PET Plastic Bottle Recycling Machine

PET recycling machines | Plastic bottle washing and crushing plant

PET Plastic Bottle Recycling Machine

PET recycling machines | Plastic bottle washing and crushing plant

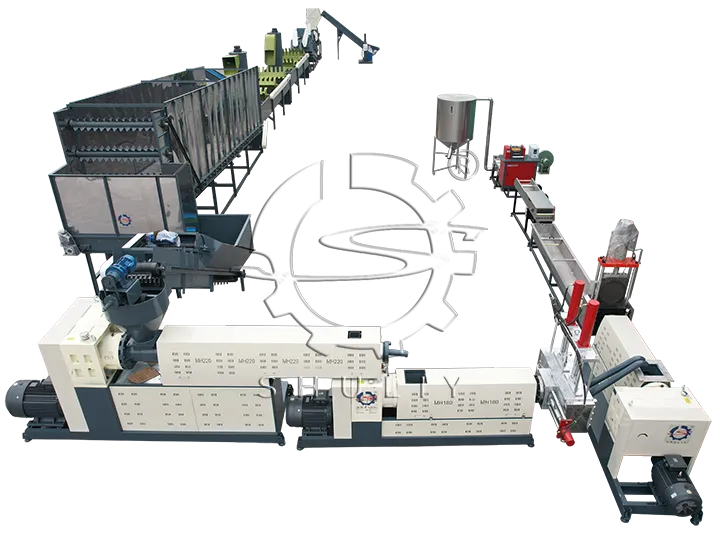

Our complete PET bottle recycling line is an ideal solution for anyone looking to start or improve their plastic bottle recycling business. The final products are clean PET flakes which can be sold at a good price.

Shuliy Machinery has manufactured PET bottle washing line machines for years and exported plastic bottle recycling machines all over the world, such as Nigeria, Saudi Arabia, Congo, Zambia, and Mozambique. Welcome to consult the plastic bottle recycling machine and visit our recycling plant!

Introduction of plastic bottle recycling machine

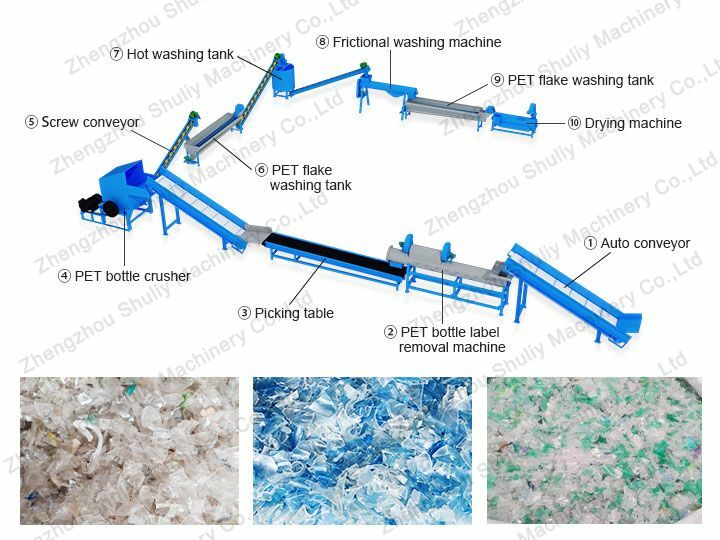

Plastic bottle recycling machines mainly includes plastic bottle label removal machine, plastic crusher, high-temperature washing barrel, rubbing washing machine, dewatering machine, etc.

This PET bottle washing line is mainly used to recycle waste mineral water bottles, cola bottles, plastic bottles made of PET. Shuliy Group can match different PET bottle washing plant, design factories, and calculate factory areas according to customers’ different production needs, uses, and raw materials.

Recycling steps: removing bottle labels — removing bottle trademarks — crushing — cleaning — drying — storage

500kg/h PET bottle recycling machines display

1000kg plastic bottle recycling machine design

Raw material & final products of plastic bottle washing plant

PET plastic bottles are widely used for packaging carbonated beverages, mineral water, fruit juice, and other kinds of beverages, they are the most used beverage packaging nowadays. More than that, PET is also widely used in food, chemical, pharmaceutical packaging, and many other fields. 650 billion PET bottles were produced and sold globally, and the increasing speed is still rising.

Working video of PET recycling machines

3D video of PET bottle recycle machine

Introduction of PET bottle washing line

Step 1: Convey and picking (auto conveyor)

The picking table is made of belt conveyor steel frame structure, PVC belt with scraper, bend pulley, driving pulley, as well as adjustable speed motor, etc. It can be used in different fields, here it is the necessary equipment in plastic bottle recycling line.

