Plastic Film Recycling Machine

Polypropylene (PP) & Polyethylene (LDPE LLPE HDPE) pelletizing washing machine | PE PP film reycling line

Plastic Film Recycling Machine

Polypropylene (PP) & Polyethylene (LDPE LLPE HDPE) pelletizing washing machine | PE PP film reycling line

The plastic film recycling machine is highly efficient and can recycle plastic waste into plastic pellets. The plastic pelletizing process does not emit emissions, and the whole project is very environmentally friendly.

Shuliy Group has manufactured plastic pelleting recycling machine for over ten years and exported them to German, Ethiopia, Saudi Arabia, Kenya, and many countries around the world. Now the plastic recycling business can make a high profit for recyclers.

Introduction of PE PP film recycling line

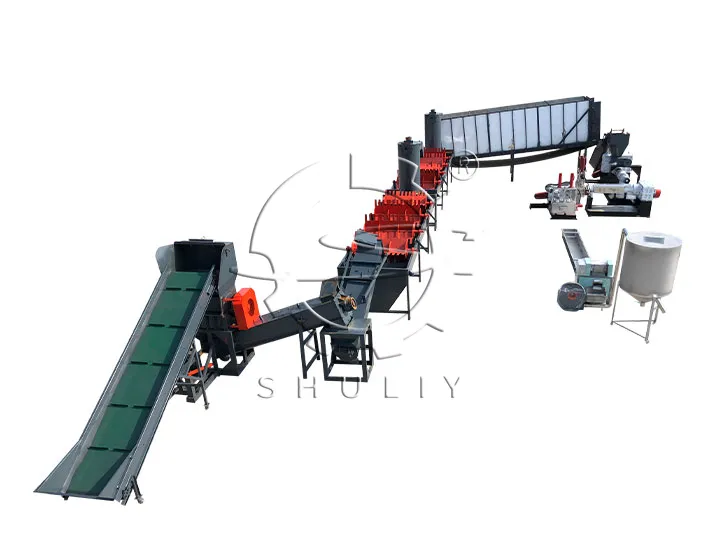

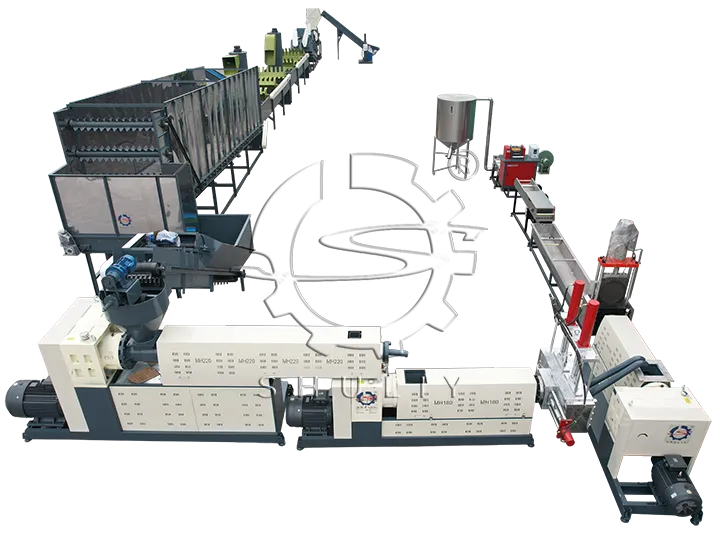

The plastic film recycling machine is specially prepared for various kinds of common plastic film in daily life. The entire plastic film pelletizing line mainly includes a plastic crushing and cleaning machine, rinsing tank, automatic feeding machine, dewatering machine, plastic pelletizer machine, cooling tank, and pellet cutting machine. Our plastic film washing line is available with the output 100-500kg/h.

The capacity of our standard PE PP film recycling line is sufficient for most plastic recycling factories. We also supply additional machines and larger capacity according to your demands.

3D video of the waste plastic film recycling line

Recycle materials of plastic film recycling machine

In daily life, we can see plastic films of various materials, such as beverage packaging films, frozen food packaging films, medical plastic films, and fresh-keeping films,PP raffia bags, cement bags. They are made of PP, PE, etc.

The film washing system can process post-industrial film waste, it is a perfect line for in-house recycling. The washing line is highly recommended for film producers of garbage bags, agricultural films, T-shirt bags, food packaging, laminated films, shrink films and stretch films. Moreover, producers in the woven industry of PP woven bags, tapes, and yarns can also use the line.

