EPE Recycling Machine for Foam Pelletizing

Expanded Polyethylene Recycling Machine

EPE Recycling Machine for Foam Pelletizing

Expanded Polyethylene Recycling Machine

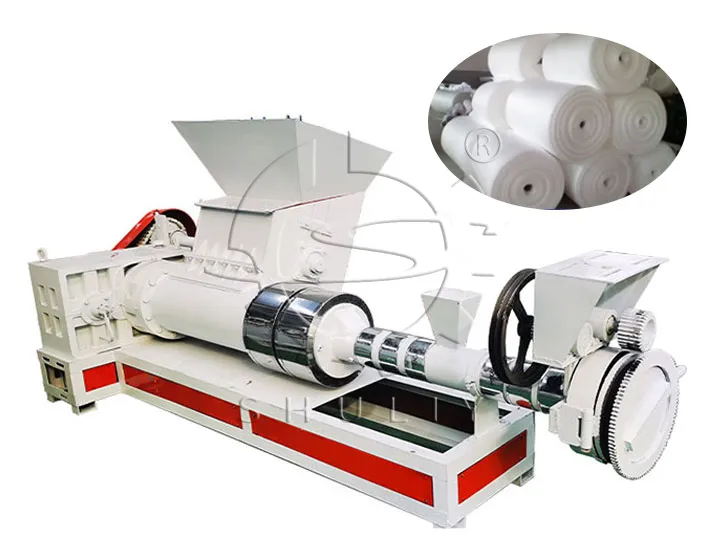

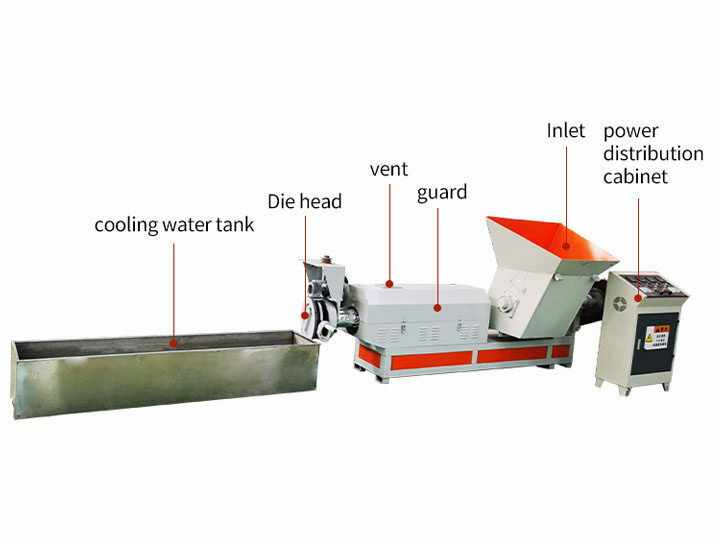

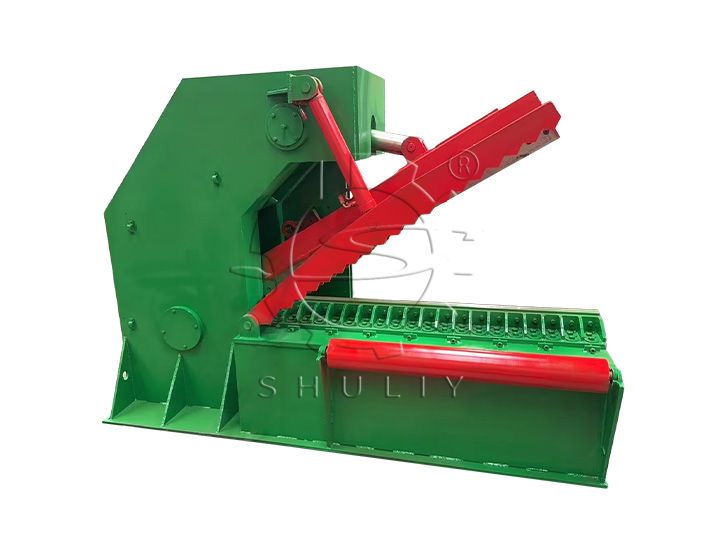

Waste EPE recycling machine is suitable for extruding and pelletizing EPE foamed waste plastics as raw materials, and processed into EPE plastic particles that are in short supply in the current plastics industry, which can be used to regenerate EPE. The EPE recycling machine adopts an exhaust structure to remove the gas generated during the plasticization process of the material so that the granules are dense and the surface is smooth. The production operation process is very simple, the investment cost is low, and it has high economic benefits.

