Waste Plastic Crusher for PP LDPE HDPE Recycling

PP PE plastic shredding machine | Plastic scrap cutting machine

Waste Plastic Crusher for PP LDPE HDPE Recycling

PP PE plastic shredding machine | Plastic scrap cutting machine

Features at a Glance

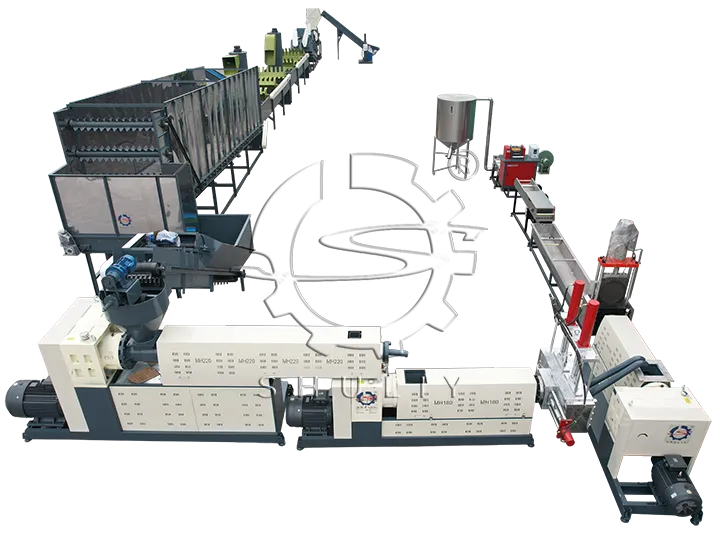

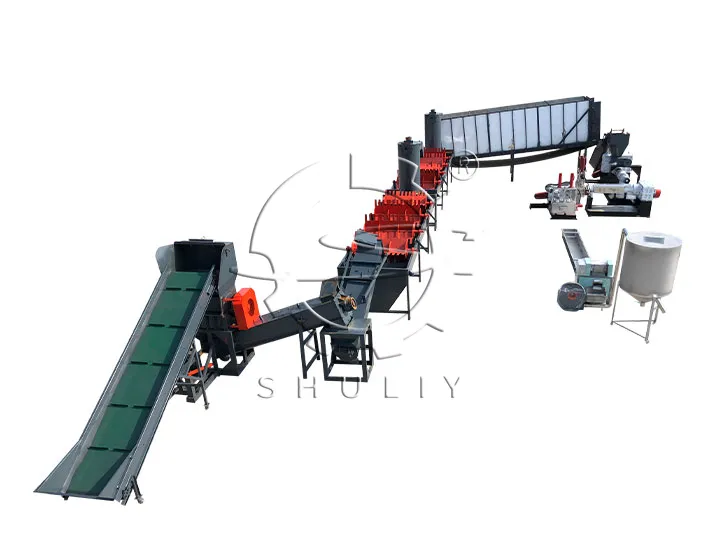

The waste plastic crusher SL-60 and SL-80 are designed for high throughput rates, they are also called waste plastic cutting machines. they can crush almost all types of plastic. Plastic lumps, crates, films, bag scrap, pipes, automotive scrap, and blow-molded materials such as PE/PP bottles, PET bottles, buckets, drums and containers.

The first step of plastic recycling and sustainable processing is shredding with Shuily crushers. Crushing is the basis for all products made from recycled plastics. Both motor and diesel power shredders are available from us.

