在废塑料造粒过程中,有两种最常用的造粒方法。一种是将挤出的塑料条在水箱中冷却,然后用塑料造粒切粒机的滚刀将其切成颗粒;另一种是使用水环模面切粒机。由于水环造粒机的优点,水环造粒机越来越受到塑料回收加工行业从业者的青睐。模面切粒机切出的塑料颗粒圆润、均匀、外观美观。此外,与传统的切粒机相比,水环造粒系统节省了场地和人工成本,产生的废料也更少。

什么是PP PE塑料水环造粒机?

塑料水环造粒机是一种用于塑料造粒生产线的设备,适用于大多数热塑性塑料的造粒。模具面造粒系统是指废弃的PP塑料或PE塑料在从模具表面出来时立即被切割成颗粒。由于塑料材料在高温下被切割成颗粒,模具面切割机也是一种急切切割的形式。生产的塑料颗粒被抛入高速旋转的水流中,然后送入脱水设备。

阅读更多:

适用材料

模具面塑料切割机适用于PP薄膜、PP编织袋、PP吨袋材料、PE薄膜、PP/PE破碎材料。

为什么在塑料回收生产线中需要水环造粒机系统?

- 光滑均匀的塑料颗粒。 模具切割回收机采用热切水冷法,塑料颗粒光滑圆润,形状均匀且无孔。均匀的颗粒为后续产品的生产和加工质量以及成本和费用的控制带来了极大的便利;

- 可调颗粒大小。 由于模具面切割机挤出机的电机采用变频调速,因此颗粒化速度可以调节,因此可以通过调整切割机的速度来调整颗粒大小,以满足客户的要求。

- 节省空间。 在水环造粒机的使用中,不需要像传统切割工艺那样使用冷却水箱,因此占地面积小,节省了空间。

- 连续操作和节省人力。 水环造粒系统通常与快速换网器一起使用。更换筛网时不会出现断条的问题,也不会影响后续的造粒,因此减少了废料的产生和工人的劳动成本。

- 操作简单,运行成本低。 水环模具面切割机设计紧凑,运行成本低,启动程序简单。

- 高生产效率。 水环模具面切割机有多种输出选项,100-1000kg/h。

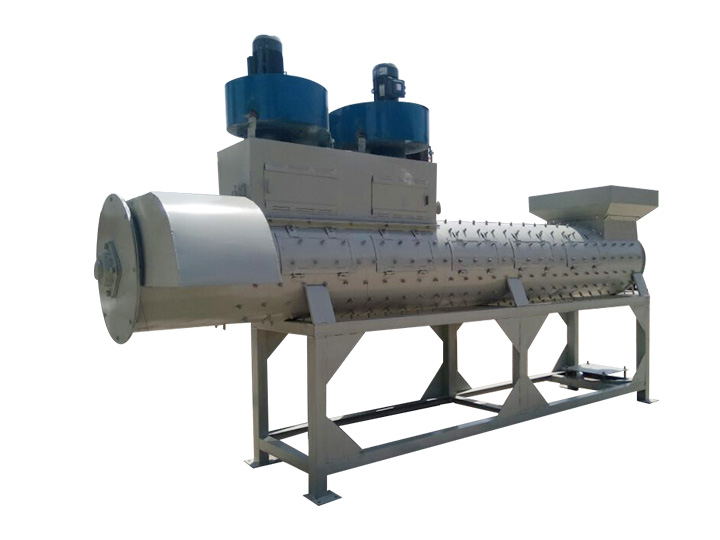

水环造粒机的组成。

水环造粒机主要包括水环造粒模具、造粒系统、水环造粒罩、加热器、水泵、变频器、循环冷却池。该机器可以与脱水机配合使用。模头由模具钢制成,其他部件则由不锈钢制成。可以根据客户要求定制各种水环造粒系统。

模具面切割回收机视频

水环造粒机操作过程

从塑料挤出机的排出模头挤出的长条在离开模具后立即被旋转切割头切割。塑料颗粒被抛入附着在造粒盖上的内腔进行高速操作,并通过水初步冷却。然后,水流将塑料颗粒送入干燥机,随后送入材料冷却设备。这样,塑料颗粒就完成了。

在水环造粒系统中用于冷却和运输的水不与模头接触。由于在模具周围形成了水环,模具与冷却水不接触。这个特性确保了模具温度的均匀性,因此即使产量较低,模头的排出仍然正常。旋转刀具切割熔融丝,并在离心力的作用下将热熔融颗粒抛入循环水中。水流将颗粒带出造粒罩。

热销产品

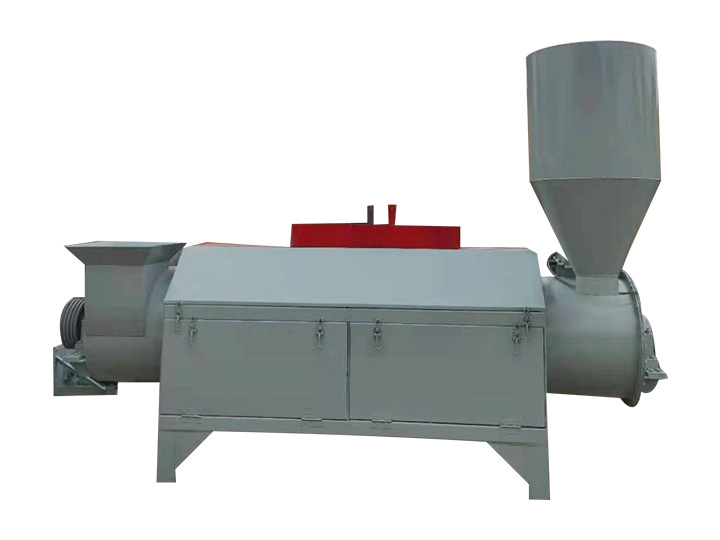

刚性塑料回收绳粒机

条状造粒机提供回收造粒技术用于…

1800-4000mm矿用轮胎的OTR轮胎钢扣去除机

轮胎隐性成本中最严重的一项在于 OTR 轮胎……

静电喷涂机 | 手动粉末喷涂枪

静电喷涂机是用于…的工业设备

带式爬升输送机 | 倾斜运输机

带式爬升输送机是一种必不可少的机器…

PET瓶清洗厂机械

我们的PET瓶清洗厂是一个合适的…

PET瓶标签去除回收机

PET瓶标签去除器是塑料…不可或缺的工具

石蜡蜡粒机|工业石蜡颗粒机

石蜡颗粒机利用低...

塑料颗粒脱水机

塑料颗粒脱水机用于去除…

高效轮胎回收的轮胎条切割机

废旧轮胎的处理需要可靠的和…