Waste Gas Filter | Plastic Recycling Filtration System

Pure water-flue gas treatment is a modern standard environmental waste gas treatment equipment. The waste gas filter uses environmentally-friendly natural pure water for exhaust gas purification, in order to achieve the purification of odorous gases, such as exhaust gas, and smoke. The waste gas filter is smokeless and tasteless, achieving the true meaning of environmental purification.

Description of waste gas filter :

Most of the waste gas produced by the recycled plastic pellet machine is volatile organic waste gas and malodorous gas. The waste gas contains toxic substances and has an obvious peculiar smell. A plastic recycling filtration system,also known as an air purifier, is the special equipment for purifying soot and waste gas during produce plastic products. A waste gas filter is an important machine in the plastic pelletizing processing line. This machine can reduce the damage to the surrounding environment during plastic processing.

Application of gas filter

Before starting plastic waste recycling, manufacturers should firstly consider the pollution in the recycling process. They should have clear sewage treatment facilities based on sewage conditions, and then discharge them in accordance with national wastewater discharge standards. The gas filter mainly used in the air purification of plastic pellets, plastic products, and various plastic processing industries.

Advantages of waste gas filter

- The equipment is made of full stainless steel, so it will never rust and has a long service life.

- It can be used directly without any external power during use, so it can save time and cost.

- The treated soot rate is as high as over 95% and can reach environmental standards.

Parameter of gas filter

| Model | 01 |

| Weight | 200kg |

| Dimension | 300*800*2200mm |

Hot Product

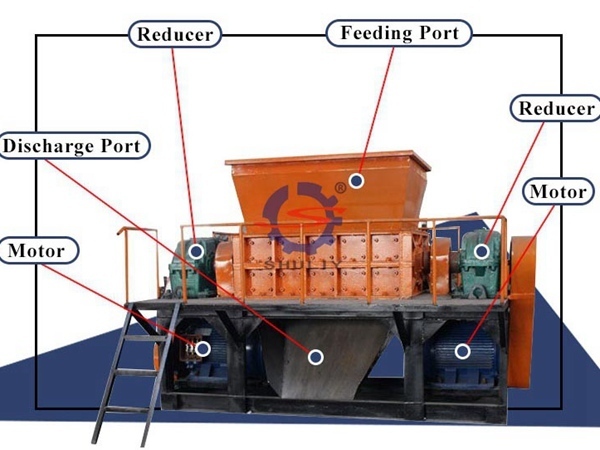

Rigid Plastic Shredder Machine

Shuliy rigid plastic shredder machine is also called…

Paraffin wax granule machine|Industrial paraffin pelletizer

The paraffin wax granule machine utilizes the low…

Belt conveyor | Plastic bottle sorting table

Structure of belt conveyor The belt sorting table…

EPS Granulator | Expanded Polystyrene Foam Recycling Machine

EPS granulator is mainly suitable for foam fast…

Plastic pellet bagging machine | Packing machine

Waste plastic needs to be packaged completely after being processed…

Waste Plastic Crusher for PP LDPE HDPE Recycling

A waste plastic crusher cuts plastic materials into…

Plastic shredder machine for metal tire shredding

The plastic shredder machine mainly uses the principle…

PET Bottle Crushing Machine

PET bottle crushing machine plays a very important…

Cooling tank | Pellet cooling machine

The plastic cooling tank is a very important…