plastic crusher for waste recycling

plastic crusher for waste recycling diesel engine shredder machine

diesel engine shredder machine diesel plastic shredder

diesel plastic shredder

Introduction of waste plastic crusher

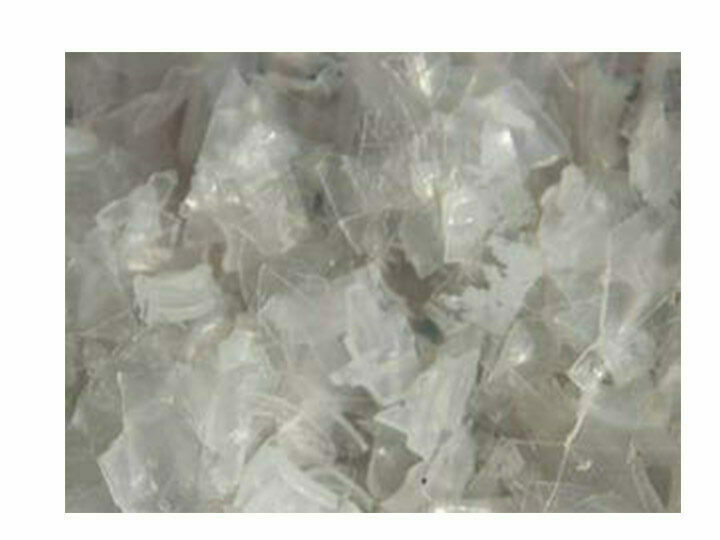

The waste plastic cutting machine is used for crushing the PP PE material to small chips, it has the characteristics of high efficiency, low noise, and no slag material.

Shuliy industrial plastic crushers are extremely flexible and offer different rotor types, blade materials and screen sizes, therefore, they can crush a wide range of waste plastics. For example. thermoplastics such as PE, PP, PVC, PS, PU and PET, as well as injection molded product waste and blown films.

Even large-volume hollow bodies, long pipes and profiles, massive plastic lumps and bulks, as well as PET bottles, textile fibers, foils, insulating materials, crates and containers master industrial Shuliy crushers effortlessly thanks to 20 years of experience in the plastics industry.

Together with Shuliy crushing equipment recycling solutions, we develop single and multi-stage recycling processing, including crushing, pelletizing, and turn to plastic production directly in order to optimize the plastic lifecycle in the long term.

Wet washing for film materials

For the light weight of the plastic film, Shuliy recommends the recyclers use wet crushing method. Adding a water pipe for the plastic cutting machine. Using the impact of water flow, we can reduce the possibility of film stuck in the blades or rotor.

At the same time, the wet crushing process can enhance the water-cleaning effect of plastic scraps and reduce the friction heat due to the cooling effect of water, prolonging the service life of the blade, low maintenance cost, and long service life, therefore, so this kind of waste plastic crusher has received unanimous praise from customers.

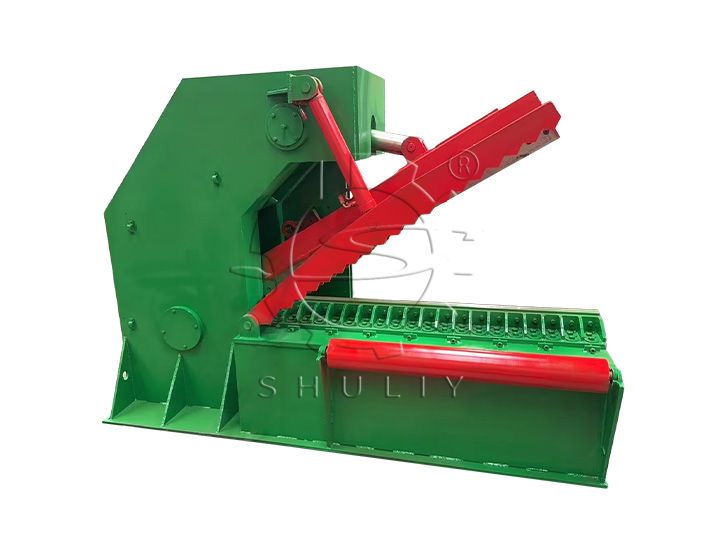

Adjustable knives make perfect cutting gap

The interaction between the crushing blade and the fixed blade has an important impact on material throughput, as well as the crushing results. Typically, due to the different plastic materials, smaller clearances are required for shredding film materials and larger clearances are required for shredding hard materials.

To achieve an accurate cutting gap even when the blades are naturally worn, the Shuliy crusher has an adjustable bottom knife. The optimal cut shape maintains energy efficiency in shredding, minimizes wear costs, and significantly prolongs knife life.

