Rigid plastic recycling lines for HDPE PP

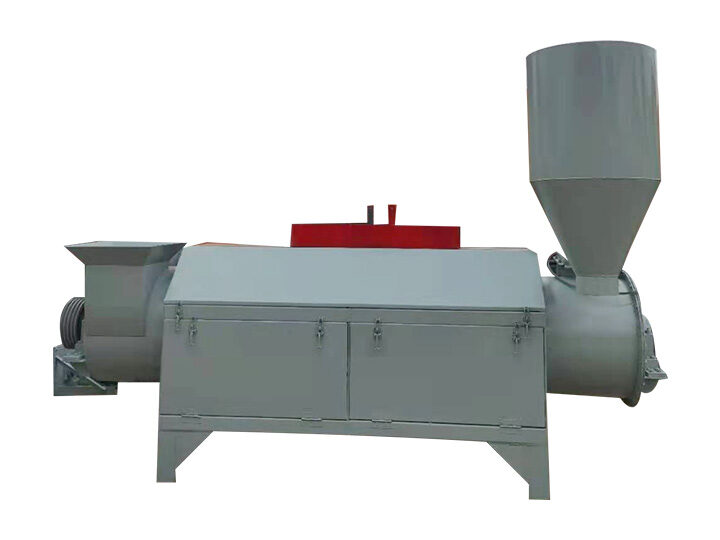

Plastic pelletizing machine | Hard plastic granulating line | Plastic pellet production line

Rigid plastic recycling lines for HDPE PP

Plastic pelletizing machine | Hard plastic granulating line | Plastic pellet production line

Our plastic recycling lines offer a quick and efficient solution for rigid plastic waste. This rigid plastic recycling line is used to reprocess Polyethylene (HDPE) and Polypropylene (PP) waste plastics.

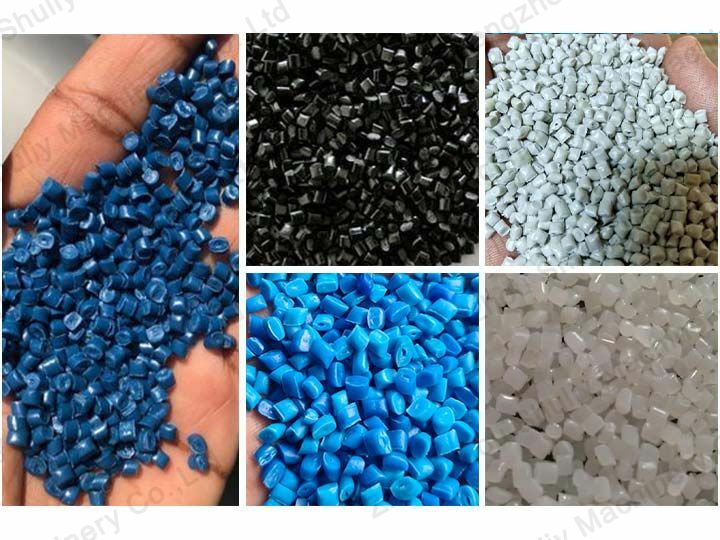

For example, HDPE bottles, PP pipes, toys, etc. Those plastics will be crushed, washed and pelletized by a series of efficient recycling machinery. The end products you will obtain are fully cleaned recycled plastic pellets, that can be reused in manufacturing.

Shuliy Group can match different recycling lines for plastic recycling plants of different scales. We design factories, and calculate factory areas according to customers’ different production needs, uses, and raw materials. The standard capacity of the pelletizing line is 100-500kg/h, we also provide larger output for special pelletizing demands.

Applicable raw materials and final products

The plastic pelletizing line is specially designed for recycling hard plastic, such as plastic drums, plastic boxes, toy scraps, cosmetic tubes, electronic meters, automotive part waste, car bumpers, pipes, chemical drums, food containers, regrind plastic, plastic waste from injection and extrusion and so on. The plastic pelletizing machine will extrude the plastic waste into small pellets, they can be processed in plastic production lines, like plastic pipe production.

