Pioneering waste plastic water ring pelletizer

In the waste plastics granulation process, there are two most commonly used pelletizing methods. One is to cool the extruded plastic strips in a water tank and then cut them into pellets with the roller cutters of the plastic pelleting cutting machine; the other is to use a water ring die face cutter. Due to the advantages of the water ring pelletizer system, water ring pelletizer is more and more favored by practitioners in the plastic recycling and processing industry. The plastic pellets cut out by the die face cutter machine are round, uniform, and beautiful in appearance. Also, the water ring pelletizing system saves site area and labor cost and makes has less waste compared with traditional pellet cutter machines.

What is PP PE plastic water ring pelletizer?

Plastic water ring pelletizing machine is a kind of equipment used in the plastic pellet production line, suitable for pelletizing most thermoplastics. The die face pelletizing system is that the waste PP plastics or PE plastics are cut into granules as soon as it comes out of the die surface. Since plastic material is cut into pellets while in hot temperature, die face cutter plant is also a form of eager cutting. The plastic granules produced are thrown into the high-speed rotating water flow, and then sent to the dehydration equipment.

Read more:

- PP HDPE LDPE film granules making machine

- Plastic film bag pelletizing recycling line

- Granulating line for rigid plastic scraps

Applicable materials

The die face plastic cutting machine is suitable for PP film, PP woven bag, PP ton bag material, PE film, PP/PE crushed material.

Why need a water ring pelletizer system in plastic recycling line?

- Smooth and uniform plastic pellets. The die face cutting recycling machine adopts the hot-cut water-cooling method, and the plastic granules are smooth and round, in uniform shapes without pores. Uniform particles bring a lot of convenience to the quality of production and processing of subsequent products and the control of cost and expense;

- Adjustable granules sizes. Since the motor of die face cutter extruder adopts frequency conversion speed regulation, the pelletizing speed can be adjusted, so the particle size can be adjusted by adjusting the speed of the cutter to meet customer requirements.

- Space-saving. In the use of the water ring pelletizer, it does not need a cooling water tank as used in traditional cutting process, so the floor area is small, which saves space.

- Continuous operation and labor-saving. The water ring pelletizing system is usually used in conjunction with the quick screen changer. There is no problem of broken strips when changing the screen, and it does not affect the subsequent pelletizing, so the generation of waste and the labor cost of workers is also reduced.

- Easy operation and low operaton cost. The water ring die face cutter has a compact design, low operating cost and simple start-up procedure.

- High production efficiency. The water ring die face cutter has various output for options, 100-1000kg/h.

Composition of the water ring pelletizing machine

The water ring pelletizer mainly includes a water ring pelletizing die, pelletizing system, water ring pelletizing cover, heater, water pump, frequency converter, circulating cooling pool. The machine can be used with a dehydrator. The die head is made of die steel, and the others are made of stainless steel. Various water ring pelletizing systems can be customized according to customer requirements.

Video of die face cutting recycling machine

Water ring pelletizer operation process

The long strips extruded from the discharge die head of the plastic extruder are cut by the rotating cutter head immediately after exiting the die. The plastic beads are thrown to the inner cavity attached to the pelletizing cover for high-speed operation and got initially cooled by water. Then the water flow sends the plastic pellets to the drying machine and then sent to the material cooling equipment. Thus, the plastic granules are finished.

The water used for cooling and transportation in the water ring pelletizing system does not come into contact with the die head. Due to the formation of a water ring around the die, the die is not in contact with the cooling water. This feature ensures the uniformity of the die temperature so that even if the output is low, the discharge of the die head is still normal. The rotating cutter cuts the molten strands and throws the hot molten particles into the circulating water under the action of centrifugal force. The water flow carries the particles out of the pelletizing hood.

Hot Product

Rigid Plastic Shredder Machine

Shuliy rigid plastic shredder machine is also called…

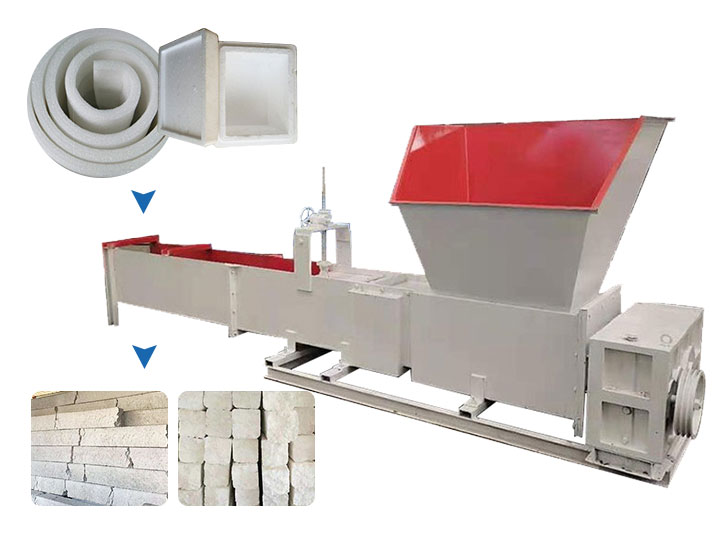

Vertical foam cutting machine

The Vertical foam cutting machine is dedicated to…

Plastic Pelletizing Machine

The plastic film pelletizing machine can also be…

Belt climbing conveyor | Inclined transport machine

A belt climbing conveyor is an essential machine…

Plastic Sink Float Separation Washing Tank

Our plastic sink float separation washing tank uses…

Waste tire recycling line | rubber granules making machine

The waste tire recycling line uses advanced tire…

Vertical EPS foam compactor | Styrofoam recycling densifier

Vertical EPS foam compactor is one of the…

EPE Recycling Machine for Foam Pelletizing

Waste EPE foam pelletizing machine is suitable for…

Plastic pellet storage bin | Recycled plastic granules silo

The plastic pellet storage bin is an alternative…