Horizontal Styrofoam Shredder

Polystyrene Shredding Machines | EPS Foam Shredder

Horizontal Styrofoam Shredder

Polystyrene Shredding Machines | EPS Foam Shredder

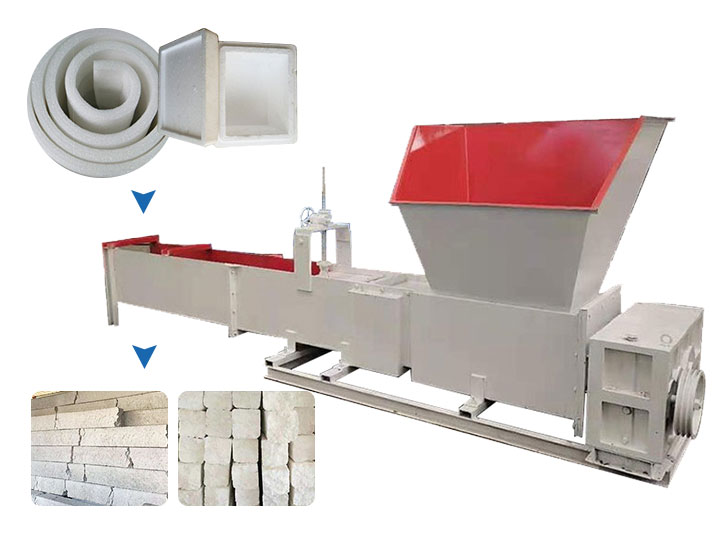

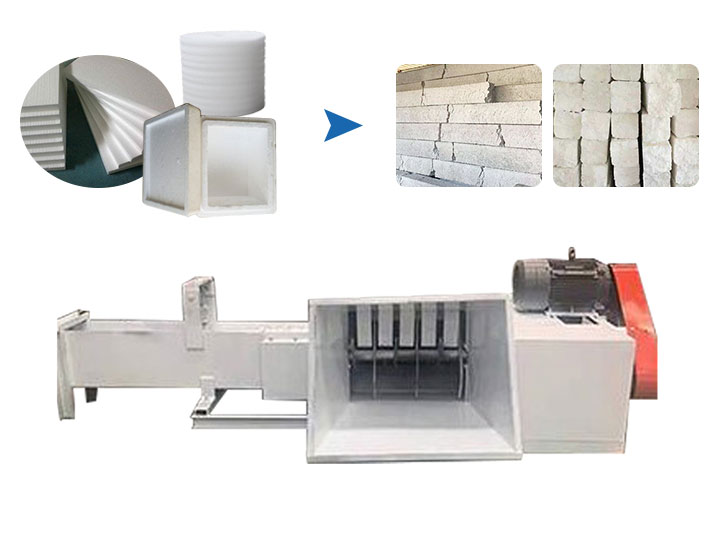

A horizontal styrofoam shredder is mainly used to crush waste foam products such as foam snack boxes, foam boxes, thermal insulation materials and foam materials into small pieces, and then blow the foam blocks into the polystyrene granulator for recycling and granulation while crushing. It greatly saves manpower and is an ideal EPS recycling machine.

The raw materials of the EPS recycling machine crusher

A horizontal styrofoam shredder is suitable for crushing all foam plastic products before granulating. Including disposable foam lunch boxes, eps expanded polystyrene styroboard, polystyrene eps foam packing sheets, foam insulation walls, foam packaging boxes, and fruit fresh-keeping nets. It is suitable for use in recycling plants of all sizes, greatly saving time and labor costs.