IN addition to post-industrial plastic, the plastic film processing plant also can recycle post-consumer waste. LLDPE wrapping film, HDPE LDPE LLDPE film bags for packaging, used agriculture films, waste PP PE woven bags, etc.

Plastic film pelletizing process and workflow

Shuliy provides different pelletizing solutions for different recycle material. The processing methods of plastic films of different materials are slightly different, but most of them need the following steps.

First of all, the collected plastic films need to be crushed into small pieces by a plastic crusher machine, and then they will be washed thoroughly in a washing tank. After that, the wet plastic films will be lifted to a plastic granulator machine, they will be melted as a mushy shape, hot long strips will be extruded from the die head of the plastic granulator machine. Next, those long strips will be cooled in a cold water sink, the cold water can decrease the temperature and make the plastic hard. The last step is cutting plastic strands into small pellets evenly with a plastic granule cutter. Finally, these recycled pellets will be stored in a storage bin.

PP plastic film recycling machine

Woven bag is a very common kind of PP soft material. Some woven bags are dirty and need to be washed twice before entering the next processing step.

Relevant equipment for PP film recycling line

PP film crusher — PP film washing tank — drying machine — PP pelletizing machine — cooling tank — pellet cutter — storage bin for PP pellets

PE plastic pelletizing machine

There is a special type of PE plastic film, namely cling film. In supermarkets, frozen food or fresh vegetable packaging is usually covered with plastic wrap.

Recycling equipment for PE waste film

PE film crushing machine– PE film washing machine — film dryer –PE film granulating machine — cooling tank — pellet cutter– storage device

Plastic film pelletizing machine working video

The specific process of plastic granulation line

Step one: Plastic film crushing

The Plastic crushing machine is mainly suitable for crushing waste agricultural film, PP woven bags, etc. in the plastic film recycling line. It is characterized by water brokenness, water washing, and high efficiency. There is a rotating cutter inside the crusher. The cutter is specially treated to crush the material into small pieces in a short time. The blade can be re-sharpened for durability. The machine is a closed and sealed design for crushing and cleaning.

After the raw materials are put into it, the crushing and cleaning are carried out simultaneously, and the washing cylinder is used for secondary cleaning, which is the highest cleanliness of the plastic.

The casing body is all welded by a thick steel plate, the transmission parts are finely processed, the blades used are made of high-quality steel, and heat-treated, high-quality mechanical quality makes it have high crushing efficiency, low energy consumption, and long service life.

Step two: Washing and remove contamination

The rinsing tank is mainly used to remove dirt from plastic materials. rinsing the broken material to precipitate impurities. There are several models to choose from. It is made of stainless steel or an iron plate. There are multiple toothed agitators installed on the upper part of the PP PE film washing machine, they can force plastic chips to move forward. which can make plastic materials cleaner. The bottom of the conical machine is equipped with a screw pushing device, which can automatically discharge sewage, save labor and save water resources.

Step Three: Lifting and dewatering plastic materials

The dehydrator is divided into a vertical dehydrator.

The structural principle of our vertical-type dewatering machine includes strong swirling cleaning, automatic conveying, self-priming function, high-speed extraction centrifugal dehydration, and flow guiding device. The inside of the vertical dewatering machine is a screw-feeding device, which uses a strong centrifugal force to throw out the water in the material during the screw conveying.

