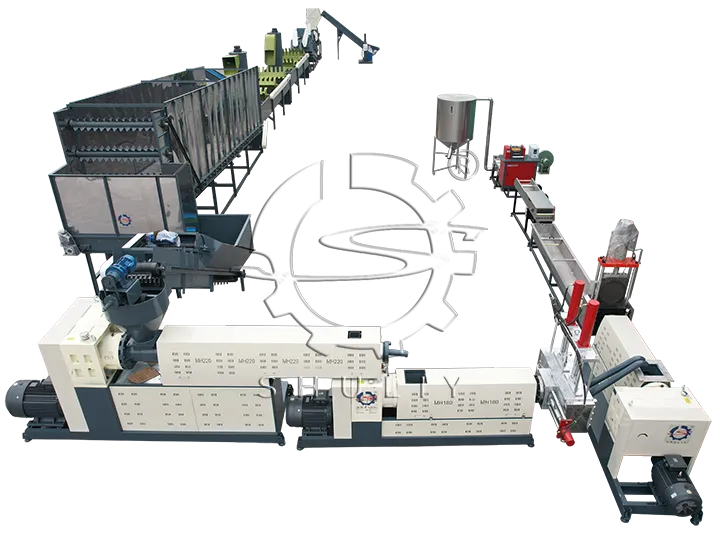

Commercial recycled plastic pellet making machine

This year’s large-scale smog weather has aroused great concern from all walks of life. Various localities have successively introduced corresponding regulations and policies to control the emission of exhaust fumes in industrial production. Plastic processing, especially waste plastic recycling and processing, all kinds of waste plastics are recycled and sorted, crushed and cleaned, sent to recycled plastic pellet making machine for high-temperature melting and filtration and extrusion, all of which have waste smoke exhaust emissions to varying degrees. A major source of secondary environmental pollution.

Large and small plastic recycling enterprises all over the country, due to the use of waste plastic pellet machine under high temperature melting conditions to produce waste smoke exhaust gas, and have not been filtered by exhaust gas treatment equipment (except the smoke machine), have been reported to be investigated and even forced to close. The situation is not uncommon. It can be predicted that with the strengthening of environmental pollution control by the state, enterprises that lack exhaust gas treatment equipment, ie, smoke removal machines, will be fined, ordered to suspend operations or even revoke business licenses.

Highlights of plastic pelletizing machine

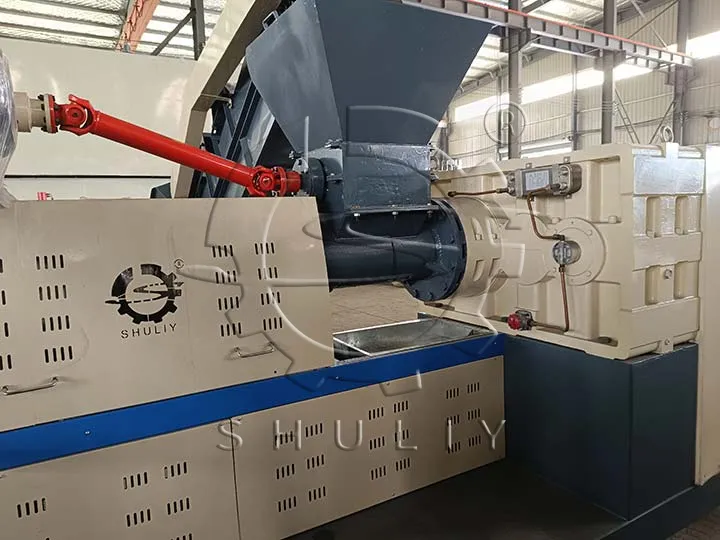

Our plastic pelletizing machine is designed with a robust double-stage screw system that ensures excellent plasticization and efficient degassing, especially when dealing with moist or contaminated materials.

The plastic pelletizing machine supports various plastic types such as PE, PP, PET, HDPE, ABS, and more, making it a versatile solution for different recycling needs. With optional hydraulic screen changers, the machine allows for continuous operation without stopping for filter replacement, significantly improving production efficiency.

The pellet size is adjustable, with a standard length of around 3mm, and the finished pellets offer high uniformity, density, and reusability. Energy consumption is optimized to approximately 400 kilowatt-hours per ton of output, and the integrated vertical and horizontal dewatering systems ensure a moisture removal rate of over 98%, contributing to high pellet quality.

Depending on the selected model, the pelletizer machine can deliver a capacity ranging from 100 kg/h up to 500 kg/h or more, providing flexible scalability for both small and large recycling operations.

