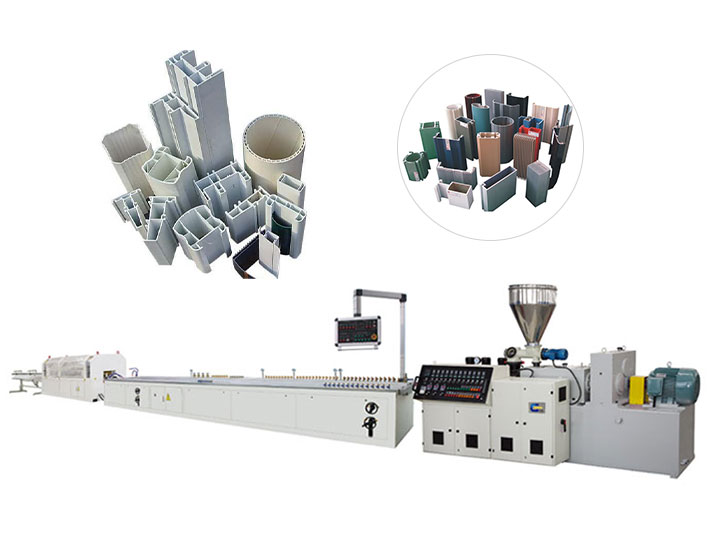

Plastic profile extrusion line | PVC ceiling making machine

Shuliy plastic profile extrustion line is a professional…