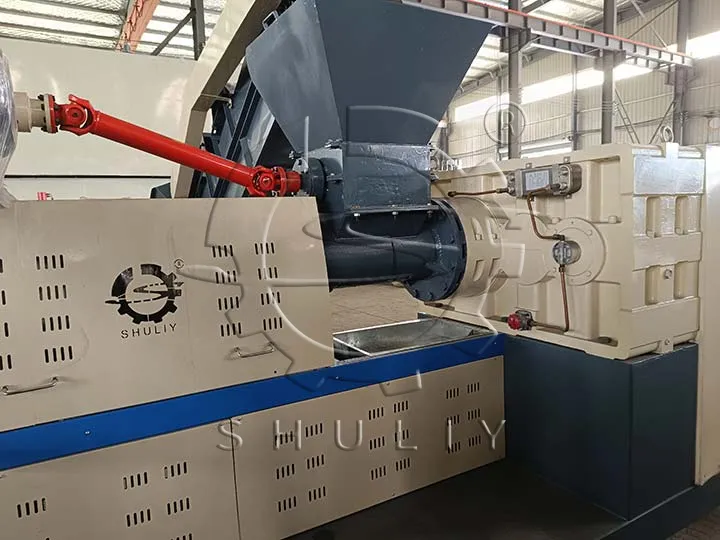

Step four: Plastic extruding and pelletizing

The Plastic pelletizer machine is a device for extruding, cooling, and dicing polyethylene (green film, lining bag, etc.) or polypropylene (old woven bag, packing bag, tying rope, etc.) to produce plastic granules. It is also called a plastic granulator,which is the most important equipment of the plastic film recycling line. The granules produced are widely used and are ideal for investment projects. This equipment is matched with the crushing and cleaning machine and the pellet cutter. Broken and cleaned plastic can be directly put into extrusion granulation. Simple process, advanced technology, and is suitable for different waste plastics.

The plastic granulator adopts automatic temperature control and electromagnetic heating, with less electricity, no pollution, and high automation. The dried material enters the plastic granulator from the feeding port. The material is melted under the heating of the heating ring. The melt plastic flows out from the outlet of the main machine and then enters the auxiliary machine. Under the extrusion of the auxiliary machine, the plastic will be cut by a granules cutter or a water ring cutting device.

Step 5: Cooling the plastic strands

The cooling tank is mainly used for cooling the soft strip plastic material extruded from the plastic granulator, making them hard. It is made of stainless steel, which can ensure no rust and corrosion during long-term contact with water. Also, you can choose an iron type, just choose it according to your demands.

Step six: Cutting plastic stands into small pellets

The plastic pellets that are melted and extruded by the plastic pelletizing recycling machine are in the shape of long strips. In order to facilitate storage and secondary use, plastic pellet cutters are also required to cut the plastic strips into plastic pellets.

This plastic pellet cutting machine has superior performance and reasonable structure. The sealing performance of the whole machine is better, e less leakage, and It is convenient to adjust the cutting distance. the rotary cutter is made by hard alloy hob, its wear resistance is extremely high, and the whole machine without gear design effectively reduces the machine noise with the belt rotation. and the independent electrical box is convenient and safe. Cold-drawn pelletizing for various high-yield, high-strength engineering plastics.

Step seven: Stock plastic pellets

The prepared plastic granules can be directly packed in woven bags or put in storage bins made of stainless steel. There is a pump in the lower part of the storage bin, which can continuously suck plastic particles into the inside of the machine.

The storage bin has many features. Firstly, the storage bucket and the wind-feeding material are combined into one, occupying less land and saving labor. Secondly, it can be docked with various granulators for easy movement. Thirdly, the hopper can be opened and disassembled for easy cleaning. The power of the fan is small, the feeding speed is fast, and the cost is saved. The storage bucket size can be customized according to customer requirements.

Plastic granulation line real shot

Parameter of plastic film recycling machine

| NO. | Item | Technical data |

| 1 | Conveyor | Power:3kw Size: Length 5m , Width 0.8m Capacity:1000-1200kg/h |

| 2 | PP PE crusher | Model:1000 Power :37kw+11kw Capacity :1000kg/h |

| 3 | Belt Conveyor | Power :1.5kw Size : (L) 4m* (W) 0.6mm Capacity:800-1200kg/h |

| 4 | Automatic Feeder | Power:3kw Capacity:800-1200kg/h |

| 5 | Main Plastic Pelleting Machine | Model: LY-F300 Power:7.5kw Capacity: 800kg/h |

| 6 | Vice Plastic Pelleting Machine | Model : SL-220 Screw diameter: 220mm Screw length:L1.6m Motor:22+18.5kw |

| 7 | Plastic Pellet Bagging Machine | Model: SL-260 Screw diameter: 260mm Screw length:3.6m Motor: 110kw |

| 8 | Power:1.5kw Size :1000*1200*1100mm | Model: SL-220 Screw diameter: 220mm Screw length: L1.6m Motor:22+18.5kw |

This chart shows the general specifications of major equipment in the plastic pelletizing line. We offer machine models and types that can meet the different outputs of customers and the specific requirement of their recycling projects. The common capacities of PP PE plastic film pelletizing machine are 100kg/h, 200kg/h, 300kg/h, and 500kg/h.

FAQs of plastic film recycling machine

Can I use plastic film recycling machine to process PP and PE materials at the same time?

This plastic film-washing recycling line can be used to process multiple materials, but it can only process one material to avoid affecting the purity and quality of the final product. Moreover, the melting point of PP and PE is different, the machine can not process different kinds of plastic at the same time.