Ready for fast material transport thanks to conveyor technology

Crushers with conveyor belt openings for efficient material transfer are ideal for recycling lines. For example, conveyor belts with a diameter of up to 500 mm are used in film pelletizing lines commonly. Additionally, discharge efficiency can be increased with fans, screw conveyors and U-conveyors.

Crushing rigids or films? You have choices with one crusher

Choosing the right screen is closely related to the shredding effect and output. Therefore, Shuliy Machinery, to give our customers maximum flexibility, i.e., convenience in processing different materials, our machines have individually replaceable screens.

Users can choose screens with different diameters mesh. Typically, a 40-50 mm screen is required to pulverize film materials, while hard materials such as car bumpers, meters, electric waste, crates or pipes need to be replaced with a 20-25 mm screen.

Plastic crusher machine application

The crusher for plastic waste is used to crush various plastics. The PP PE plastic shredding machine can crush a variety of soft and hard plastics, such as plastic tubes, plastic rods, plastic films, plastic toys, waste rubber products, and so on. Our plastic shredder uses alloy steel blades, which have high hardness and a long use time.

The crushed rigids can be called plastic regrinds, they can be reprocessed and pelletized in the next recycling process.

Read more:

Working principle of waste plastic crusher

The waste plastic crusher drives the movable cutter head to rotate at high speed through the motor. In the process of high-speed rotation of the moving knife and the fixed knife, a relative movement trend is formed. The plastic crusher machine uses the gap formed between the movable knife and the fixed knife to create a cut for the plastic crushing and shearing, so as to smash the large pieces of scrap plastic. The crushed plastic is filtered and output by the screen to filter the plastic particle size. In addition, if your raw materials are soft plastics like plastic films and bags, it’s better to add a fan on the plastic crusher to avoid clogging.

Plastic scrap cutting machine for PP film video

The video shows a complete PP PE plastic washing recycling plant, the crusher is the essential step of it.

Crusher working process for rigid plastics

Parameters of PP PE flakes shredding equipment

The following parameters are the basic data of the Shuliy plastic crusher machine, if interested, consult us or leave your requirement on our website, and we will explain them to you one by one.

| Model | SL-60 | SL-80 |

| Capacity | 500kg/h | 1t/h |

| Blade material | 60Si2Mn | fan for soft material, belt conveyor, screw conveyor, blade sharpener |

| Blade width | 60cm+30cm | 80cm+40cm |

| Power | 15+7.5kw | 30+11kw |

| Screen mesh diameter | 20-50mm | 20-50mm |

| Optional auxiliary device | fan, conveyor, blade sharpener | same as SL-60 |

The waste plastic crusher model is different from the blade width. The machine power and capacity are also different. Apart from SL-60 and SL-80, we also offer many other models of machines. For other needs, welcome to send us your requirements.

Precautions for the operation of crusher for plastic waste

1. The plastic crusher machine and power unit should be installed firmly.

2. After the waste plastic crusher is installed, check the fastening of each fastener.

3. Before starting the PP PE flakes shredding equipment, turn the rotor by hand to check whether the claws, hammers, and rotors are running normally and whether the power machine and the plastic crusher are well-lubricated.

4. After the plastic crushing machine is started, it should be kept idling for 2-3 minutes first, and make sure that there is no abnormal phenomenon before feeding work.

5. Pay attention to the operation of the plastic crusher machine at any time during the work. First, the feeding should be uniform to prevent from being blocked; secondly, do not overload the work for a long time. If any abnormal phenomenon is found, it should be stopped immediately for an inspection.

Global cases of waste plastic crusher

Post-industrial film shredding with a Shuliy SL-60, Kenya

- Learn more about the shredding story: Ethiopia recycling & crushing

Shredding of post-consumer rigid plastics with a Shuliy SL-80 crusher, Tanzania

- Learn more videos and crushing story: Crushing machine installation in Tanzania

Over 40 countries’ clients chose Shuliy crusher

Shuliy PP PE flakes shredding equipment is installed and in operation in over 40 countries worldwide. Some foreign customers visit Shuliyd’s factory. Some customers communicate with our sales manager on Whatsapp or face to face video for detailed discussion. shuliy has some customers referred by regular customers because of the company’s reputation and the quality of the machines.