Waste EPE recycling machine overview

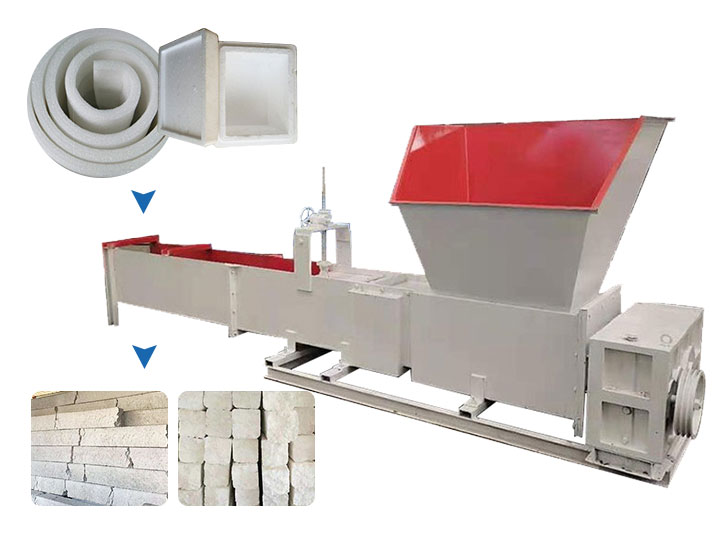

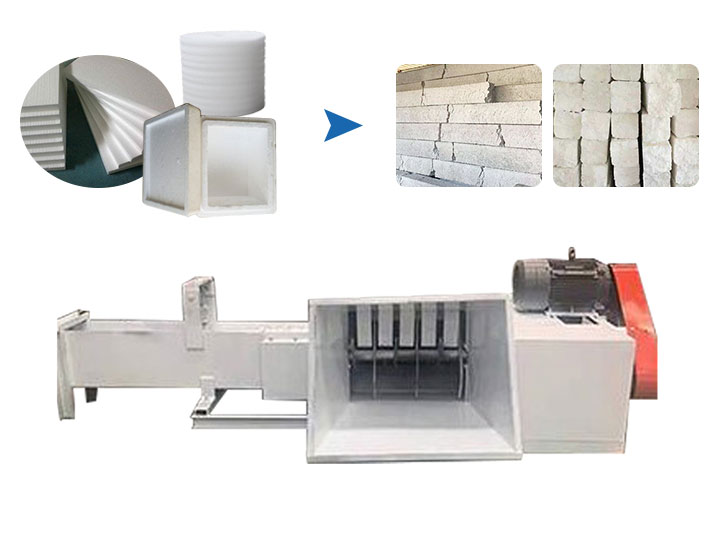

The styrofoam sheet recycling machine structure is mainly used for the recycling, processing, and reuse of various waste foams and pearl cottons, such as various electrical packaging foams, waste lunch boxes, and foam corner waste. After simple processing by the waste expanded polyethylene recycling machine, it can be reused PS recycled particles, this kind of recycled particles is used. This machine is also the main part of the EPE Styrofoam Pelletizing Machine.

Expanded polyethylene recycling machine structure

EPE foam plastic granulating machine can achieve an output of 500kg per hour. The equipment includes a feeding system, a compaction and extrusion system, a vacuum exhaust system, a filtration system, a cutting system, and a dry packaging system. The equipment has the advantages of high output, low energy consumption, and good performance after waste recycling. All electrical standards meet European standards, and the recycling process adopts European recycling technology.

Application materials of EPE foam recycling machine

Plastic films, woven bags, non-woven fabrics, plastic ropes, fishing nets, nylon chemical filaments, EPE foam products, plastic home appliances.

Technical parameter of expanded polyethylene recycling machine

- Model SL-160

- Machine size: 3400*2100*1600mm

- Inlet size: 780*780mm

- Power: 30kw

- Capacity: 150-200kg/hour

- Heating method: heating ring

Advantages of EPE recycling machine

- The new generation of waste EPE foam pelletizing machine adopts new technology, new design, beautiful appearance, and easy to use.

- This set of expanded polyethylene recycling machine has complete supporting facilities and can be automatically and continuously produced. From raw material crushing, drawing to cutting into pellets, all are automated production.

- The full set of waste EPE recycling machine has a small footprint, low power consumption, high quality of finished products, and a wide range of applications.

- It makes full use of the high-pressure friction continuous heating system to automatically heat production, avoiding continuous heating by the heating system and saving energy and electricity.

- The screw and the discharge port are made of imported high-strength superior carbon structure lead steel, which is durable and not easy to deform.

Hot Product

Waste tire recycling line | rubber granules making machine

The waste tire recycling line uses advanced tire…

OTR Tire Cutting Machine for 1400-4000mm Tires

The OTC-4000 is a specialized OTR tire cutting…

EPS Granulator | Expanded Polystyrene Foam Recycling Machine

EPS granulator is mainly suitable for foam fast…

Vertical type dewatering machine for waste plastic films

A vertical type dewatering machine is used for…

Pioneering waste plastic water ring pelletizer

Due to the advantages of the water ring…

Rubber powder production line | waste tire recycling plant

The rubber powder processing line is specialized for…

Industrial Rubber Floor Tiles Making Machine for High-Density Production

The SL-120T Pro is a professional-grade rubber floor…

Rigid Plastic Shredder Machine

Shuliy rigid plastic shredder machine is also called…

Horizontal Styrofoam Shredder

A horizontal styrofoam shredder is mainly used to…