What is the power consumption of the entire production line?

The power consumption is about 500 degrees when processing one ton of material.

What is the heating method of the granulator?

Electromagnetic heating, cast aluminum heating ring, ceramic heating ring, quartz tube heating ring, etc., selected according to raw material processing needs and customer requirements.

How to make different colored plastic particles?

Add pigment when granulating, formula can be provided after the order.

How many operators do I need?

2-3 workers for a 500kg/h plastic film washing line, 3-5 workers for a 1000kg/h plastic film washing recycling line.

How big does the recycling factory have to be?

For a plastic film washing line with a capacity of 500 kg/h, the required space is 40m*15*6. For a 1000kg/h plastic recycling line, the space is 50*15*6. Our project manager will design drawings of machine placement for you.

What is the water consumption of the plastic film recycling line?

2 t for 500kg/h plastic film recycling line, 3 t for 1000kg/h washing line.

Features of the PE PP plastic film recycling line

The plastic film recycling machine can be combined into various specifications according to customer requirements. From 200KG/H-3000KG/H, our company has had successful cases. The machine’s features are a beautiful appearance, low energy consumption, high output, practicality, and reliability.

The plastic pellet making machine has different models according to customers’ requirements. The new rinsing device can be used for washing, greatly improving the production efficiency, and the cleanness of the washing material is pure, reaching the requirements of the first-level net film. It is an efficient, water-saving device.

Our company is engaged in waste plastic cleaning and plastic granulation line for more than 10 years, and can design different cleaning plans, cleaning processes, recycling planning, and site planning according to your different requirements. With our expertise, you will be rewarded with a good return on your investment.

Common materials of LDPE film recycling line

The common kinds of plastic are PE, PP, which are widely used in our daily life. Therefore, learning the main performance and use of the above raw materials of plastic film recycling machines is important.

Polyethylene (PE) has excellent processing and use properties, and is the most widely used variety in synthetic resins, and its production capacity has long ranked first among all plastic varieties. Polyethylene resins mainly include low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and high-density polyethylene (HDPE).

The density is small, the raw material is transparent and light in appearance, non-toxic and tasteless, and has high strength and elasticity. It has a high-temperature resistance of 100~120 degrees.

PP is commonly used in plastic lunch boxes, water cups, food packaging boxes, and other products.

Plastic pelletizing recycling machine for foam

Can plastic foam be recycled?

Many manufacturers recycle plastic foam, crush it with a horizontal foam crusher, and then re-bond it to make insulation layers of various insulation materials.

Another method of physical recycling is to use a plastic foam extruder, putting the plastic foam into a high-temperature environment to melt it, then extrude it, cool it, and make it into new plastic pellets, and then recycling or reusing it to make other plastic products. Our company provides a set of plastic film recycling lines, and it can help you to change the plastic foam into plastic pellets.

At present, the method of recycling through plastic foam recycling equipment is the most commonly used and the most effective resource for recycling.

The necessity of plastic film recycling machine

- Plastic production is made from petroleum, and burning plastic can produce a lot of carcinogens. The number of people getting cancer is always incredible in the places where burning plastic is. Therefore, dealing with plastic products in a proper way has no time delay.

- Plastic bags seriously pollute the marine environment and threaten marine life. Every year, 500 billion plastic bags are consumed worldwide, and most plastic products are discarded in the natural environment and eventually flow into the ocean. One million seabirds and 100,000 marine mammals die every year due to plastic pollution. Our plastic film recycling line and plastic granulator can offer people a novel method to reduce plastic waste pollution.

How to collect waste plastic before plastic granulation?

- Go to a specially designated acquisition unit to buy in bulk.

- Collect plastic scraps from plastic manufacturers.

- Organize personnel to set up receiving stations in the local place, and purchase on their own.

- Ask personnel to find waste plastic films in the local market and plastic plants by themselves.

What is the function of plastic granulator?

The function of the plastic granulating line will definitely become the new direction of waste plastics in the future which is re-granulation using a plastic granulator to avoid white pollution, incineration, and so on.

With the progress of the ages, white pollution has become increasingly serious, and waste plastics are everywhere, which wastes resources and seriously pollutes the environment. So the recycling of waste plastic provides us with a broad investment profit margin. Taking a lead must bring us good returns. The never-saturated market maximizes your investment.

How to use plastic granulator correctly?

