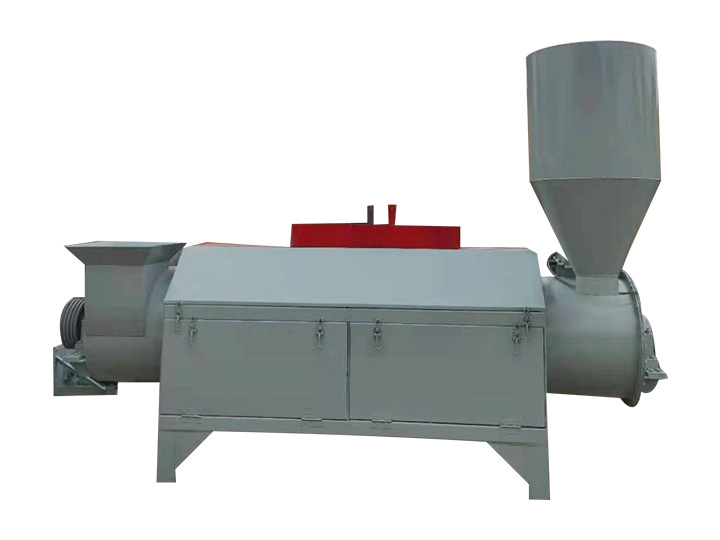

Plastic pellet dehydrator

Plastic dewatering machine | Hydralic plastic centrifugal dewatering Machine

Plastic pellet dehydrator

Plastic dewatering machine | Hydralic plastic centrifugal dewatering Machine

The plastic pellet dehydrator is used to remove water after plastic pieces are washed in the washing machine. The horizontal type is more suitable for the PP PE flake recycling line.

Introduction of plastic dewatering machine

The plastic pellet dewatering machine uses spiral, push-up, separation, and dehydration, and automatically feeds and discharges at one time.We use it to remove water from materials after washing the plastic.

Suitable for plastic films polyester sheets, cable skins, wire tubes, etc.

Horizontal plastic dryer machine working principle

The PP particles after blanching contain a certain amount of water and cannot be used directly. The plastic pellet dehydrator machine is mainly used for the dehydration function of PP pellets so that the finished product can meet the storage requirements. The wet PP particles are gradually raised by the auger of the plastic pellet dehydrator machine, and more water is extracted by the principle of high-speed rotation. The machine can automatically feed and discharge, with no need for manual operation, and greatly improve work efficiency.

The working principle of a horizontal plastic dewatering machine is to remove water or moisture from plastic materials by using centrifugal force. The plastic materials are loaded into a horizontal drum or basket with a perforated surface. The motor rotates the drum or basket at a high speed, generating centrifugal force that pushes the water out of the plastic materials through the perforated surface.

The duration of the drying process depends on the type of plastic material, the amount of moisture present, and the speed of rotation. The dried plastic materials are then discharged through a port located at the bottom of the drum or basket.

Usage of horizontal dryer machine

The plastic drying machine is suitable for PET flakes, polyester sheets, wire tubes, cable skins, etc. We choose this recyclng machine for PP PE flake recycling line and PET bottle recycling line.

Plastic pellet dehydrator parameters

| Model | SL-550 |

| Outer diameter | 550mm |

| Length | 1000mm |

| Filter hole diameter | 4mm |

| Capacity | 1000kg/h |

The model of the plastic dryer machine is named by its outer diameter, the outer diameter is 550mm, therefore, in order to remember it, we call this model SL-550. This model can deal with all kinds of plastic washing or pelletizing lines in a plastic recycling factory.

Function of plastic dryer

The plastic dryer is a simple and effective cleaning and dewatering equipment for recycling waste plastics. It plays an important role in the transportation process. At the same time, the plastic dryer machine completely replaces the feeding link and adds cleaning and high-speed dewatering functions, called advanced automated flow production equipment.

Features of plastic centrifugal dewatering dehydrator

1. Stainless steel structure prevents the material from being polluted.

2. The aluminum crust, effective thermal insulating

3. The hopper can be separated from the stand for easy cleaning.

4. High output and dryness

5. The high-precision temperature controller to control temperature accurately.

Plastic centrifugal drying machine specifications

1.This plastic drying machine is widely applicable to dewatering for crushed material of plastic, just as PET bottles, flakes, sheets, etc.

2. Screen, using high-quality stainless steel material, rotor, and body, equipment is durable;

3. Production of advanced technology, the spindle through dynamic and static balance, rational design, low noise, easy to clean, you can easily open the body, remove dryer internal sieve impurities;

4. Good drying effect, less power consumption, and efficiency, continuous production, a high degree of automation, saving;

5. In addition to dehydration, a plastic drying machine can wash the plastic micro-small debris such as sand.

Hot Product

Vertical foam cutting machine

The Vertical foam cutting machine is dedicated to…

Plastic pellet bagging machine | Packing machine

Waste plastic needs to be packaged completely after being processed…

Strand Pelletizer Machine for Rigid Plastic Recycling

Strand pelletizer machine offer recycled pelletizing technology for…

Tire Strip Cutting Machine for Efficient Tire Recycling

The processing of scrap tires requires reliable and…

Horizontal Styrofoam Shredder

A horizontal styrofoam shredder is mainly used to…

PP PE Plastic Crushing and Washing Machine

The plastic crushing and washing machine is mainly…

Plastic film cold washing rinsing tank

The rinsing tank is used for rinsing the…

PET bottle flakes hot water washing tank

The hot water washing tank is suitable for…

Waste Plastic Crusher for PP LDPE HDPE Recycling

A waste plastic crusher cuts plastic materials into…