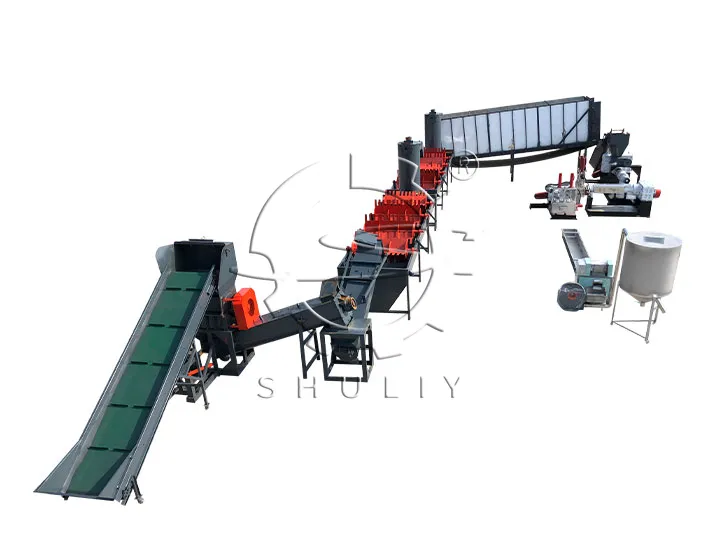

Plastic recycling lines working process

It is also possible to configure exhaust gas purification devices, storage bins, bagging machines, and other related equipment according to customer needs. Through the above steps, the waste plastics are recycled for reprocessing. The entire plastic granulating line from waste to finished products is easy to operate, with high efficiency, environmentally friendly, and energy-saving.

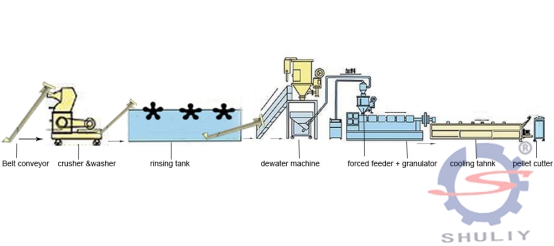

Plastic recycling lines workflow

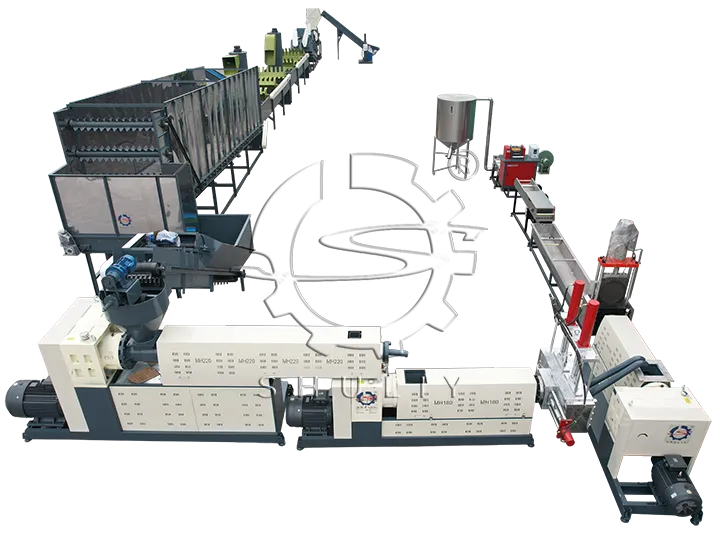

The plastic recycling lines mainly consist of a conveyor belt-crushing machine- rinsing tank – dewatering machine – conveyor – plastic pelletizing machine – cooling tank – pelletizer and other components.

Machines for plastic recycling plant

Belt Conveyor: In the plastic recycling lines, the conveyors are used to send PP PE materials to the crusher machine.

Crusher: Crush PP, and PE material into small pieces

The waste plastic crusher is used for crushing the PP/PP material to small pieces in the plastic pelletizing line , it has the characteristics of low speed, low noise, and no slag material.

At the same time, wet pulverization not only enhance the water cleaning effect of plastic chips, but also reduce the friction heat due to the cooling effect of water, prolonging the service life of the blade, low maintenance cost, long service life, therefore, so this type plastic crusher has received unanimous praise from customers

Rinsing tank: Rinse the crushed PP, PE

The rinsing tank is used for rinsing the broken material to precipitate impurities.