Due to PET and PP PE are different materials, the processing of treatment is different, in order to increase the purity of final PET flakes, it is better to select the different material first.

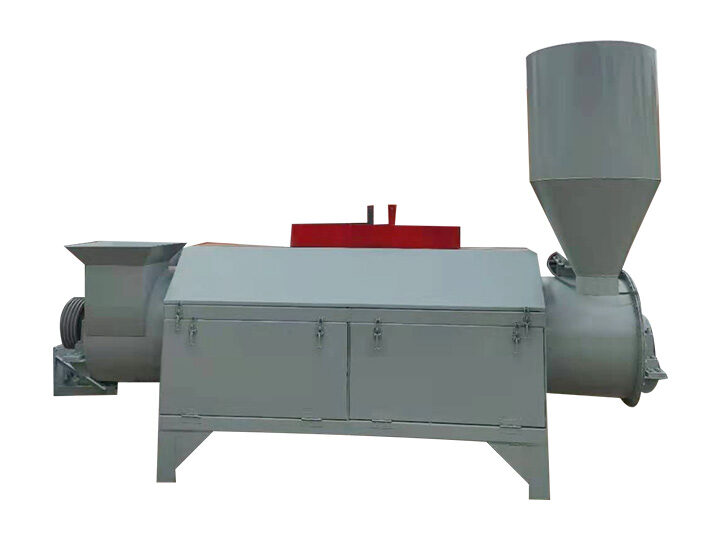

Step 2: Remove trademark (plastic bottle de-labeling machine)

PET bottles label removing machine is professional in removing PET bottles label or water bottles label, it instead of people removing the label, to meet the big capacity requirements of the plastic bottle recycling line. By adjusting the blades, it can use for removing different size bottles.

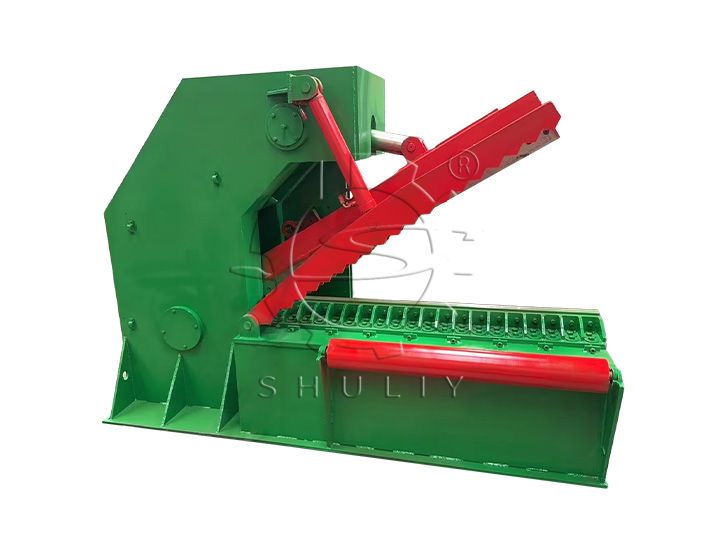

Step 3: Crushing (plastic crusher)

The plastic crusher is used for crushing PET bottles, PVC, etc, it can crush the raw material into small flakes to recycle the waste plastic. The PET crusher is suitable for the plastic bottle recycling line.

Step 4: Cleaning (washing tank)

The washing tank separates PP or PE bottle caps from PET flakes, and also can clean the plastic flakes for the first time.

Step 5: Cleaning with hot water(hot water washing tank)

The hot water washing tank is an upper open structure with functions of automatic temperature control, heat preservation, and stirring. Which also has the advantages of fast heat transfer, large temperature difference, and convenient cleaning.

Widely used in waste plastics and other industries as heating, cleaning treatment. The hot water washing tank is especially suitable for small, medium, and large cleaning chemical fiber factories. And can adopt a completely closed structure according to technological demand.

Step 6: Friction cleaning (friction machine)

As one kind of plastic bottle recycling machine, a high-speed friction machine has its own unique function and advantage in the use of cleaning equipment.

The high-speed rotating screw allows the material to be fully rubbed with water, and the impurities (soil, sand, leaves, paper pulp) on the surface of the material are separated, and the dirty goods are washed with clean water. Unique water spraying design and high-speed running screw ensure an excellent cleaning effect.

Step 7: Washing and separating again (washing tank)

The washing tank is for washing and separating PP PE from PET again. Some materials need to be washed multiple times. Due to customers’ requirements, broken plastic needs to be cleaned four times in the plastic bottle recycling line. In this operation, the plastic pieces would be separated and cleaned thoroughly, all impurities would be removed.

