EPE EPS Foam Granulating Line

EPE styrofoam pelletizing machine | Plastic foam pelletizing line

EPE EPS Foam Granulating Line

EPE styrofoam pelletizing machine | Plastic foam pelletizing line

The EPS foam granulating line could process waste foam into particles. And these plastic particles could apply to make packaging, insulation, and other materials. The EPE styrofoam pelletizing machine includes a foam granulator machine, cooling tank, pellet cutting machine, control panel, and others. For the pre-processed machine, there are EPS foam melting machines, and EPE foam compactor machines, which could save space for transporting waste foam.

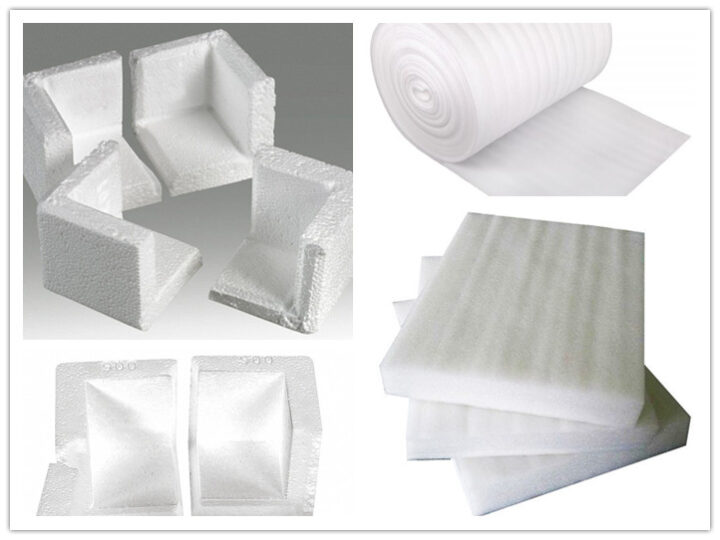

What are EPS polystyrene foam and EPE styrofoam?

EPS (Expanded Polystyrene) is a lightweight polymer. It uses polystyrene resin to add a foaming agent, and at the same time, it is heated to soften and generate gas, forming a rigid closed-cell structure foam.

This uniformly closed cavity structure makes the EPS have the characteristics of low water absorption, good heat preservation, lightweight, and high mechanical strength. EPS can be molded into shape, that is, it can be pre-expanded into particles, and then formed into various shapes in the mold. It has poor toughness, easy to break, and general cushioning performance.

EPE (Expandable Polyethylene) is commonly known as pearl cotton. The density is small, the flexibility is good, and the recovery rate is high. Excellent shockproof performance, independent bubble structure, low surface water absorption. Good impermeability. It is resistant to acid, alkali, salt, oil, and other organic solvents, and has excellent aging resistance. It does not flow at high temperatures and does not crack at low temperatures.

EPE can be extruded or foamed and can be made into plates, sheets, or pipes, and then punched and cut and bonded to form. It has good toughness, is not easy to break, and has good cushioning properties.

