How to maintain an EPS foam granulator machine?

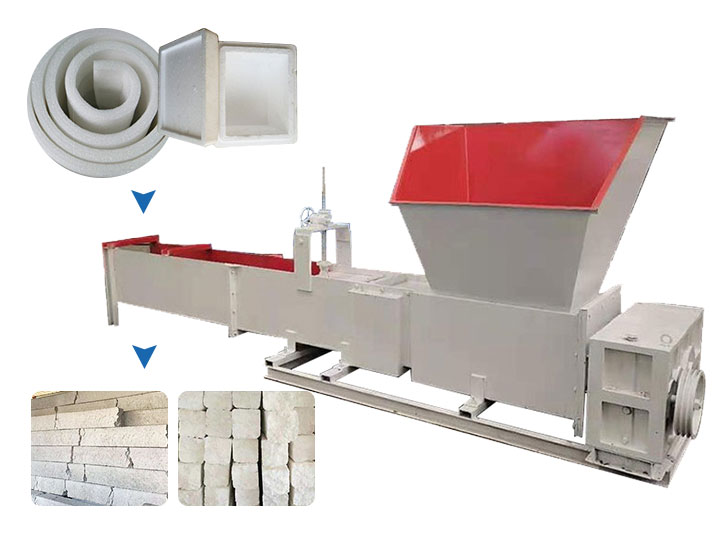

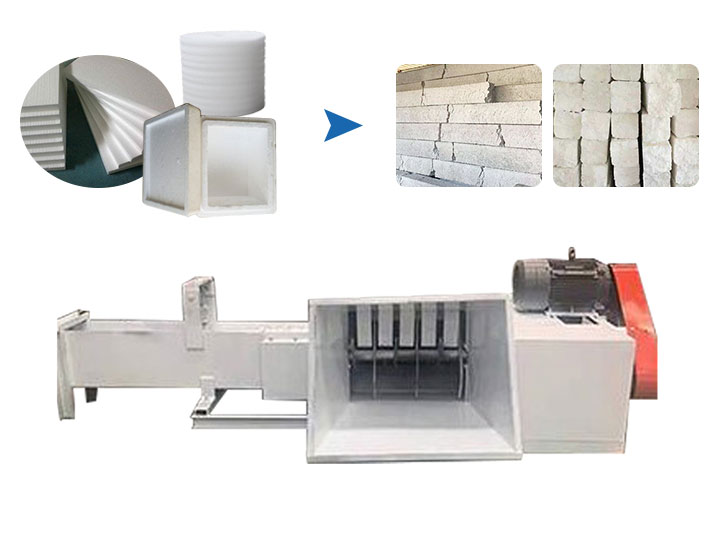

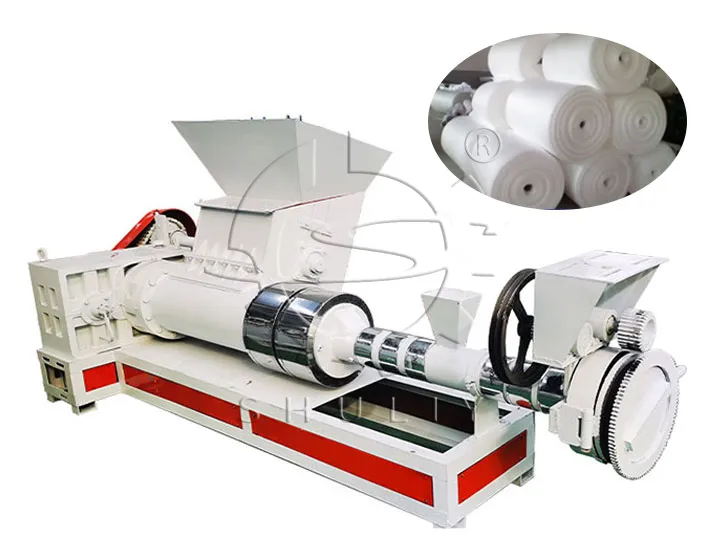

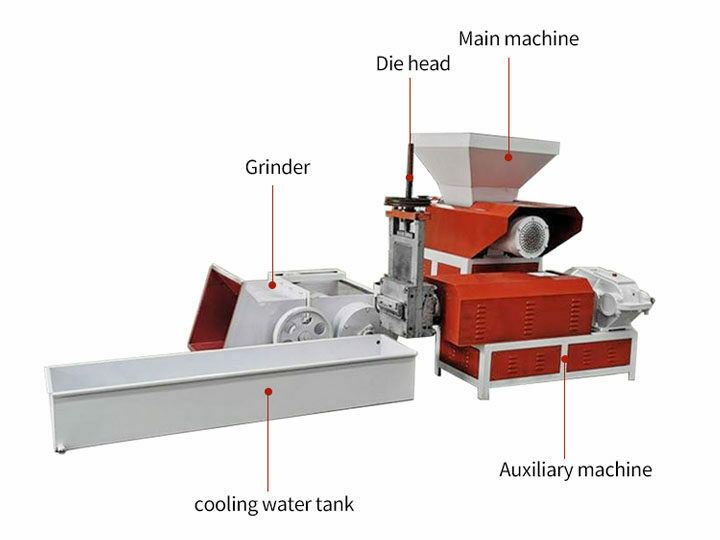

The waste EPS foam granulator is the main machine in the EPS foam granulating line. The foam granulator adopts high-temperature melting and foaming and is made into granules after a series of drawing, cooling, and cutting. In this process, the most important thing to pay attention to is the heating of the host.

The question that many customers often ask is: the first time you use it, you only need to heat it for half an hour; why the second time you need to heat it for an hour? What is the reason?

This is because the remaining material on the screw did not flow out after the first day of production, causing the inside to cool and solidify overnight, so it took a long heating time to melt. In this case, the blowtorch can be used to accelerate the temperature rise and make it melt quickly.

So the most important thing is to keep the material flowing clean before shutting down. One is to save time, and the other is to save energy.

In addition, if the machine is not completely melted when the machine is started, it will increase the wear of the screw. In severe cases, it may cause damage to equipment components, with disastrous consequences. This is the most important part of our maintenance work.

In addition, we need to add oil in time and clean the parts regularly to keep the equipment in good condition at all times to get the best-finished product.

Long-term maintenance of EPS granulator

During November, several customers called us to consult us: The foam recycling granulator equipment purchased from you in the past is not very easy to use at work, and the rotation is not as flexible as before. What should I do?

The reason for this problem is actually relatively simple. The machine lacks oil or is caused by a lot of dust in the chassis. Below, we will introduce some maintenance knowledge about the foam granulator:

- Check the working conditions of the rollers once every six months, clean the bearings on the rollers with inflexible rotation, add grease, and replace the worn or damaged bearings in time.

- For the newly put into the production of the foam recycling granulator, after the production test run time reaches 500 hours, all lubricating parts should be drained; the oil cup, fuel tank, pipeline, and filter should be cleaned, and then new filtered oil should be added.

- Check the wear of the brushes of the DC motor once a month, adjust the contact position of the brush and the shaft, replace the brush with a new one if necessary, and clean the fan on the motor at the same time.

- The air source dual lubricator should be filled with turbine oil once a month, and the moisture in the air filter should be removed at the same time.

- Sweep away the dust and dirt in the electric control box quarterly or half a year, check the amount of lubricating oil in the oil tank and replenish the amount of lubricating oil in time.

- Clean the air filter on the gearbox every quarter or half a year, adjust the tension of the V-belt or chain, check the sealing ring (pad) in the pneumatic system, and replace the worn parts when necessary.