It is made of stainless steel or an iron plate. There are many many toothed plates in the tank, it can force plastic chips to move forward and shift the material in the pool from this end to the other end of the pool.

Drying machine: Remove the water from PP, PE pieces.

A horizontal dewatering machine is specially used for cleaning and dewatering waste plastic flakes and granules in the plastic pelletizing line.

The high degree of dehydration, dehydration rate of over 97%, low power consumption, high efficiency, high degree of automation, and greatly reduced labor intensity

Plastic pelletizing machine: Heat and melt the PP, PE pieces, then extrude them with strip shape.

Waste plastic granulation extruder is a device for extruding, cooling, and dicing polyethylene (green film, lining bag, etc.) or polypropylene (old woven bag, packing bag, tying rope, etc.) to produce plastic granules. The granules produced are widely used and are ideal for PP PE plastic recycling.

This plastic granulation equipment is matched with the crushing and cleaning machine and the pelletizer. Broken and cleaned plastic can be directly put into extrusion granulation.

Cooling tank: Cool the soft strip plastic.

Cooling the soft strip plastic extruded from the plastic pelletizing machine, making them hard then cutting them into pellets.

It is made of stainless steel, also, you can choose iron type, just choose it according to your demands.

Pellet cutter: Cut the hard strip plastic to the pellet after a plastic recycling pelletizing machine .

This pellet cutting machine has superior performance and reasonable structure. The sealing performance of the whole machine is better. It is convenient to adjust the cutting distance.

The rotary cutter is made of a hard alloy hob, its wear resistance is extremely high, and the whole machine without gear design effectively reduces the machine noise with the belt rotation. and the independent electrical box is convenient, safe, and beautiful. Cold-drawn pelletizing for various high-yield, high-strength engineering plastics.

Storage bin: The storage bin is made of stainless steel, and the stock bucket and the wind-feeding material are combined into one, occupying less land and saving labor.

It can be docked with various granulators for easy movement. The fan power is small, the feeding speed is fast, saving cost. The storage bucket size is customized according to customer requirements, and the size is optional.

3D video of PP PE plastic pelletizing line

What is the difference between PE and PP plastic?

There is no doubt that modern society is very dependent on plastic products. From product packaging and common household items to automobiles and industrial facilities. In the field of plastics used for consumer goods, two types are far more popular than others: polypropylene (PP) and polyethylene (PE). Then, there is a question: what is the difference between PE and PP plastic?

Working principle of plastic pelletizing machine

This plastic recycling pelletizer machine is developed through the introduction, digestion, and absorption of advanced concepts and technologies at home and abroad, combined with the needs of today’s development and the characteristics of recycling waste plastics. It can meet the environmental protection requirements for the recycling of waste plastics at home and abroad. Handle hard plastics such as discarded plastic baskets and barrels.

Methods for plastic pelletizing machines do not discharge

In the process of using the plastic pelletizing machine, the problem of non-discharge is prone to occur, there are some following suggestions:

- The causes of the low lubricating oil pressure are listed as follows. The pressure setting value of the pressure regulating valve of the lubricating oil system is too low, the oil pump is faulty or the oil suction pipe is blocked. The solution is to check and adjust the pressure regulating valve of the lubricating oil system and then check the oil.

2. The rotation speed of the main motor of the plastic recycling pelletizing machine is not uniform, the rotation speed of the feeding motor is not uniform, and the feeding amount fluctuates. The treatment method is to check the main motor control system and bearings.

3. If there is no problem with the plastic pelletizing machine, you can check is there any iron or other things like a large piece of hard material that has been introduced, and affect the normal operation of the plastic recycling pelletizing machine.

Plastic pellet cutter in the plastic recycling plant

Our company has two different kinds of plastic pellet cutter, one is hob pellet cutter, and the other is simple pellet cutter. We can offer different pellet cutters according to the customers’ orders. The hob pellet cutter is the most commonly used, the basic parameter is as follows:

Model: LY-F220

Power: 2.2kw

Capacity: 300kg/h

Size: 800*550*1150mm

The cost of these two kinds of pellet cutter has some differences, welcome to consult,we will give you a satisfactory answer.