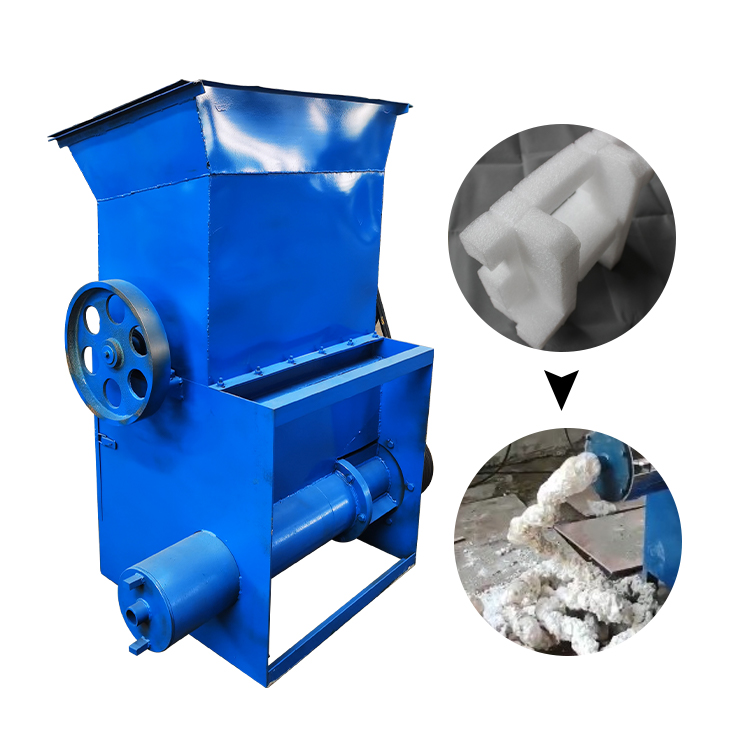

EPS Polystyrene Foam granulating line

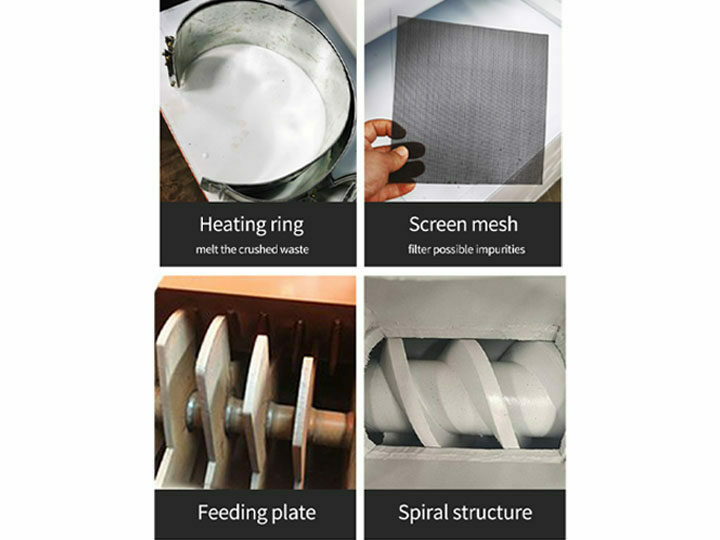

The EPS polystyrene foam recycling line could process waste foam made of polystyrene into particles. The line includes a granulator machine, water tank, pellet cutting machine, and a control cabinet. The main machine is an EPS foam granulator, which includes two machines, combining the functions of crushing and melting.

EPS foam granulator machine

- Model: 220+150

- Power:15kw+5.5kw

- Capacity:150-200kg/h

- Double reducer

- Electric mould as picture(change net without stopping machine)

This foam granulator machine includes a crusher, and a pellet making machine. This EPS foam granulation machine consists of an auxiliary machine, the main machine, a die head, a grinder. It has different types according to the output. Since EPS foam is prone to debris during processing, customers could cover the feed inlet with the cloth.

Water Tank

This cooling machine is used to cool the plastic pellet and send the pellet to the next step-plastic cutting machine. Customers could also customize the tank according to their demands, but the most common length is 3 meters.

Pellet cutting machine

This machine is used to cut the plastic strip into small pieces and the size of the pellet can be adjusted as your requirements.