A plastic granulator is a commonly used equipment in the plastic film recycling machine, but figuring out the effective operation method it is also a problem, which urges for a solution. Only the correct use of the plastic pellet-making machine can ensure its normal operation and ideal effect. In order to ensure the plastic pelletizer machine can fully achieve the desired effect, operators must choose the correct way of operation in the process of use.

Features of plastic pelletizer machine

The plastic pelletizing recycling machine is composed of a host extrusion machine and an auxiliary extrusion machine. The host extruder will heat the plastic films and make them into plastic melt. The main unit of the plastic granulating machine has three models, which are 125, 150, and 180. The accessories of these three models are different. The power and quantity are alternatives according to customers’ orders. The melted material is formed by wire drawing in the auxiliary extruder. There are 125, 135, and 150 models, which have different extrusion power.

Applicable industry of plastic film recycling line

- PP weaving factory: The woven bags, space bags, and non-woven fabrics produced by the PP weaving factory can be recycled and pelletized, and the recycled materials can also be used 100% in the plastic production line.

- Professional plastic recycling plant: Professional recycling plants collect waste plastic in many ways, after cleaning, the waste plastic material can be granulated into pellets by the PE film granulator again. Usually, recycling plants add additional color masterbatch or additives to change the color of the particles and improve the quality.

- Blown film production plant: The trimming waste remaining after the film blowing machine is produced (the waste from the vest bag stamping manufacturing process) can effectively recycle the entire roll of plastic film and plastic sheet. Due to the high quality, the size of recycled plastic particles is almost the same and can be directly put into the film production line for production.

Why you should choose Shuliy plastic granulator for sale

For recyclers who want to invest in a plastic film pelletizing machine, we suggest coming to our company and plant. In order to learn about the pieces of PE granulating machine better, a field trip for plastic recycling machines is important. The plastic granulator produced by our company has been purchased by many foreign customers, we can arrange for customers to visit our plant and know the machines better.

It is also a very intuitive inspection for customers. As the saying goes, seeing is believing. Customers can think through the equipment after looking at the output of the equipment, then consider the size of the equipment, such as a plastic pelletizer machine.

Global case of Shuliy plastic granulating line

Shuliy plastic granulator for sale has shipped to Kenya, Ethiopia, Uganda and other countries and received customers’ good feedback. Shuliy Group can help each customer with a best recycling solution and design a plastic pelletizing line. If you have the requirement, please contact us.

Obtain a good plastic pelletizing machine price from Shuliy

Shuliy Group is well known in the international market for our professional ability to manufacture high-quality plastic pelletizing recycling machine. Therefore, we can ensure that our customers obtain plastic film recycling machine with high-cost performance.

Meanwhile, we will provide considerable sales services to ensure our customers get the most value for their money. If you are interested, contact us right now and we will send you the plastic pelletizer machine price soon.

Sales service of plastic film recycling machine

- Pre-sales service: Provide you with project planning, process design, and develop a set of equipment that suits you; design and manufacture the plastic film recycling machine according to your special needs, and provide training for your technical operation.

- In-sale service: Precise production equipment, and accompany our customer to complete the acceptance of the plastic film pelletizing recycling machine, assist in the preparation of the installation plan, and detailed process.

- After-sales service: Shuliy Group will provide online installation instructions. If necessary, we will send our technicians to customers’ sites to guide the installation of the plastic film recycling machine, commissioning the plastic granulator to normal production, and training the operators for use and maintenance;

- Product quality: Except for wearing parts of the plastic pelletizing line, quality assurance within one year, and lifetime maintenance.

- Our company operates with integrity management and quality assurance. Welcome to consult and negotiate.

Hot Product

PET bottle flakes hot water washing tank

The hot water washing tank is suitable for…

Strand Pelletizer Machine for Rigid Plastic Recycling

Strand pelletizer machine offer recycled pelletizing technology for…

Plastic pellet cutting machine | Plastic granule cutter

This plastic pellet cutting machine is the last…

EPE Recycling Machine for Foam Pelletizing

Waste EPE foam pelletizing machine is suitable for…

Vertical type dewatering machine for waste plastic films

A vertical type dewatering machine is used for…

Plastic Sink Float Separation Washing Tank

Our plastic sink float separation washing tank uses…

Plastic Film Recycling Machine

The plastic film recycling machine is highly efficient…

Plastic Pellet Making machine

A plastic pellet making machine is a recycling…

Plastic film cold washing rinsing tank

The rinsing tank is used for rinsing the…