The following pictures show the projects of our customers.

A field trip for plastic crusher machine

You have the possibility to send us your recycle material, you can also visit us directly in China to observe the shredding process live.

For manufacturers who want to invest in plastic scrap cutting machine, we suggest coming to our company and plant. In order to learn about the equipment and plastic scrap cutting machine price better, a field trip is important.

Customers can see the equipment just beside it, touch the material of the machine, try to operate the plastic recycling machines in person. The plastic recycling machines produced by our company has been purchased by several foreign customers, we can arrange for customers to visit our plant and know the machines better.

Except for plastic crusher machine for PP PE materials, we also provide PET crusher machines, which is a little different from the former. If interested, welcome to contact us by the website form.

Waste plastic crusher FAQs

What is the purpose of “wet crushing” and when should I use it?

Wet crushing, which involves adding water into the crushing chamber, is highly recommended when processing light materials like plastic film. It offers three main benefits:

Improved Feeding: Water makes the film heavier, preventing it from floating and ensuring it’s caught efficiently by the blades.

Longer Blade Life: The water acts as a coolant, reducing friction heat and significantly extending the service life of your blades.

Pre-Washing: It provides an initial clean, washing away sand, dirt, and other contaminants from the material.

How do I choose the right screen size for my material?

We design our machines as part of a complete system. For instance, the friction washer placed after the crusher uses a special U-shaped screw conveyor for film materials. This design is crucial for preventing blockages and allows for quick and easy maintenance, ensuring your entire line runs smoothly with minimal downtime.

How do you ensure the plastic crusher integrates well with the rest of the washing line?

We design our machines as part of a complete system. For instance, the friction washer placed after the crusher uses a special U-shaped screw conveyor for film materials. This design is crucial for preventing blockages and allows for quick and easy maintenance, ensuring your entire line runs smoothly with minimal downtime.

Are the bearings protected from water and dust?

Yes. Our waste plastic crushers feature outboard bearing seats. This important design feature places the bearings outside the crushing chamber, effectively preventing water and plastic dust from causing damage. This significantly extends the life of the bearings and reduces your maintenance costs.

Are you a plastic crusher manufacturer that ships to Africa? For example, Nigeria or Kenya?

Yes, we are a direct manufacturer of industrial recycling machinery with extensive experience shipping globally. We regularly deliver equipment, including our heavy-duty plastic crushers, to clients across Africa. We can arrange shipment to major ports like Apapa in Lagos, Nigeria, and Mombasa, Kenya, and will handle all necessary export documentation for a smooth process.

What is the delivery time and shipping cost for a plastic grinder to the Middle East, like Saudi Arabia?

The standard production time for our machines is 15-20 working days. Sea freight to a port like Jeddah, Saudi Arabia, typically takes an additional 20-25 days. The final shipping cost depends on the crushing machine’s size and weight. We will provide you with a detailed and competitive CIF (Cost, Insurance, and Freight) quotation when you inquire.

I’m looking for a plastic shredder for sale with a good warranty. What does your policy cover?

Every plastic shredder for sale from Shuliy comes with a comprehensive 12-month warranty. This covers any defects in material and workmanship for all major components, such as the main motor and machine body. While consumable parts like blades are not covered, we guarantee they are made from high-quality, wear-resistant alloy steel for long life.

As a plastic crusher supplier to South Africa, how do you provide after-sales support and spare parts?

We pride ourselves on being a reliable supplier with life-long technical support for all our clients. If you are in Johannesburg, South Africa, or anywhere else, you can reach our engineers 24/7.via WhatsApp or email. We stock a full range of spare parts (blades, screens, etc.) for every plastic grinder model we sell and can ship them to you quickly via international courier.