Applications of plastic pelletizer

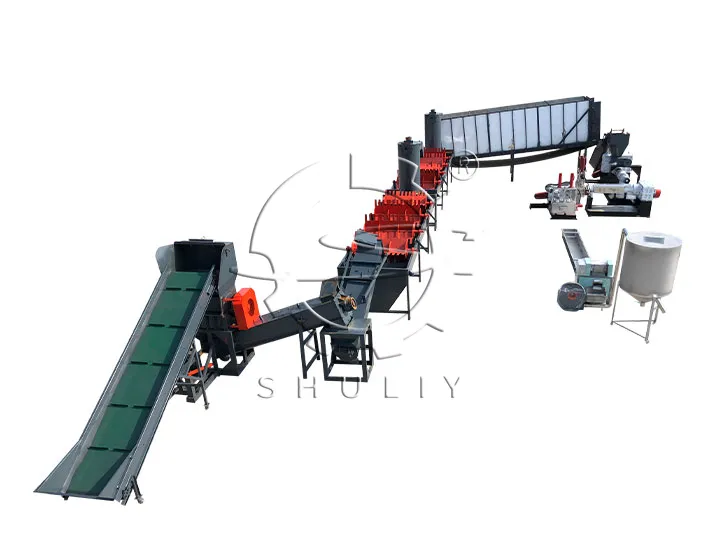

Our plastic pelletizing machine plays a vital role across various sectors of the plastic recycling and manufacturing industry. In plastic recycling plants, it transforms post-consumer waste like bottles, films, and bags into reusable plastic pellets, reducing raw material costs and environmental impact. For PET bottle recycling facilities, the machine works seamlessly with bottle crushers and washing lines to process PET flakes into clean, uniform pellets suitable for fiber production or re-blown bottles.

In film-to-pellet production lines, such as for LDPE or HDPE agricultural films, the machine efficiently handles lightweight, soft materials—often heavily contaminated—by integrating friction washers, dewatering systems, and a two-stage extrusion process to ensure high pellet quality.

In rigid plastic granulating line, injection molding and blow molding factories can recycle the injection leftover waste or factory defective materials. The waste plastic can be turned into recycled pellets. Then those plastic production factories can use these recycled pellets as raw material to produce items like containers, pipes, buckets, or packaging films, thereby lowering production costs and improving sustainability.

Additionally, our pelletizing line is frequently used in government-backed environmental projects across regions like Africa and Southeast Asia, helping municipalities and waste management companies turn local plastic waste into economic value. For startups and small recycling workshops, our compact models (100–200 kg/h) provide a cost-effective entry point to start local recycling businesses with minimal space and labor requirements.

Optional Configurations

To meet the diverse needs of different recycling materials and factory setups, our plastic pelletizing machine offers a wide range of customizable configurations:

Feeding System Options:

Choose from a screw-type force feeder or a claw-type force feeder, depending on whether you are processing soft films, rigid flakes, or bulky materials. These feeders ensure stable input and are especially effective for high-capacity plastic granulator setups.

Cutting Methods:

For pelletizing, you can select strand cutting, water ring cutter, or underwater pelletizing system. Water ring pelletizers are ideal for continuous operation with high output, while strand cutting suits small and medium-scale recycling lines.

Heating Systems:

The pelletizer extruder supports various heating options, including ceramic heaters, electromagnetic induction heating, and heating bands. Ceramic and electromagnetic heating ensure consistent temperature and energy efficiency, which is especially important in long-run plastic recycling granulator operations.

Die Head Types:

Improve filtration and reduce downtime by choosing from a hydraulic dual screen changer, hydraulic single plate screen, or a non-mesh waste-exit die head. These die heads are crucial for removing impurities, especially when processing PET bottle flakes or heavily contaminated film.

Vacuum Degassing System:

For better pellet density and reduced odor, the machine can be equipped with a vacuum degassing system. This helps eliminate moisture, oil, and volatile gases during plastic melting, resulting in stronger, higher-quality plastic pellets.

Control Panel:

Upgrade to a PLC-controlled touch screen interface for intelligent temperature control, real-time monitoring, and automatic shutdown/startup. This system simplifies operation and ensures greater safety and stability during pelletizing.

Screw & Barrel Customization:

The screw diameter and length can be tailored to your material type (e.g., LDPE film, HDPE flakes, ABS regrind). All screws are made from hardened alloy steel with superior wear resistance for long-term durability.

Recycled plastic pellet making machine

First, the equipment layout. Before the installation of the recycled plastic pellet making machine, water and electricity are mainly considered. At the same time, attention should be paid to the discharge port of the exhaust gas treatment equipment. The exhaust port should be placed at the downwind to facilitate the timely discharge of the exhaust gas. Otherwise, the dust may accumulate in the production workshop and cannot be discharged, which may affect the work of the workers, and the long-term discharge is harmful to the human body.

Second, the location of the enterprise. The address of the plastic recycling enterprise is best chosen in the industrial park. First, the industrial zone is the place where the government plans. The enterprise is convenient to enter and can receive government support, especially some policy support. Secondly, the enterprises in the industrial park are basically high-emission. Enterprises, the government will have certain emission requirements, as long as the enterprises operate within the environmental protection requirements, the government will not interfere too much.

Third, plant construction. In the production process of recycled plastic pellet making machine, it is inevitable to produce a certain amount of waste gas. When planning the plant, the exhaust gas emission problem should be fully considered. The construction of the plant is suitable for the downwind of the local wind direction, and the maximum possible avoidance and reduction of residents—pollution of the area.

The above three points are all problems that enterprises should pay attention to in the construction and production of the factory. They are the preconditions for the smooth discharge of exhaust fumes. However, some exhaust fumes are harmful and have their own position, and cannot be directly discharged into the air. This requires the company to be equipped with corresponding exhaust gas treatment equipment. The exhaust gas is first filtered through the exhaust gas treatment equipment to achieve non-polluting standards before being discharged.