Specification for our plastic recycling lines

This plastic recycling lines can be combined into various specifications according to customer requirements. From 200KG/H-3000KG/H, our company has had successful cases. The plastic pelletizing machine has a beautiful appearance, low energy consumption, high output, practicality, and reliability. The new rinsing device can be used for washing, greatly improving the production efficiency, and the cleanness of the washing material is pure, reaching the requirements of the first-level net film. It is an efficient, water-saving device.

Our company is engaged in waste plastic recycling pelletizing machine for more than 10 years, can design different cleaning plans, cleaning processes, recycling planning, and site planning according to your different requirements. With our expertise, you will be rewarded with a good return on your investment.

Successful cases of plastic recycling lines

HDPE plastic recycling line in Oman

One client from Oman chose Shuliy plastic recycle machines for his new project. Our technical staff went to his factory and assisted him in installing the machines. Know more details on this page: Oman HDPE plastic recycling project

HDPE pelletizing line in Nigeria

The Nigerian customer made two orders from us, one is machine for recycling PET bottles, and the other is for HDPE plastics, both are successful cases. Now the machines already run. More details you can check on: HDPE pelletizing line in Nigeria

Plastic pelletizing line sent to Ghana

A customer in Ghana has chosen our plastic recycling plant and has shipped a set of plastic granulation equipment and cutter to Ghana. The customer in Ghana saw our machines on the website and approached the sales manager for advice. They wanted to use the machine to recycle the local waste plastic film, after which the recycled plastic pellets will be used to make new plastic products. Nowadays, recycling machines have been shipped to Ghana already.

Plastic recycling line machinery sent to Saudi Arabia

Our customer from Saudi Arabia bought a complete recycling line from Shuliy this July, the capacity is 1 t/h, the plastic granulation equipment will be used in his plastic recycling plant.

HDPE plastic recycling pelletizing machine working smoothly in Mozambique

This is a successful case from Mozambique. The customer from Mozambique sent us their HDPE plastic recycling pelletizer machine bought from Shuliy, they expressed their satisfaction of the granulator and its final pellets.

Why choose Shuliy recycling machines?

Our company is a manufacturer specializing in plastic recycling lines machinery. We own the complete lines of waste PE PP products, we have many years of experience in the recycling of waste resources, adhering to the “innovative and enterprising, excellence” corporate philosophy, cultivated in the environmentally friendly recycling machinery industry. The plastic recycling pelletizer machine has served as a major part of markets of countries and regions.

Sales service of plastic recycling lines

Pre-sales service: Provide you with project planning; process design; develop a set of recycling machinery that suits you; design and manufacture products according to your special needs, and provide training for your technical operation;

In-sale service: Precise production equipment, and accompany our customer to complete the acceptance of the plastic recycling pelletizer machine, assist in the preparation of the installation plan and detailed process;

After-sales service: our company will send technicians to customers’ sites to guide the installation of plastic recycling pelletizer machine, commissioning the recycling machinery to normal production and training the operators for use and maintenance;

Product quality: Except for wearing parts, quality assurance within one year, lifetime maintenance.

Our company’s integrity management, and quality assurance, welcome all types of plastic recycling plants to consult and negotiate.