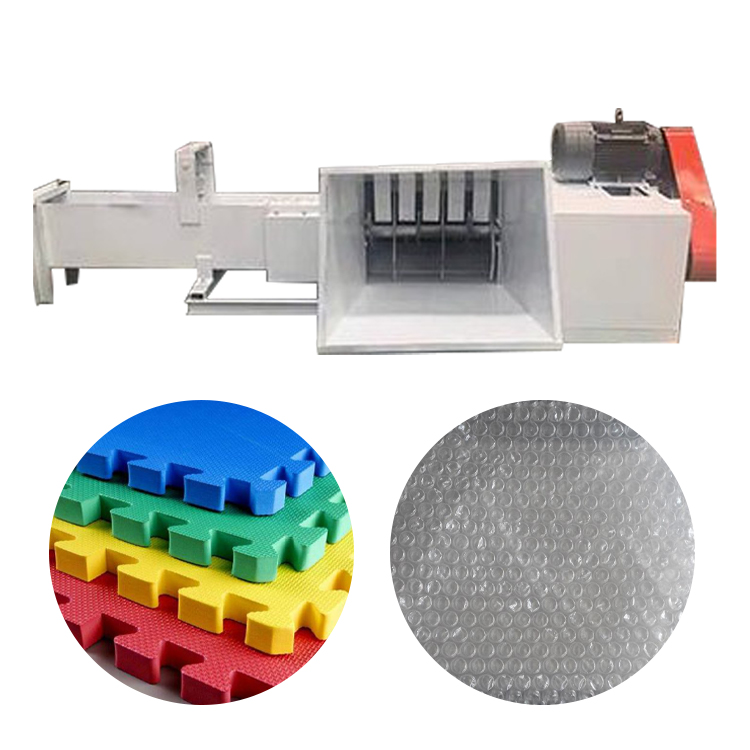

EPE Styrofoam pelletizing machine

These EPE styrofoam recycling machines includes a draught fan, an EPE foam pelleting making machine, a water tank, a pellet cutting machine, a control panel. And the foam granulator machine could crush and heat plastic foam.

Draught Fan

Blow up the foam so that the foam enters the inlet.

EPE foam pellet making machine

The raw material is heated and melted in this machine, and the melted foam is drawn through the die in the machine. This EPE foam pellet making machine is composed of a distribution cabinet, an inlet, guard, vent, die head. The foam pellet machine adopts a conical screw barrel with fast feeding speed and high output.

- Model SL-160

- Machine size:3400*2100*1600mm

- Inlet size:780*780mm

- Power:30kw

- Capacity:150-200kg/hour

- Heating method: heating ring

Read more anout our EPE foam recycling case:

- A Successful EPE granulating line Setup in Bulgaria

- EPE foam pellet machine Transforms Foam Waste into Valuable Resources in Mexico

