Rubber powder production line | waste tire recycling plant

Rubber powder production line, also known as waste tire recycling plant, is designed to recycle scrap rubber for making crumb rubber or rubber granules. The crumb rubber manufacturing plant is popular in the rubber recycling business.

What steps are involved in the rubber powder production line?

Ring cutter—strip cutter—lump cutter—coarse crusher—magnetic separator—fine milling—second magnetic separator—screening

Introduction to crumb rubber production line

This rubber powder processing line is specialized for recycling waste tires by crushing them into powder. The rubber powder production line mainly includes a tire ring cutter, strip cutter, block cutter, powder mill, and magnetic separator. There are various kinds of tire that can be reused, including car tires, agricultural vehicle tires, bus tires, industrial vehicle tires, etc. The size of reclaimed rubber powder has different mesh to meet different orders.

Related machines of waste tyre recycling line

Tire ring cutter

For cutting the tire side, we can use the ring cutter. This used tire recycling equipment is used for cutting and separating the steel mouth, sidewall, and crown of used tires, and is the first process for recycling used tires.

The basic principle is to select the inner ring of the tire as the support point and the inner ring on the support frame. Move the tool while the tire is running at low speed, cut it into the tire, and cut the tire smoothly.

Strip cutter

This strip cutter can cut the tire when removing wire into strips. This rubber tire cutting tool is simple, reasonable in design. The width of the strap is adjustable, two-disc knives are made of special metal heat treatment, which is hard and durable and can be used repeatedly.

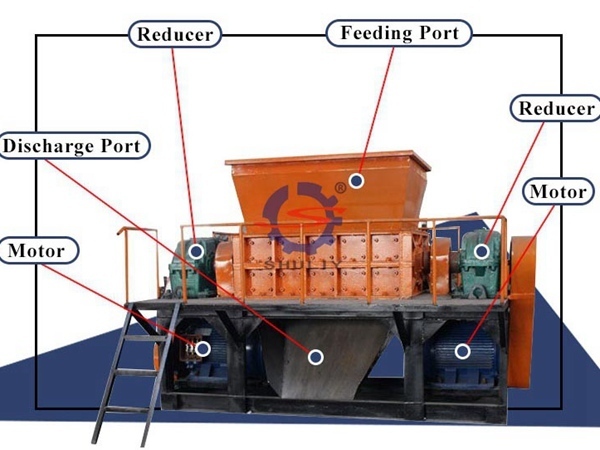

Tire block cutter

The lump cutter is mainly used to cut rubber strips into pieces of a certain size. The blades are made of alloy, when blades are not sharp enough, they can be sharpened repeatedly. This machine is affordable, easy to operate, and environment friendly, it is durable and pollution-free.

Bead wire separator

This machine is mainly used to separate the rubber from the steel ring of the tire from the heel ring to obtain a complete steel cable.

Powder mill and screening unit

The rubber lumps will be crushed by the crusher machine two times. In order to improve the quantity of the rubber granules, we crush the rubber lumps roughly for the first time, then grind them more finely. Rubber particles will be sent to the screening table. This new type of waste rubber granules machine has high output, low energy consumption, high efficiency, and uniform discharge.

Automatic rubber powder production line working video

Waste tyre rim separating and cutting machine

Why is rubber tire recycling so popular?

Waste tire disposal is always an essencial problem for our enviroment.In the past years, waste tires were usually abandoned in landfill. With the development of the industrial vehicle business, the number of used tires has increasingly grown, they occupied a lot of space, what’s more, they became habitats for rats and mosquitoes to breed, which has threatened the environment seriously. Sometimes the waste tires got burnt and released dangerous toxins, which polluted the air a lot. The “black pollution” is threatening our planet. Therefore, recycling tires by rubber powder production line is the best way to solve this problem.

Our services of crumb rubber processing plant

Our delivery time is one month, from the receipt of an order to the goods arrive at the port.

The goods will be dispatched on time, and customers can check the logistics information during the transportation. When customers receive the goods, we will offer instructions and installment videos of rubber powder production line. We can also offer a live stream or organize our engineer to your plant to instruct. Except for wearing parts, quality assurance within one year, lifetime maintenance. Our company keeps integrity management and quality assurance. Welcome to consult or tire recycling plant.

Hot Product

PP PE Plastic Crushing and Washing Machine

The plastic crushing and washing machine is mainly…

Pioneering waste plastic water ring pelletizer

Due to the advantages of the water ring…

Plastic Bag Shredder Grinder Machine

A plastic bag shredder is a kind of…

EPS/Styrofoam Densifier Hot Melting Machine

Descriptions of the styrofoam densifier The styrofoam densifier…

PET bottle flakes hot water washing tank

The hot water washing tank is suitable for…

Plastic pellet bagging machine | Packing machine

Waste plastic needs to be packaged completely after being processed…

Tire Strip Cutting Machine for Efficient Tire Recycling

The processing of scrap tires requires reliable and…

Industrial Rubber Floor Tiles Making Machine for High-Density Production

The SL-120T Pro is a professional-grade rubber floor…

EPE Recycling Machine for Foam Pelletizing

Waste EPE foam pelletizing machine is suitable for…