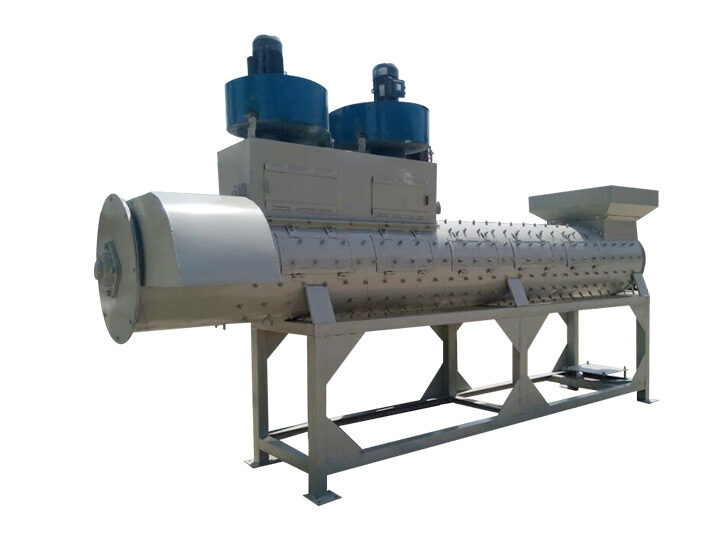

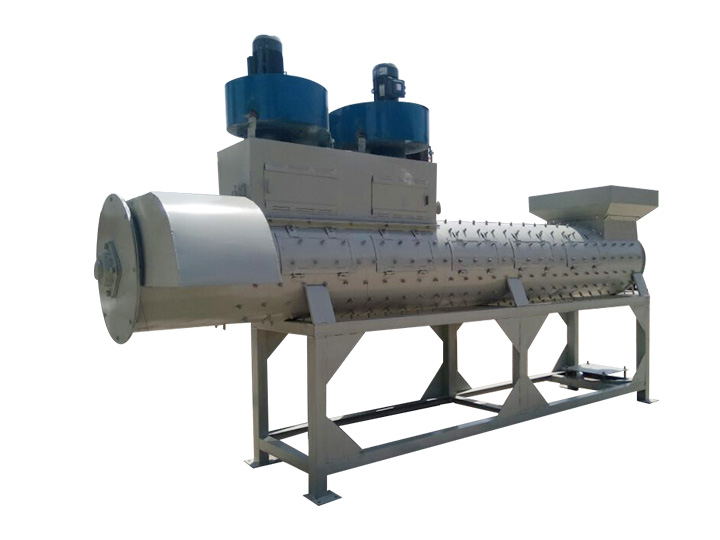

step 8: Drying and dehydration (dehydrator machine)

The plastic dehydrator machine is mainly used for the dehydration function of PP pellets so that the finished product can meet the storage requirements.

The wet PP particles are gradually raised by the auger of the plastic dehydrator machine, and more water is extracted by the principle of high-speed rotation. The machine can automatically feed and discharge, with no need for manual operation, and greatly improve work efficiency.

Step 9: Storage (storage bin)

Dried PET pellets were conveyed by the fan. Stock bin and packing machines not only can store final PET pellets but only can separate different materials. Stainless steel stock bin and packing machine plays important role in the transportation and packing of bags.

Plastic drying pipe for higher flake requirement

To achieve lower moisture content in the final PET flakes, especially for high-grade or food-grade applications, our recycling line can be equipped with an optional plastic drying pipe system. This stainless-steel drying pipe provides fast, uniform moisture reduction after washing and dewatering, helping reduce the final moisture level to below 0.5%.

Video 1: plastic bottle crushing and washing plant

Recycled PET flakes quality

Pellet Sizes: Recycled PET flakes are often made into different pellet sizes depending on the specific requirements of the production. Common pellet sizes are usually around 2-3 centimeters.

Color: The color of PET recycled flakes can vary depending on the source of the raw material and the treatment process. Common colors include transparent, blue, green, etc. The exact color is determined by the customer’s raw material.

No Impurities: Recycled PET pellets should contain the lowest possible level of impurities. Impurities can be from other plastics that were not completely removed during the recycling process, grease, color, etc.

Moisture: PET is a moisture-sensitive plastic, so recycled PET flakes usually needs to be dried, and our recycling lines process PET flakes with less than 1% moisture.