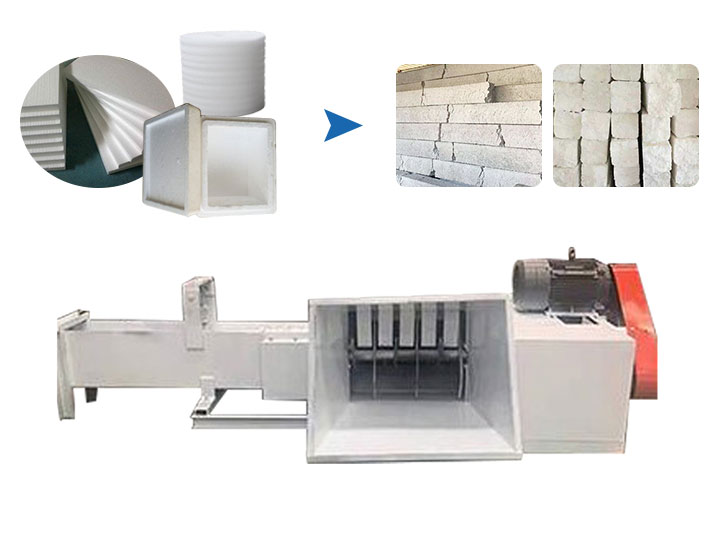

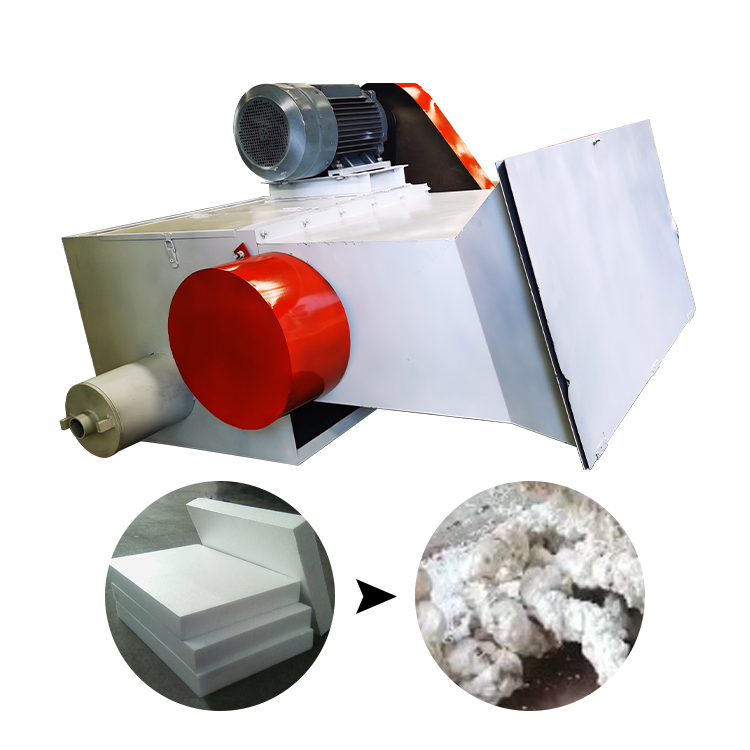

EPS foam melting machine

This styrofoam melting machine can melt waste foam into lumps, reduce the volume, and facilitate transportation. It has a large output, high efficiency, low dust, and noise, consumes less energy, easy to operate. The full temperature control of this melting machine can avoid the phenomenon of foam burning or not melting.

Size: 1500*800*1450mm

Feeding port size: 450*600mm

Motor: 15kw

Heating power: 3kw

Output: 100-150kgh

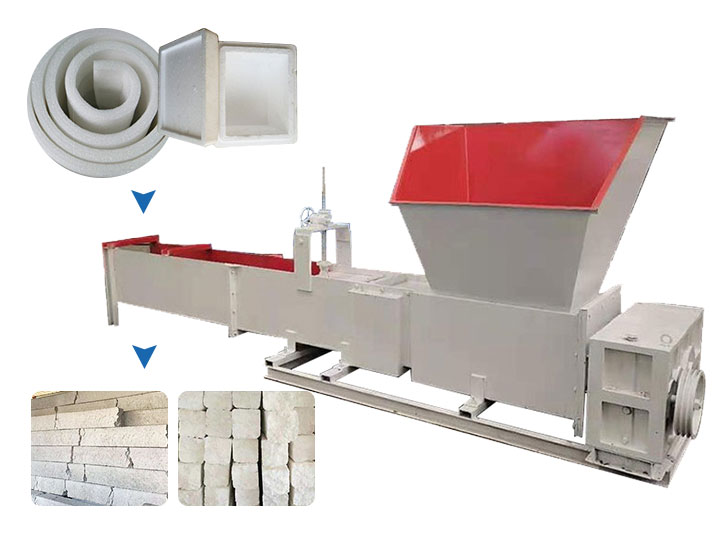

EPS foam compactor machine

The EPS foam compactor can crush the foam first and then extrudes it according to the spiral rotation. It can effectively double the volume of the foam and increase the density. It is convenient for the transportation and recycling of waste foam. There are two types of compactors, Vertical EPS foam compactor, and Horizontal EPS foam compactor.

Product features of EPE foam densifier

- Compression ratio of cold press: 40:1.

- High density after compaction, easy to transport.

- After compaction, it is easy to cut off, convenient for stacking and storing.

- The machine is simple, practical and easy to operate.

- Economical and environmentally friendly, cold-pressed treatment is smokeless and tasteless.

| Model | Dimensions | Inlet size | power | Capacity |

| Sl-300 | 3000*1400*1400mm | 1100*800mm | 11kw | 150kg/h |

| Sl-400 | 4600*1600*1600mm | 1200*1000mm | 22kw | 250kg/h |

| Model | Dimensions | Inlet size | power | Capacity |

| Sl-300 | 3000*1700*900mm | 830*760mm | 15kw | 175kg/h |

| Sl-400 | 4600*2800*1200mm | 870*860mm | 22kw | 300kg/h |

Operation Video of EPS EPE foam granulating recycling machines

Global customers chose our styrofoam recycling machine

Our EPE foam recycling line has been successfully adopted by clients in Bulgaria and Mexico, helping them turn bulky polyethylene foam waste—such as post-industrial EPE sheets used in packaging and cushioning—into reusable pellets. These projects solved common challenges in storage, transport, and environmental impact, and enabled our clients to build sustainable recycling businesses.

