Plastic profile extrusion line | PVC ceiling making machine

Plastic profile extrusion line | PVC ceiling making machine

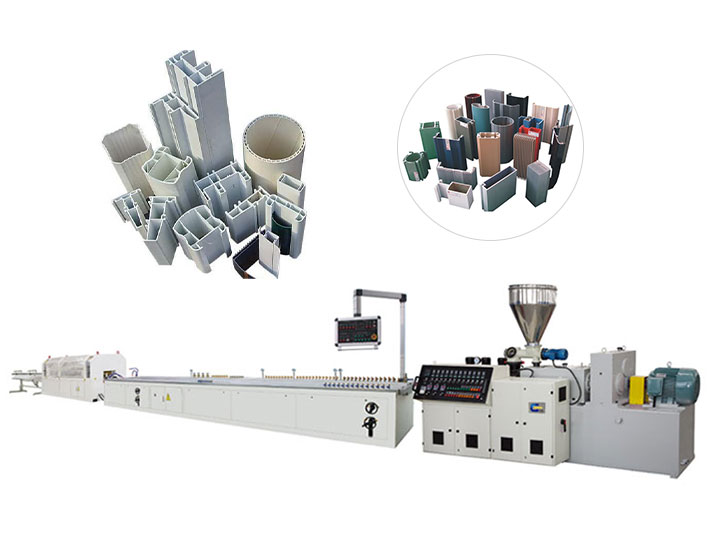

Shuliy plastic profile extrustion line is a professional production line to make PVC panels, plastic boards, porous threading pipes and so on. The complete PVC ceiling making machines include one double screw extruder, one vacuum forming table, one haul-off unit, one cutting unit and one turnover rack.

PVC ceiling making machine introduction

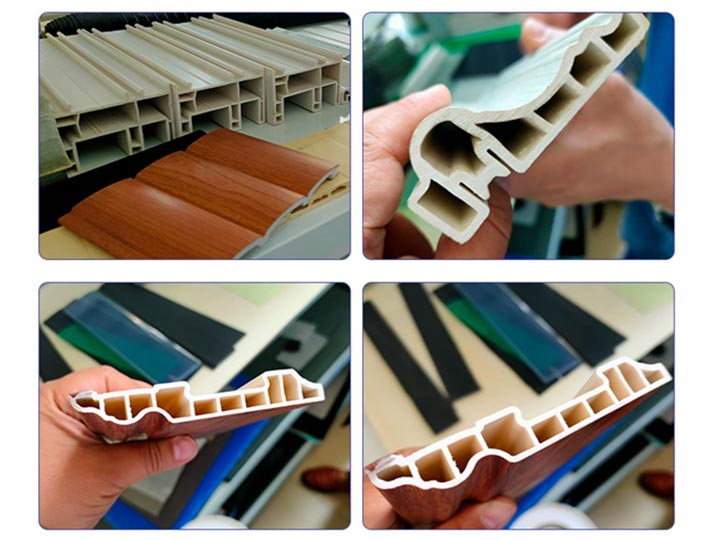

The plastic profile extrustion line is mainly used to produce PVC door panels, window frames, window sills, stair handrails, wiring troughs, skirting boards, special-shaped pipes, etc. The raw materials are mainly rigid PVC, and a few are semi-rigid PVC, soft PVC, low-foaming polyurethane and other materials. This production line can choose different specifications of screw extruders according to the section and mold of different profiles, and is equipped with corresponding auxiliary equipment.

Finnal product of PVC panel making machine

Market expectation of PVC ceiling making machine

Plastic profile products are widely used, the market demand is huge, and the development prospect is very good. In recent years, the production of plastic profile machines has also developed rapidly. The market competition is becoming more and more fierce, and all plastic machinery manufacturers have to consider a problem, how to improve the productivity and qualification rate of plastic profile products under the premise of ensuring product quality, and exerting the maximum capacity of the equipment to reduce the production cost of products.

Shuliy machinery is an excellent manufacturer of plastic profiles. We attach great importance to the research on the industry market, especially the in-depth research on the trend of customer demand.

Main equipment of plastic profile extrusion line

Step 1:Double screw extruder

The extrusion production efficiency of the main machine is between 60 kg and 700 kg per hour, and customers can choose according to their needs.

Step 2: Vacuum forming table

The machine adopts a special enlarged eddy current cooling system for easy cooling and forming, which will meet the requirement of high capacity.

Step 3: Haul-off unit

The haul-off unit adopts our company’s unique lifting technology, which works smoothly and has large traction.

Step 4: Cutting unit

The speed of the cutting unit is the same as the haul-off device. The cutting device adopts PLC computer control, automatically fixed-length cutting, and automatic dust recovery

Turnover rack

Technical data of plastic profile extrusion line

| Items | YF180 | YF240 | YF400 | YF600 | YF800 | YF1000 |

| Max width of board | 180 | 240 | 400 | 600 | 800 | 1000 |

| Drawing height | 140 | 140 | 140 | 140 | 140 | 140 |

| Drawing force | 15 | 30 | 30 | 40 | 50 | 50 |

| Drawing speed | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

| Auxiliary equipment sum power | 18.7 | 31.6 | 31.6 | 31.6 | 31.6 | 37.1 |

| Compression air | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

Features of plastic profile extrusion line

- All electrical components of the PVC profile extrution line are imported brands, these brands include Siemens, Schneider, Omron, ABB, etc. The quality of the big brands is guaranteed and the machine has a long service life.

- All the door panels of all machines are made by spraying and baking paint process, which does not lose paint and can keep the color vivid even for long-term use.

Factory environment

Hot Product

Frictional washing machine for PET bottle recycling

Working process of the frictional washing machine As…

Automatic rubber powder production line

The automatic rubber powder production line is used…

Vertical foam cutting machine

The Vertical foam cutting machine is dedicated to…

Cooling tank | Pellet cooling machine

The plastic cooling tank is a very important…

OTR Tire Steel Debeader for 1800-4000mm Mining Tires

The single greatest hidden cost in OTR tire…

Belt climbing conveyor | Inclined transport machine

A belt climbing conveyor is an essential machine…

Rubber powder production line | waste tire recycling plant

The rubber powder processing line is specialized for…

Pioneering waste plastic water ring pelletizer

Due to the advantages of the water ring…

EPS Granulator | Expanded Polystyrene Foam Recycling Machine

EPS granulator is mainly suitable for foam fast…