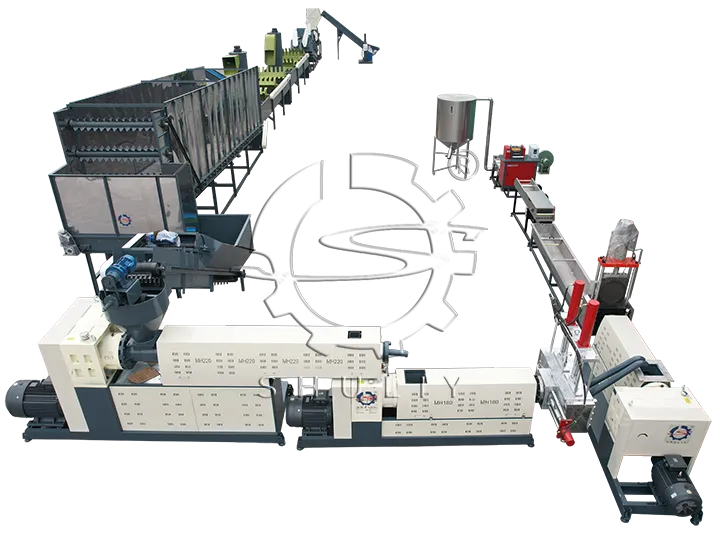

Cooling tank | Pellet cooling machine

The plastic cooling tank is a very important part of the plastic pellets production line. The cooling temperature has a very large effect on the quality of the plastic pellets. It is a necessary machine in the recycling line. If you want to process the waste plastic into plastic pellets, our cooling tanks can help you make high-quality plastic pellets more efficiently.

Usage of cooling tank

The plastic strips extruded by the granulator are very soft and hot, so they can not be cut into small pellets yet. Cooling the soft strips of plastic and making them much harder is a very important step during the whole recycling line. Then the plastic pellet cutting machine will cut them into pellets.

The material of cooling tank

It is made of stainless steel, the stainless steel will not rust and has a long use time, so it is the best choise for customers. Also, you can choose the iron type, just choose it according to your demands.

Parameters of cooling tank

| Name | Length | Width | Material |

| Cooling tank | 2.5m | 0.4m | Stainless steel |

Hot Product

Plastic Film Recycling Machine

The plastic film recycling machine is highly efficient…

EPS/Styrofoam Densifier Hot Melting Machine

Descriptions of the styrofoam densifier The styrofoam densifier…

Plastic Pelletizing Machine

The plastic film pelletizing machine can also be…

EPE EPS Foam Granulating Line

The EPS foam granulating line is suitable for…

Plastic pellet storage bin | Recycled plastic granules silo

The plastic pellet storage bin is an alternative…

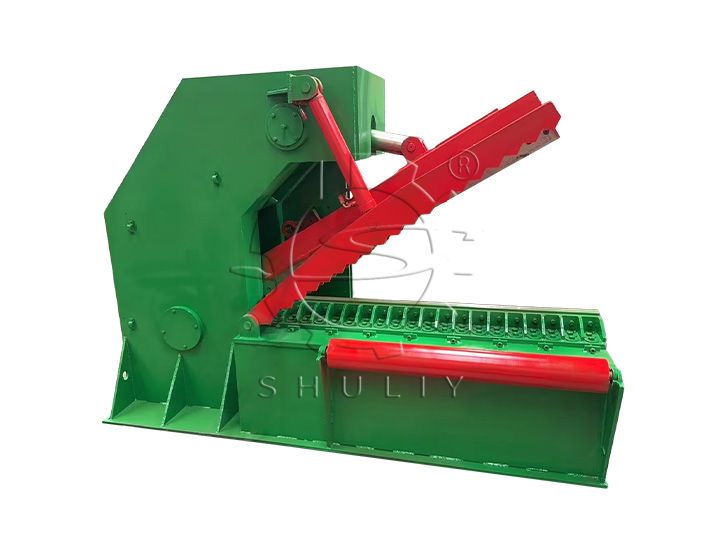

Tire Strip Cutting Machine for Efficient Tire Recycling

The processing of scrap tires requires reliable and…

Frictional washing machine for PET bottle recycling

Working process of the frictional washing machine As…

OTR Tire Cutting Machine for 1400-4000mm Tires

The OTC-4000 is a specialized OTR tire cutting…

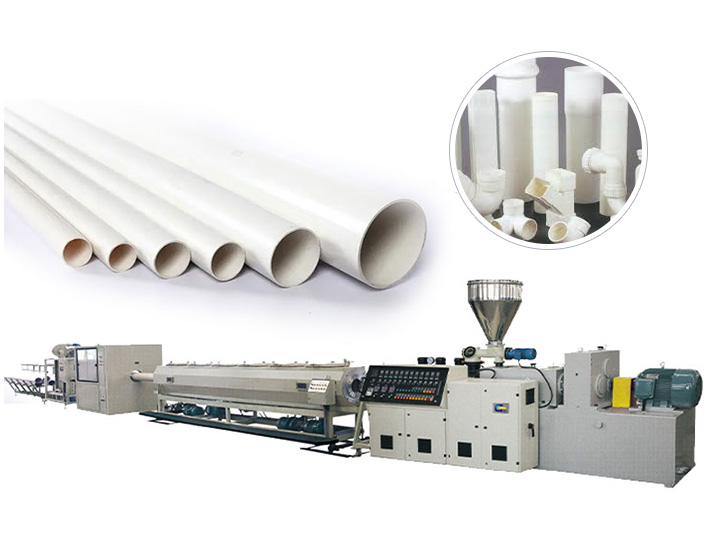

Plastic pipe making machine | PPR HDPE PVC pipe production line

Our company has a full range of plastic…