Plastic bottle recycle machine successful projects

Machine recycling plastic bottles shipped to Nigeria successfully

One client from Nigeria asked us for machine recycling plastic bottles, he is a purchaser of a professional recycling company. The company needs their recycling equipment to be painted green. Therefor, our manufacturing plant customized the following machines for them.

If you are interested in the project, welcome to read this case: Machine recycling plastic bottles for Nigerian recycling company.

Plastic bottle recycling machine in Nigeria

Shuliy waste plastic bottle recycling machines were ordered by our Nigerian customer. Their recycle materials are waste plastic bottles. If interested, you can get more details and video on this article: PET bottle recycling plant in Nigeria.

Washing machines of PET bottle washing plant

The necessary washing machines for cleaning PET flakes are a washing tank, hot water washing tank, and frictional washing machine. In fact, the PET washing machines are adjustable to choose from, people with a low budget can choose these three machines to wash their plastic flakes.

But if the waste plastic bottle is too dirty or the plant would like to use more washing equipment to ensure the plastic’s cleanliness, the number of washing tanks, hot water washing machines, and frictional washing machines can increase to two or three.

PET bottle washing line

Our plastic bottle recycling line can also adjust the kind of washing machine according to the customer’s order and the raw material. The whole washing step includes three washing machines, which are two washing tanks, a hot water washing tank, and a friction machine. The following video shows the customized plastic bottle recycling line which uses only one piece of washing equipment.

How are recycled plastic bottles reused?

Many people may wonder where recycled plastic water bottles have gone. In other words, many people know that plastic bottles can be recycled, but they don’t know what they can do after recycling.

- Firstly, recycled plastic water bottles can be used to make textile materials, such as polyester, RPET cloth, etc., and then made into gloves, mattresses, etc.

- Secondly, recycled plastic PET bottles can be granulated into pellets, which can be made into various toys, buckets, and other daily supplies.

- After multiple processing or prolonged UV irradiation, plastics will cause problems such as aging and viscosity reduction. This waste plastic can also be recycled for RDF power generation. Due to the high heat value of plastic, the power generation effect is very ideal.

Read more: What can recycled PET flakes do?

Prospects of the plastic bottle recycling business

A large part of the production of plastics depends on petroleum. The recycling of plastics is the recycling and utilization of petroleum resources.

From a macro perspective, the prospects of the plastic water bottle recycling industry are very optimistic. At present, the main recycling industries include waste metal recycling, waste paper recycling, waste rubber recycling, and waste plastic recycling. The reuse rate of waste metal can reach 70-80%, the waste rubber can reach 47%, and the waste paper 20-30%. However, the reuse rate for plastic is less than 30%.

Therefore, the recycling market of waste plastics is still very broad, and the plastic bottle recycling line is also very popular and practical. Combined with the global attention to environmental protection, resource conservation, and other issues, the requirements of plastic bottle recycle machines will keep increasing, and the development potential of the plastic recycling industry will only grow.

Profit of plastic bottle recycling machine

The main methods of dealing with plastic waste mainly include incineration, disposal in a landfill, and recycling. Plastic waste recycling maybe not be a very profitable business in many people’s opinion. Exactly, one plastic bottle has very low value, however, in the big cities, millions of waste mineral water bottles will be produced by people at least, one-ton mineral water bottle probably has 60 thousand plastic bottles, which can make a profit of about 300 dollars.

On the surface, the plastic bottle recycling line is a business with low profit, in fact, if you have a stable supply, comprehensive knowledge of plastic, and a team, plastic recycling is a profitable business for you.

FAQs of plastic bottle recycling machines

What is the output of this PET bottle washing plant?

Generally speaking, the production range of this production line is 500-3000 kg per hour. The maximum output can reach more than 6 tons per hour.

What are the electricity and water consumption rates for the line?

We design our systems with energy efficiency in mind. For any proposed rPET flakes production line, we provide a detailed report on the total installed power and estimated consumption of electricity and water per ton of output. Furthermore, our systems can be designed with a water circulation and filtration system to significantly reduce fresh water consumption, further lowering your daily operational costs.

Is it necessary to wash the PET flakes four times?

It depends on your raw materials, if your plastic bottles are not very dirty, it is possible to clean them less than four times.

Is a PET recycling plant truly profitable, and what is the estimated Return on Investment (ROI)?

The profitability of a PET recycling plant is excellent. However, your ROI is influenced by three local variables: the procurement cost of waste bottles, your operational costs (electricity, water, labor), and most importantly, the selling price of your rPET flakes. Our systems, especially those equipped with comprehensive hot washing and purification stages, are engineered to maximize your product’s market value. High-quality clean flakes can sell for 15-30% more per ton than standard cold-washed flakes. Based on our clients’ experiences, the investment payback period is typically between 1.5 to 3 years. We can assist you with a preliminary profitability analysis for your specific region.

