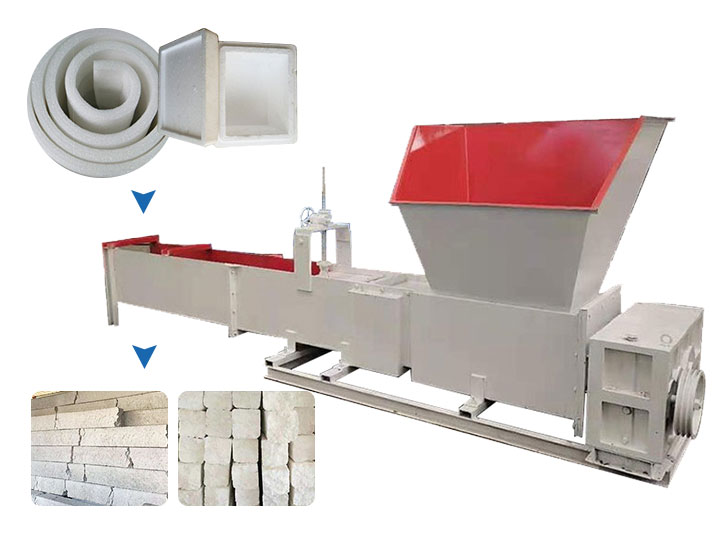

Horizontal EPS Foam Compactor

Styrofoam compactor | EPS recycling machine

Horizontal EPS Foam Compactor

Styrofoam compactor | EPS recycling machine

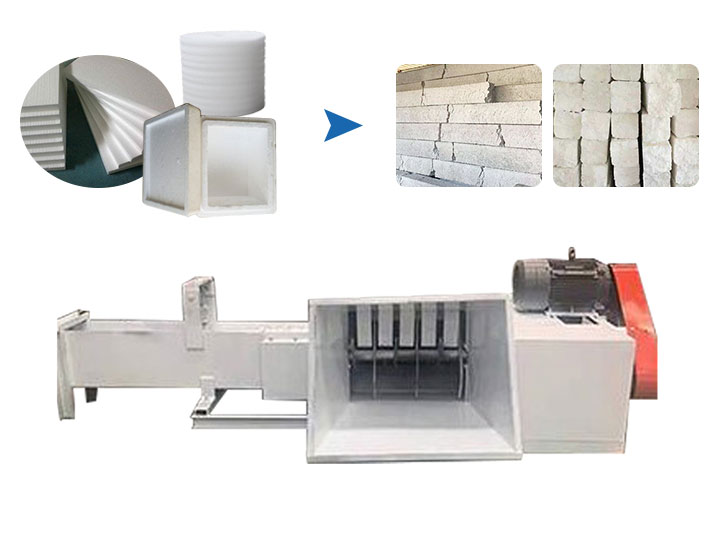

The function of the horizontal EPS foam compactor is the same as that of the vertical cold press, which squeezes and shrinks the large volume of foam and provides convenience for transportation. However, its inlet is parallel to the ground, which saves a lot of effort for the staff. After the EPS/EPE foam is compressed by the foam cold compactor, the foam density increases and becomes a square block, which is convenient for transportation and storage. The EPS foam densifier has the features of reasonable design, high degree of automation, efficient process, energy-saving, and pollution-free. Horizontal EPS foam compactor is suitable for squeezing various kinds of products made of EPE/EPS foamed plastics, such as fast food boxes, cake boxes, foam packaging materials, thermal insulation materials and foam materials, and other waste plastic products.

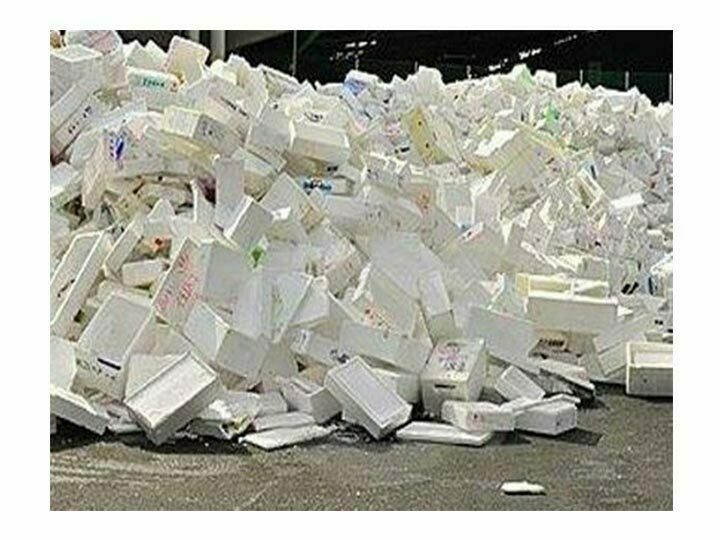

Why need a EPS cold compactor?

Plastic foam packaging is widely used in life. This kind of foam will produce white pollution if discarded randomly. Traditional treatment methods such as burning produce a lot of smoke and pollute the air, and landfilling will not degrade the foam. Reasonable recycling of foam plastic is very necessary. The EPS cold press machine can compress the waste foam for reuse without pollution.

