EPS Granulator | Expanded Polystyrene Foam Recycling Machine

EPS Granulator | Expanded Polystyrene Foam Recycling Machine

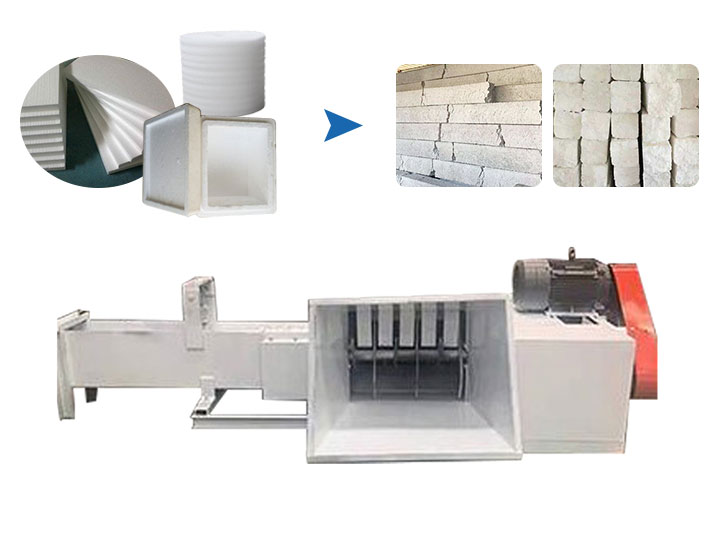

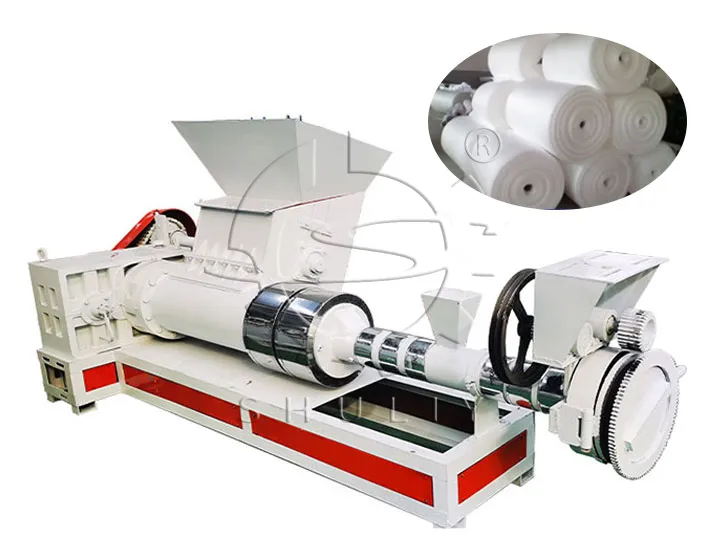

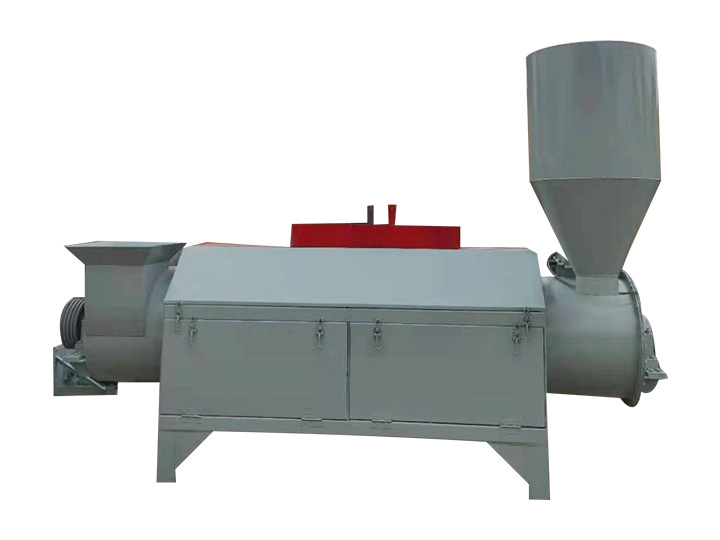

EPS granulator is mainly suitable for foam fast food boxes, foam fresh-keeping boxes, thermal insulation materials, packaging foam of TV sets, air conditioners, refrigerators and other furniture. The waste foam is crushed by the crushing machine, and then the foam scrap will be melted and extruded, and finally formed into plastic pellets.

