Raw materials of plastic film recycling production line

The common raw materials of plastic film recycling production line are PE, PP, and PVC, which are widely used in our daily life. Therefore, learning the main performance and use of the above three materials are important.

Raw materials 1: Polyethylene (PE)

Polyethylene (PE) has excellent processing and use properties, and is the most widely used variety in synthetic resins, and its production capacity has long ranked first among all plastic varieties. Polyethylene resins mainly include low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and high-density polyethylene (HDPE).

PE can be blow-molded to make various bottles, cans, industrial tanks, barrels, and other containers; injection molded to make various pots, barrels, baskets, baskets, baskets and other daily containers, daily sundries, and furniture, etc.; extrusion molding Manufacture all kinds of pipes, straps, fibers. The two most important consumer areas are pipes and films. This material is very common in the plastic film recycling line.

Raw materials 2: Polypropylene (PP)

The density of Polypropylene is small, the raw material is transparent and light in appearance, non-toxic and tasteless, and has high strength and elasticity. It has high-temperature resistance of 100~120 degrees. PP commonly used in plastic lunch boxes, water cups, food packaging boxes, and other products.

Raw materials 3: Polyvinyl chloride (PVC)

PVC is also a colorless and transparent hard material construction of downpipes, plastic steel windows, credit cards, etc. are all hard PVC. It is also common in the plastic film recycling production line. But PVC can be added with a lot of plasticizers, and then it can be made into soft PVC. Ordinary wire sheaths, disposable infusion tubes, some inflatable toys, soft curtains, transparent plastic table mats called soft glass sold in supermarkets, etc. are all soft PVC. PVC can also be colored.

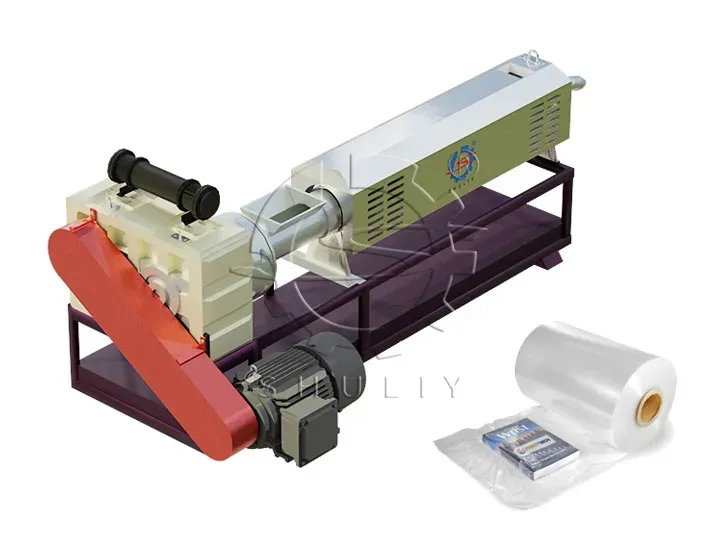

What is the difference in plastic film recycling production line?

The processing methods of plastic films of different materials are slightly different.

- Due to the characteristics of PVC material, it is best not to wash it in the process of recycling PVC plastic film. If a water washing step is necessary, the raw materials must be dried. No cleaning: plastic crusher — plastic pellet extruder — cooling tank — pellet cutting machine

- Woven bag is a very common kind of PP soft material. Some woven bags are dirty and need to be washed twice before entering the next processing step. crushing and cleaning machine — washing machine — dewatering machine — washing machine — dewatering machine — plastic granulator machine — cooling tank — pellet cutter

- There is a special type of PE plastic film, namely cling film. In supermarkets, frozen food or fresh vegetable packaging is usually covered with plastic wrap. However, this type of cling film is often affixed with a label. At this time, a paper-plastic separator is required to separate the label paper and the cling film. plastic crusher — paper-plastic separator — cleaning tank — dehydrator — plastic granulator — cooling tank — pelletizer