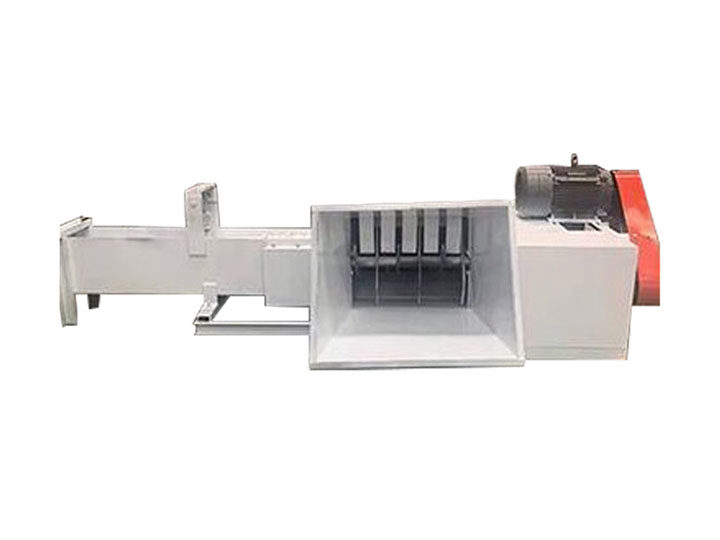

Introduction of the horizontal EPS foam compactor

A horizontal foam compactor is a machine improved on the basis of the vertical foam compactor. The inlet is flush with the ground. When feeding, you can directly use the broom to sweep into the inlet, which is very similar to the horizontal foam crusher.

Horizontal EPS foam compactor advantages

- This compactor is equipped with a separate pre-crushing device, and large pieces of foam can be crushed directly.

- The inlet is flush with the ground, and the foam plastic can be pushed into the inlet directly with the broom when feeding.

- The feed opening is widened, realizing the concept of time-saving, labor-saving, high-efficiency and energy-saving.

- The processed foam is non-toxic, odorless, and environmentally friendly. Foam foam densifier machine can directly pushes EPS/EPE foam without heating.

- The compression ratio is large, and the volume can be reduced by 40 times, saving storage space, convenient transportation and saving storage costs.

Parameters of the foam compactor

| Type | Machine size (mm) | Inlet size (mm) | Power (KW) | Capacity (KG/H) |

| SL-300 | 3000*1700*900 | 830*760 | 15 | 175 |

| SL-400 | 4600*2800*1200 | 870*860 | 22 | 300 |

We offer many types of horizontal EPS foam compactors. The above are the common types of machines. The capacity differs in size and power. For customers’ special needs, we can customize the machine accordingly.

Hot Product

Vertical EPS foam compactor | Styrofoam recycling densifier

Vertical EPS foam compactor is one of the…

Fibre Shearing Machine | Fiber Shredder for Cutting Waste Cloth

The fibre shearing machine can cut worn-out clothes…

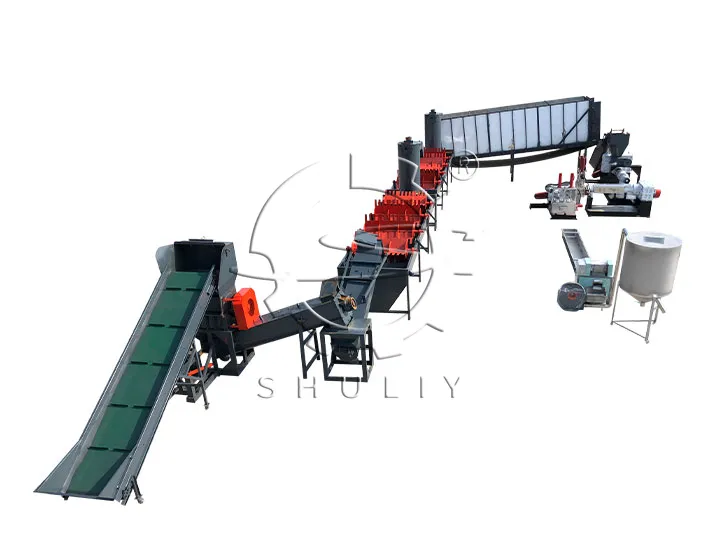

Plastic Film Granulator for PP PE LDPE LLDPE Recycle

The plastic film granulator by Shuliy is a…

Plastic Pellet Making machine

A plastic pellet making machine is a recycling…

PET Bottle Washing Plant Machinery

Our PET bottle washing plant is a suitable…

Rigid plastic recycling lines for HDPE PP

The plastic recycling lines for HDPE PP and…

Tire Sidewall Cutter Machine

The TCC-1250 tire sidewall cutter machine is a…

PP PE Plastic Crushing and Washing Machine

The plastic crushing and washing machine is mainly…

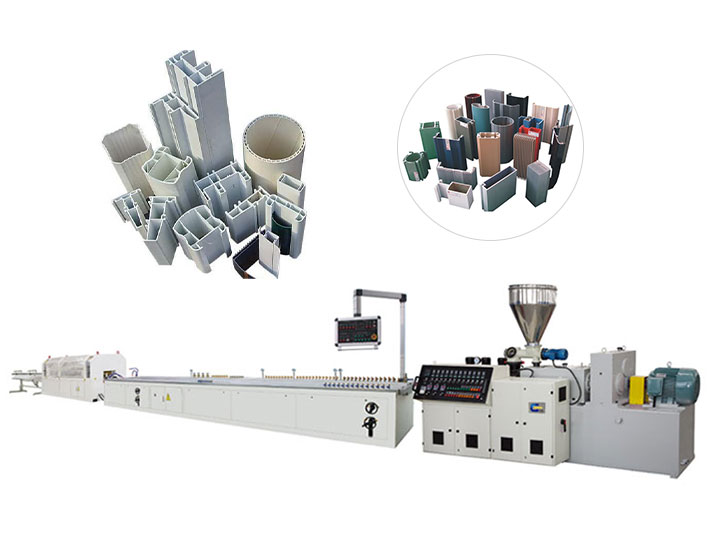

Plastic profile extrusion line | PVC ceiling making machine

Shuliy plastic profile extrustion line is a professional…