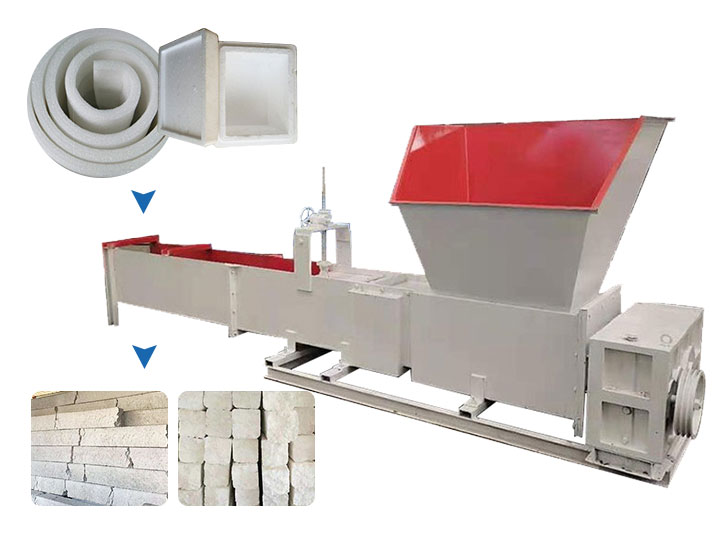

Raw materials of the EPS granulator

As the name suggests, the raw materials of the EPS plastic granulator are waste plastic made from EPS. For example, foam fast food boxes, foam fresh-keeping boxes, thermal insulation materials, packaging foam of TV sets, air conditioners, refrigerators and other furniture. The eps foam blocks for surfboards are also suitable.

Process of the EPS recycling

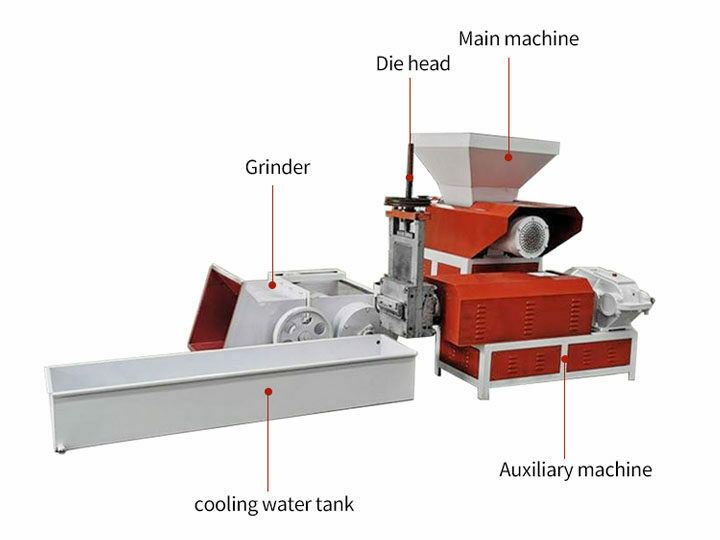

The main process in the EPS foam recycling line is very simple. Firstly, crush the waste plastic foam with a horizontal crusher, secondly, the host machine of the EPS granulator will melt the plastic and extrude it to the auxiliary machine. After a secondary plasticization, the electric screen changing die will filter the impurities, then it enters the cold water pool for cooling, and then enters the pelletizer to cut into uniform granules.

