EPS Foam Granulating Line Sold to Romania

The EPE foam granulating line could recycle waste EPE package foam into granules. Romania is located in the northeastern part of the Balkan Peninsula in Southeast Europe. Romania has the highest economic growth rate among EU member states. In recent years, Romania’s economy has grown steadily, social and political stable, and its people live and work in peace and contentment. Romania has become an important emerging market in Europe.

Romania EPS foam granulating line case details

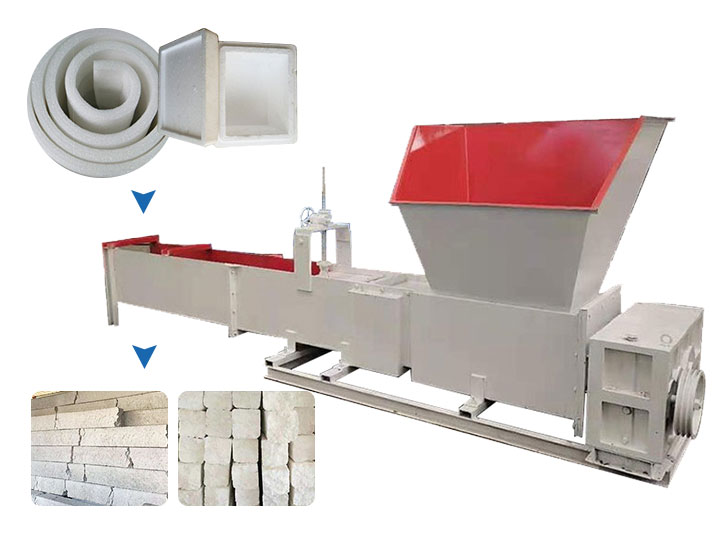

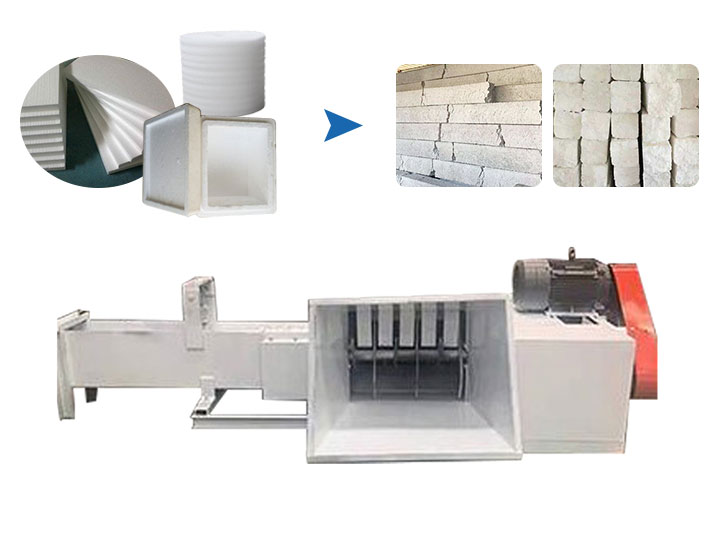

At the end of April, we received an inquiry from a Romania customer about the EPS foam granulating recycling production line. Because the EPS foam granulating line is suitable for recycling waste EPS foam package, EPS foam boxes, and other foam made of EPS. And we have an EPS foam granulating line and an EPE foam recycling production line. Therefore, we first inquired about the customer’s raw materials for processing. After learning that the customer’s raw material for recycling, we recommended the EPS foam granulating line to him.

Features of EPS foam granulating production line

- Double hardened gear reducers

This reducer could keep the machine working stably, and maintain a long service life.

- Multiple choices of mold heads

There are hydraulic double mold heads, round mold heads, electric double gear die heads, no net slag discharge die heads.

- Electromagnetic heating

Compared with using heating rings, electromagnetic heating is faster.

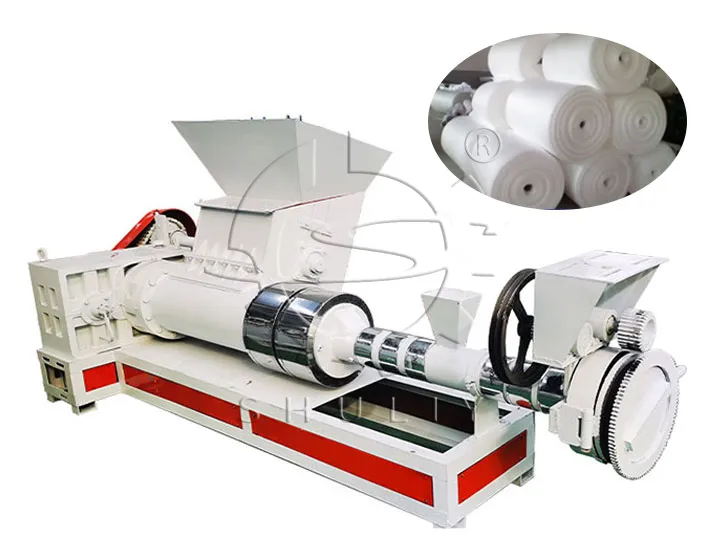

- Claw feeding

This kind of feeding hopper could avoid raw materials clogged, quickening the feeding speed.

claw feeding hopper

feeding

- Automatic operation

The foam granulator has complete supporting facilities, which can automatically and continuously produce, from raw material crushing, stretching to food particles.

- Wide application

The foam granulator is small, consumes less power, has a high quality of finished products, and has a wide range of applications.