I need a complete wet crusher for plastic film in East Africa. Do you offer on-site installation?

Yes. For clients who purchase a complete system, such as a washing line featuring our wet crusher for plastic film, we can offer on-site installation and training services. Our experienced engineers can travel to your facility in countries like Kenya or Tanzania to ensure your equipment is set up correctly and your team is fully trained on operation and blade maintenance. This service is subject to additional cost and travel arrangements.

Hot Product

Tire Strip Cutting Machine for Efficient Tire Recycling

The processing of scrap tires requires reliable and…

Plastic pellet bagging machine | Packing machine

Waste plastic needs to be packaged completely after being processed…

PET Bottle Crushing Machine

PET bottle crushing machine plays a very important…

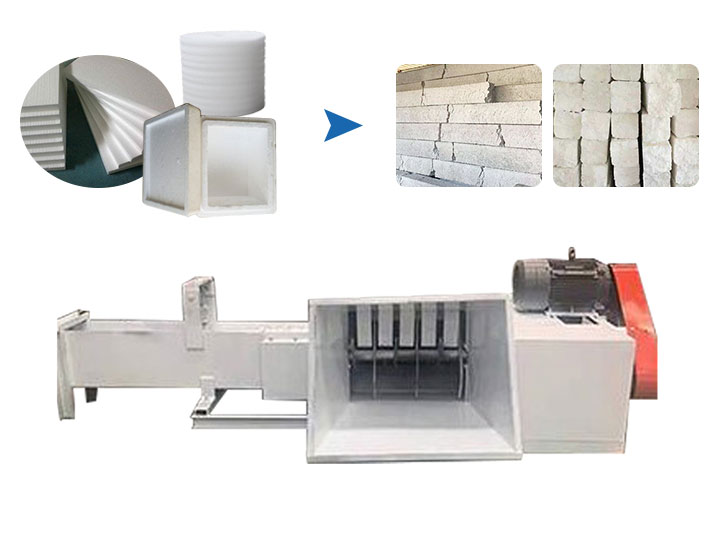

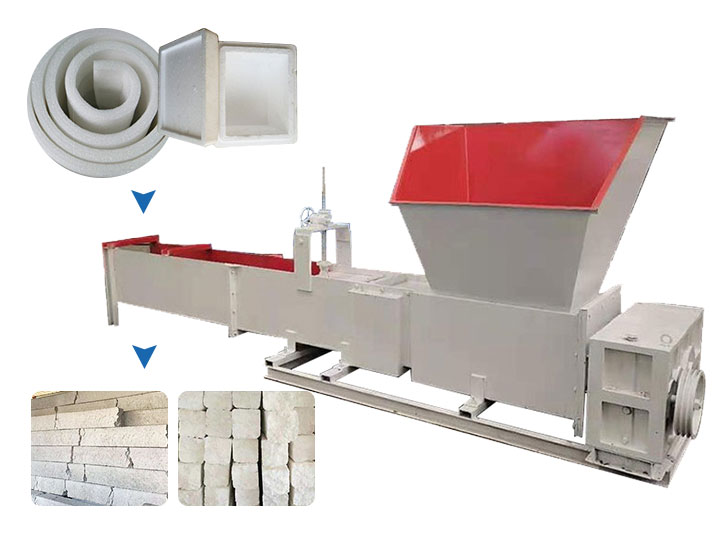

Horizontal EPS Foam Compactor

The function of the horizontal EPS foam compactor…

OTR Tire Cutting Machine for 1400-4000mm Tires

The OTC-4000 is a specialized OTR tire cutting…

Vertical EPS foam compactor | Styrofoam recycling densifier

Vertical EPS foam compactor is one of the…

Plastic film cold washing rinsing tank

The rinsing tank is used for rinsing the…

Plastic Sink Float Separation Washing Tank

Our plastic sink float separation washing tank uses…

EPS Granulator | Expanded Polystyrene Foam Recycling Machine

EPS granulator is mainly suitable for foam fast…