Plastic film cold washing rinsing tank

PP PE plastic washing tank | Plastic washing machine

Plastic film cold washing rinsing tank

PP PE plastic washing tank | Plastic washing machine

The rinsing tank is used for rinsing the broken material to precipitate impurities in the plastic recycling line. It is made of stainless steel or an iron plate. There are many toothed plates in the tank, which can force plastic chips to move forward and shift the material in the pool from this end to the other end of the pool.

Applications of the PP PE plastic rinsing tank

After crushing the waste plastic products with the plastic crushing machine, the plastic waste is still dirty, so it is very necessary to send them into a plastic cleaning tank. The toothed plates will force the plastic material again and again when they arrive at the other side of the tank. This plastic washing equipment will clean the plastic entirely. For some plastic recycling plants, the cleaned plastic pieces will be process further in a granulator,the final granules are popular in the global market.

Structures of the PP PE plastic washing tank

This equipment is made from stainless steel or steel, customers can choose different materials according to their orders.

The stirring wheels in the tank are very important, they will send the plastic pieces from one side to the other side, and at the same time, the dirty plastics will become clean.

PP PE plastic washing rinsing tank video

Self-built washing tank

The washing tank is usually very large, so it is different to transport by ship. Therefore, we suggest our customers make water tanks by themselves, the length is about 15-20 meters, the distance of each two stirring wheels is 1.5-2 meters. You can consult our operators if you have any questions during building the washing tank.

Parameters of plastic film cold washing rinsing tank

For nominal capacity of plastic pelletizing like 100-500kg/h, the rinsing tank of following model is enough. However, if your pelletizing capacity is large like 600-1000kg/h, Shuliy Group will recommend you to choose a longer tank your washing your raw materials, such as thirty meters long.

| Model | SL-150 |

| Tank length | 15-20m |

| Qty of rotating wheel | 10 |

| Distance between every two wheels | 1.5-2m |

Recommended plastic vertical lifting dewatering machine

The function of a vertical plastic lifting dewatering machine is to lift and remove moisture from plastic materials. This is an important step in the plastic recycling process, as it helps to reduce labor costs and improve the efficiency of the recycling line.

The vertical lifting design of the machine allows for better drainage and more effective dewatering compared to other types of machines. It also helps to prevent blockages and ensure a smooth and efficient operation.

Hot Product

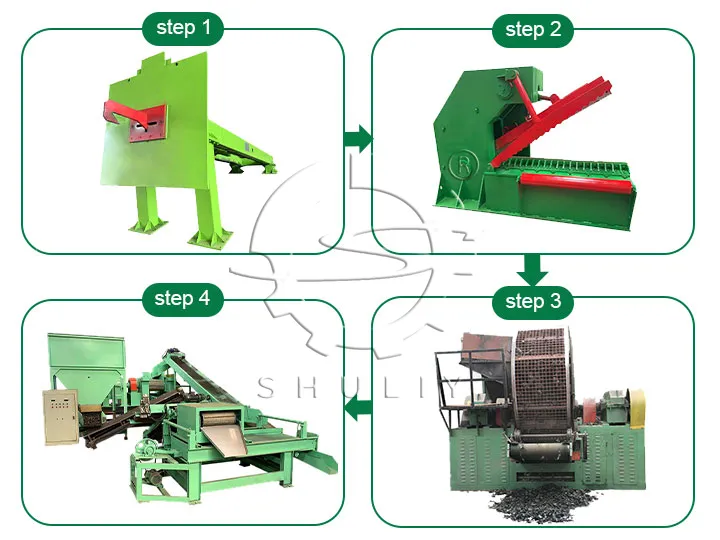

Precision Rubber Block Cutter: Dual Models for Tire Recycling Lines

In a semi-automatic recycling line, the process of…

Electrostatic spray machine | Manual powder coating gun

The electrostatic spray machine is industrial equipment for…

Automatic feeding machine | Forced feeder for plastic recycling

This automatic feeding machine is designed to simulate…

Tire Strip Cutting Machine for Efficient Tire Recycling

The processing of scrap tires requires reliable and…

Plastic pellet dehydrator

The plastic pellet dehydrator is used to remove…

Turnkey OTR Tire Recycling Plant for Mining & Heavy Duty Tires

The disposal of Off-the-Road (OTR) tires presents a…

Rubber powder production line | waste tire recycling plant

The rubber powder processing line is specialized for…

Plastic Pellet Making machine

A plastic pellet making machine is a recycling…

Rigid Plastic Shredder Machine

Shuliy rigid plastic shredder machine is also called…