Hot Product

Frictional washing machine for PET bottle recycling

Working process of the frictional washing machine As…

Cotton Waste Recycling Machine | Garment Rags Tearing Machine

The cotton waste recycling machine is mainly used…

Pioneering waste plastic water ring pelletizer

Due to the advantages of the water ring…

Plastic pellet dehydrator

The plastic pellet dehydrator is used to remove…

Plastic Bag Shredder Grinder Machine

A plastic bag shredder is a kind of…

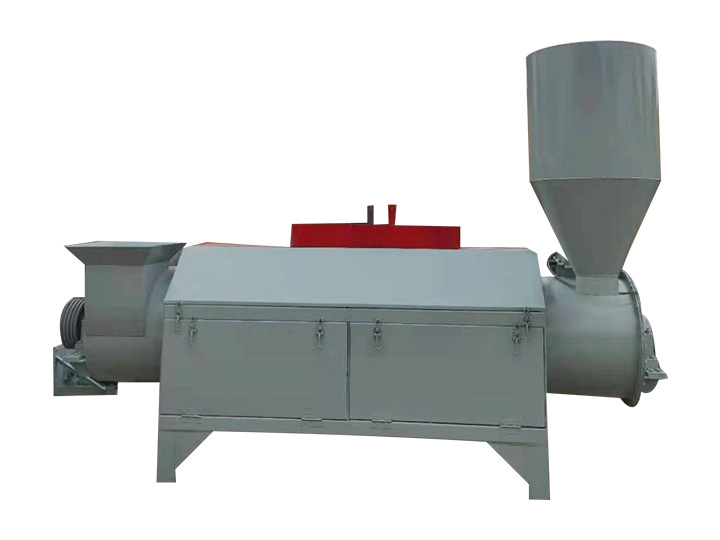

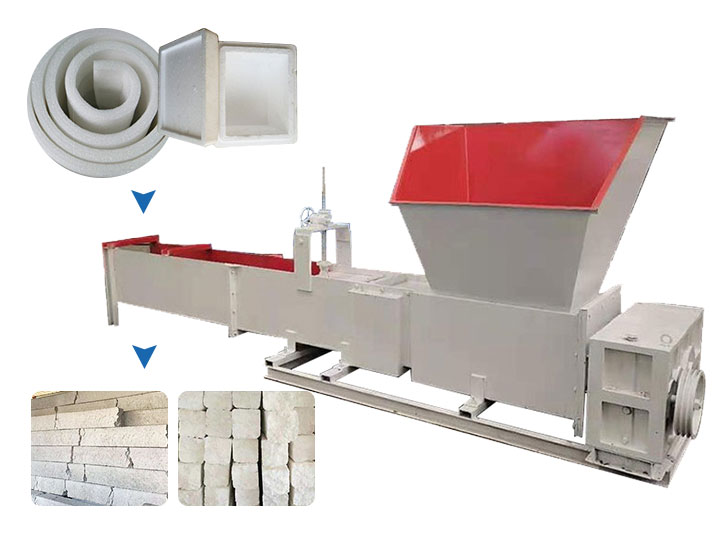

Vertical EPS foam compactor | styrofoam recycling densifier

Vertical EPS foam compactor is one of the…

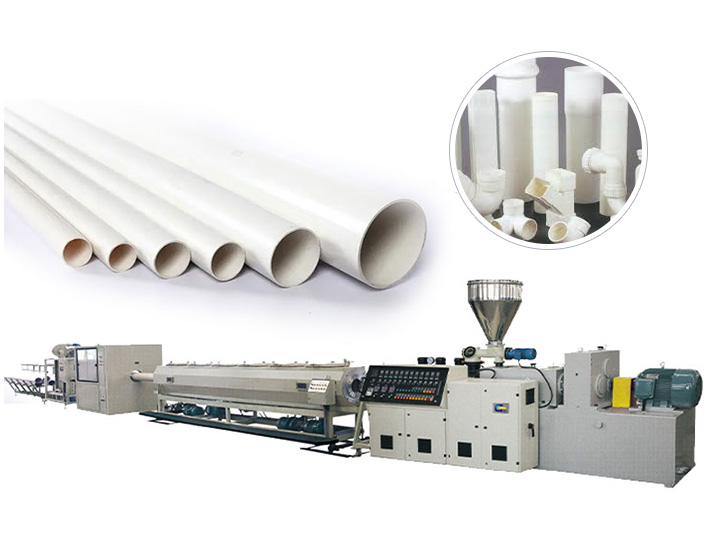

Plastic pipe making machine | PPR HDPE PVC pipe production line

Our company has a full range of plastic…

Vertical & Horizontal Plastic Baler Machine for Bottles Bags Cardboard & More

The commercial plastic baler is mainly used for…

Plastic film cold washing rinsing tank

The rinsing tank is used for rinsing the…