Expanded polystyrene foam recycling machine structure

EPS granulator video

Parameters of the EPS recycling machine

| Type | Capacity (KG/H) | Main motor (KW) |

| SL-220 (double reducer) | 150-175 | 15 |

| SL-270 (double reducer) | 200-225 | 18.5 |

| SL-220 (single reducer) | 150-175 | 15 |

| SL-270 (single reducer) | 200-225 | 18.5 |

| SL-320 (double reducer) | 275-300 | 18.5 |

| SL-350 (double reducer) | 325-375 | 22 |

Is there a market for recycled EPS foam pellets?

EPS foam waste uses a series of recycling processes to turn the waste plastic foam into pellets, which are finally used in the production of new foam products. The prospects and profit margins of waste EPS plastic foam recycling are very large.

With the increasing awareness of environmental protection in various countries around the world, many countries and regions have introduced garbage classification policies to vigorously advocate energy conservation and environmental protection. Therefore, more and more manufacturers have joined the EPS foam recycling industry, from small recycling self-employed to large environmental companies, and even local governments, all participating in the recycling of waste plastic foam.

Many governments and local environmental projects have proactively proposed the application of recycled plastics, so the development prospects of recycled plastics are very impressive. Foam recycling machines such as EPS granulators, foam cold presses and foam hot melt machines have become the market leader.

Applications of recycled EPS pellets

These kinds of particles are called PS regenerated particles, and they have a wide range of uses. The main uses are as follows:

1. Electronic appliances: can be used to manufacture televisions, tape recorders, and various electrical instrument parts.

2. Construction: production of extruded panels (heat preservation Plate), used in the production of transparent parts, optical instruments, and transparent models of public buildings, such as lampshades, instrument covers, packaging containers, etc.

Manufacturers with high demand mainly include exterior wall insulation wall factories, photo frame factories, and billboard factories.

Hot Product

Pioneering waste plastic water ring pelletizer

Due to the advantages of the water ring…

Plastic film cold washing rinsing tank

The rinsing tank is used for rinsing the…

Plastic Bag Shredder Grinder Machine

A plastic bag shredder is a kind of…

PET Bottle Washing Plant Machinery

Our PET bottle washing plant is a suitable…

Plastic Pellet Making machine

A plastic pellet making machine is a recycling…

Cotton Waste Recycling Machine | Garment Rags Tearing Machine

The cotton waste recycling machine is mainly used…

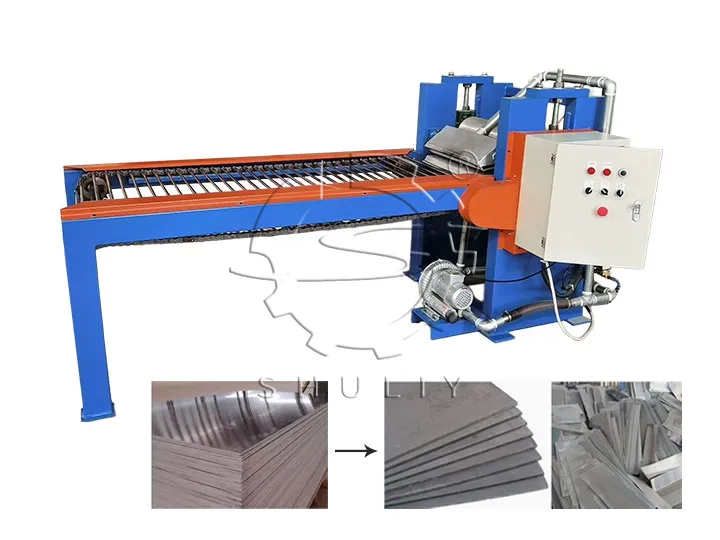

Shuliy SL-Series ACP Recycling Machine

Scrap Aluminum Composite Panels (ACP) from construction and…

Plastic pellet dehydrator

The plastic pellet dehydrator is used to remove…

Vertical & Horizontal Plastic Baler Machine for Bottles Bags Cardboard & More

The commercial plastic baler is mainly used for…