Do you provide installation and training? My workers have no prior experience.

Yes, this is a core part of our service and a key advantage. We dispatch experienced engineers to your site to supervise the complete installation, commission the equipment, and provide comprehensive, hands-on training for your operators and maintenance staff. We continue until the line is running smoothly and producing qualified products. We deliver a fully operational system, not just a set of machines.

How to choose PET recycling machines with a low budget?

Because the cleanliness of plastic bottles is different, the washing equipment they need is different too. A washing tank, a hot water washing tank, and a frictional machine are necessary for recycling PET bottles, if one has a low budget, he can choose these three machines at least.

But if he has a high budget, he can choose more three PET recycling machines, for example, one washing machine, two or three hot water washing machines, two frictional machines. Machines in different numbers will provide different effects. More cleaning machines can wash waste PET flakes cleaner, which also has a higher price.

Why plastic bottle recycling machines become more and more popular?

- Many waste PET plastic bottles are produced every day, which causes great pollution to the environment. Recycling waste is good for protecting the environment.

- Turn waste plastic bottles into treasures, it has widely used. People’s education level has improved hugely, more and more people started to realize the importance of environmental protection.

- Save resources and promote the development of the industry. Recycling plastic waste can help plants save resources and costs, the leftovers of production can be reused, it is good for business.

Client feedback on the plastic bottle recycling machine

Our customers bought our plastic recycling equipment, and they have a very high comment of our plastic bottle recycling machine, and already put them into use. Here are some photos of their visit to our company and factory. We entertained them warmly, then they expressed their satisfaction to us and started their own plastic recycling business. Shuliy machinery welcomes clients to visit our company and factory.

Our service of PET bottle washing line

- Our delivery time is one month, from the receipt of an order to the goods arriving at the port.

- The goods will be dispatched on time, and customers can check the logistics information during the transportation.

- When customers receive the goods, we will offer plastic bottle recycling machine instructions and an installment video. We can also offer a live stream or organize our engineer to your plant to instruct.

- Except for wearing parts, quality assurance within one year, and lifetime maintenance.

- Our company’s integrity management, and quality assurance,welcome to consult and negotiate.

Hot Product

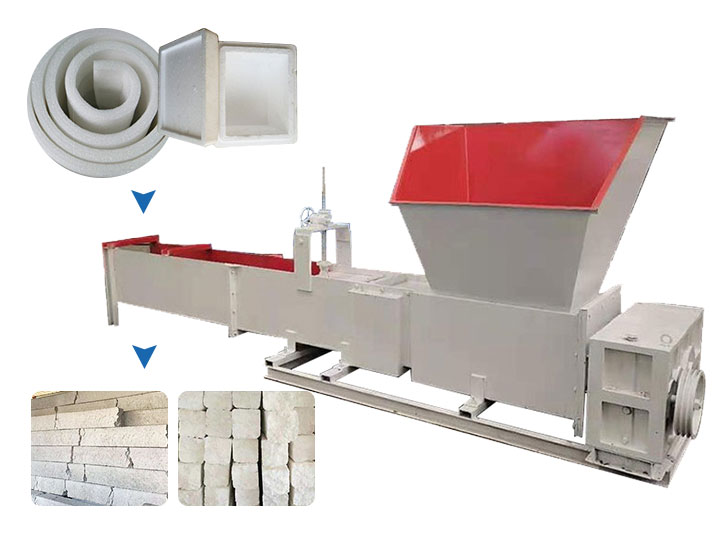

Vertical EPS foam compactor | Styrofoam recycling densifier

Vertical EPS foam compactor is one of the…

Belt conveyor | Plastic bottle sorting table

Structure of belt conveyor The belt sorting table…

Waste Plastic Crusher for PP LDPE HDPE Recycling

A waste plastic crusher cuts plastic materials into…

EPS/Styrofoam Densifier Hot Melting Machine

Descriptions of the styrofoam densifier The styrofoam densifier…

PET bottle label remover recycling machine

PET bottle label remover is indispensable for plastic…

Automatic feeding machine | Forced feeder for plastic recycling

This automatic feeding machine is designed to simulate…

Paraffin wax granule machine|Industrial paraffin pelletizer

The paraffin wax granule machine utilizes the low…

OTR Tire Cutting Machine for 1400-4000mm Tires

The OTC-4000 is a specialized OTR tire cutting…

Plastic Film Recycling Machine

The plastic film recycling machine is highly efficient…