Features of the styrofoam shredder for sale

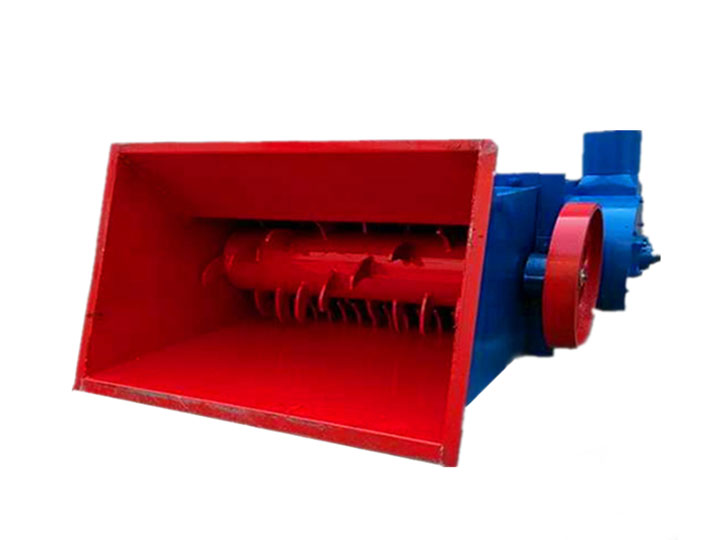

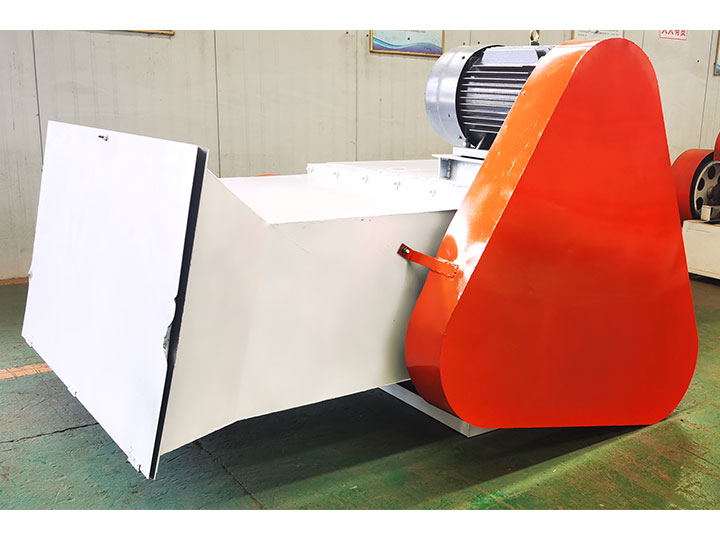

- This horizontal styrofoam shredder has the characteristics of large output, high efficiency, low dust, low noise, low energy consumption, convenient operation, low maintenance cost, etc., which can help users use the smallest production cost and create the largest profit.

- The feed inlet is flush with the ground,so operators can push the material directly in when feeding, saving labor costs.

- The shafts of the shredder are all solid shafts, which are more durable.

- The polystyrene shredding machines adopts a double dust removal system to make the crushed material cleaner.

- The blades of the polystyrene shredding machines all use CNC cutting machines, and the weight of each knife is the same, which has more advantages in power balance and greatly improves work efficiency.

Parameters of the eps foam shredder

| Type | Overall size (mm) | Size of the feed port (mm) | Power (KW) | Shredding Capacity (KG/H) |

| 800 | 1250*1290*660 | 800*600 | 5.5 | 250-300 |

| 1000 | 1250*1530*660 | 1000*600 | 5.5 | 300-350 |

| 1200 | 1300*1730*700 | 1200*600 | 7.5 | 400-450 |

| 1500 | 1600*2200*800 | 1500*800 | 11 | 450-500 |

Recommended polystyrene granulating line

The capacity of the complete polystyrene granulating line is 150-250kg/h.This set of foam recycling line produces automation and saves labor. In addition, the whole pelletizing line is compact and space-saving, suitable for small recycling plants.

Polystyrene shredding machines video

Hot Product

Vertical foam cutting machine

The Vertical foam cutting machine is dedicated to…

Plastic Bag Shredder Grinder Machine

A plastic bag shredder is a kind of…

Tire Sidewall Cutter Machine

The TCC-1250 tire sidewall cutter machine is a…

Waste Plastic Crusher for PP LDPE HDPE Recycling

A waste plastic crusher cuts plastic materials into…

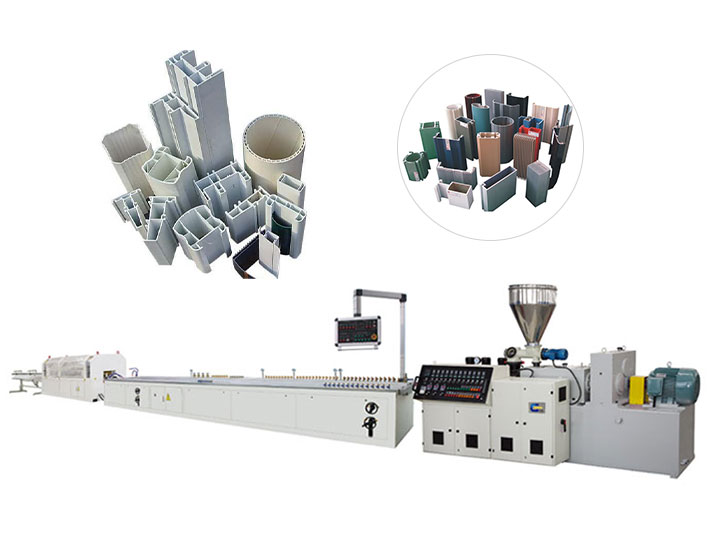

Plastic profile extrusion line | PVC ceiling making machine

Shuliy plastic profile extrustion line is a professional…

Vertical & Horizontal Plastic Baler Machine for Bottles Bags Cardboard & More

The commercial plastic baler is mainly used for…

Horizontal EPS Foam Compactor

The function of the horizontal EPS foam compactor…

Belt conveyor | Plastic bottle sorting table

Structure of belt conveyor The belt sorting table…

Waste tire recycling line | rubber granules making machine

The waste tire recycling line uses advanced tire…