Read full case study:

- 250kg/h EPE Recycling Equipment Help Transform Foam Waste into Valuable Resources in Mexico

- Expanded Polyethylene Foam Recycling: A Successful Setup in Bulgaria

Spotlights of EPS foam granulating line

- Long service time and Stable operation

The machine is equipped with double reducer machines, so the machine could work stably and has a long service life.

- Multiple capacities for choice

Since the EPS foam granulator includes a crusher and an extruder, there is more output choice for customers.

- Tailor-made service

We provide customized service according to customers’ requirements about raw materials and capacities.

- Environment-friendly

The foam recycling line has low noise and pollution.

- Easy Operation and High Capacity

Application of foam particles

Packaging, insulated wall, billboard.

Hot Product

PET Plastic Bottle Recycling Machine

Our complete PET bottle recycling line is an…

Paraffin wax granule machine|Industrial paraffin pelletizer

The paraffin wax granule machine utilizes the low…

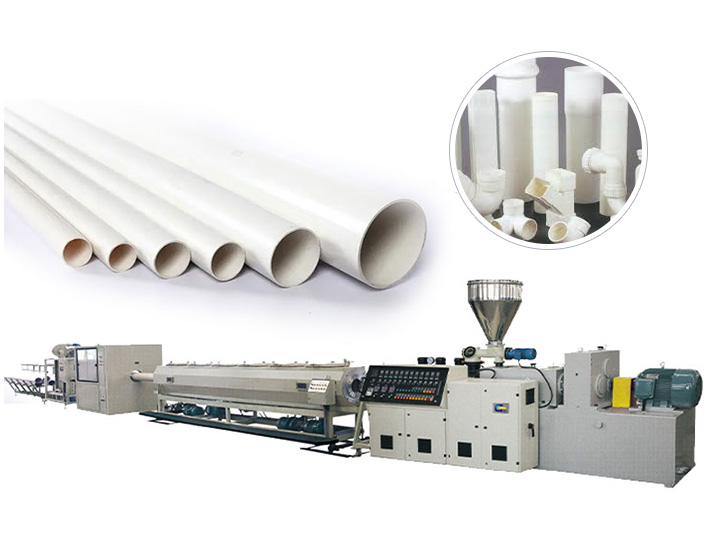

Plastic pipe making machine | PPR HDPE PVC pipe production line

Our company has a full range of plastic…

Turnkey OTR Tire Recycling Plant for Mining & Heavy Duty Tires

The disposal of Off-the-Road (OTR) tires presents a…

Tire Strip Cutting Machine for Efficient Tire Recycling

The processing of scrap tires requires reliable and…

Belt conveyor | Plastic bottle sorting table

Structure of belt conveyor The belt sorting table…

Plastic pellet storage bin | Recycled plastic granules silo

The plastic pellet storage bin is an alternative…

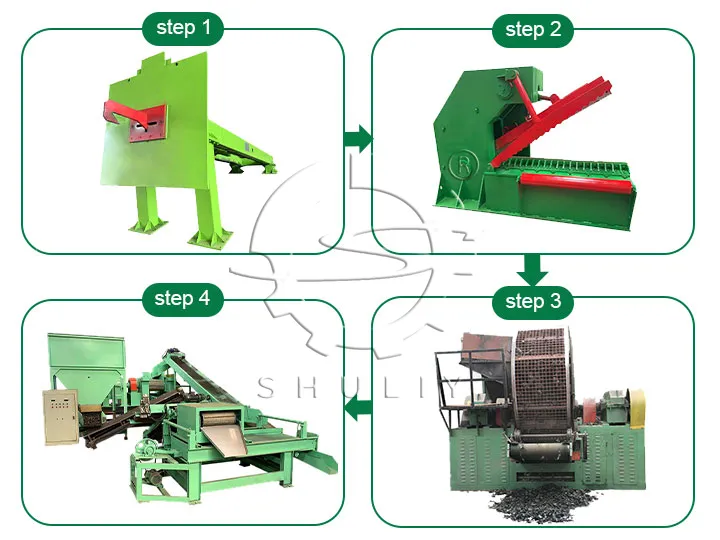

Waste tire recycling line | rubber granules making machine

The waste tire recycling line uses advanced tire…

Precision Rubber Block Cutter: Dual Models for Tire Recycling Lines

In a semi-automatic recycling line, the process of…