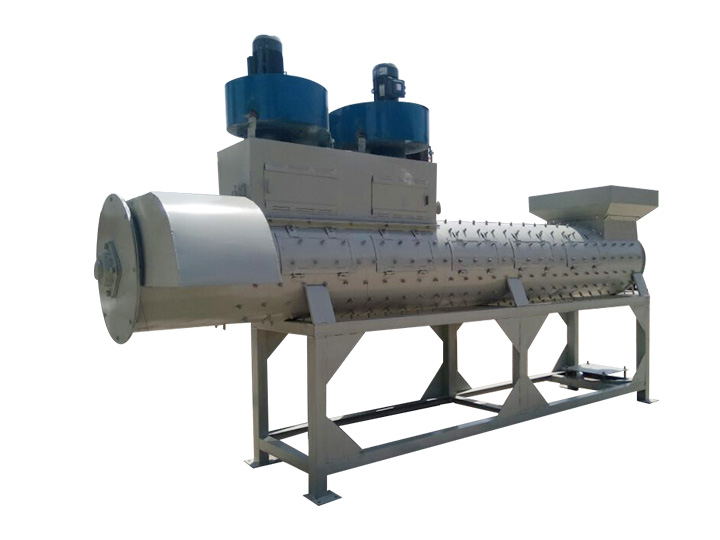

摩擦洗浄機の作業プロセス

プラスチック洗浄機器の一種として、高速摩擦洗浄機は洗浄機器の使用において独自の機能と利点を持っています。

プラスチックリサイクルラインでは、高速回転スクリューが材料を水と完全に擦り合わせ、材料の表面にある不純物(土、砂、葉、紙パルプ)を分離し、汚れた物を清水で洗浄します。独自の水噴霧設計と高速運転スクリューが優れた洗浄効果を確保します。

プラスチック摩擦洗浄機の機能

1. 機械的摩擦を使用して、ボトルフレーク上の油、接着剤、紙パルプ、その他の不純物を除去します。

2. 動水の洗浄により、フィルターを通して沈殿物やパルプを排出し、非常に理想的な洗浄効果を達成します。

3. 汚染の程度に応じて材料の洗浄時間を制御します。

スクラビングマシンの構造

PETボトルの摩擦洗浄機の本体は、主機、モーター、フットフレーム、水の入口、供給入口、排出穴などで構成されています。本体の底部には細かいメッシュフィルターがあり、上部には外部水の入口があります。材料は供給入口から投入され、高速回転するスクリューによって材料が流れる水と完全に擦れ合い、材料を完全に洗浄することができます。

摩擦式洗濯機の特徴

摩擦式洗濯機は廃プラスチックの洗浄に使用されます。小さな占有面積、簡単な操作、高い生産性という利点があります。プラスチック洗浄ラインの補助設備として使用できます。

摩擦式洗濯機のパラメータ

| アイテム名 | プラスチック製摩擦式洗濯機 |

| 容量 | 400-600kg/h |

| パワー | 7.5kw/380-v/50hz/3ph |

| 洗浄チューブの直径 | 0.4m |

| 給餌入口 | 40*40cm |

| 機械のサイズ | 4.1*0.6*1.4m |

| 機械の重量 | 560kg |

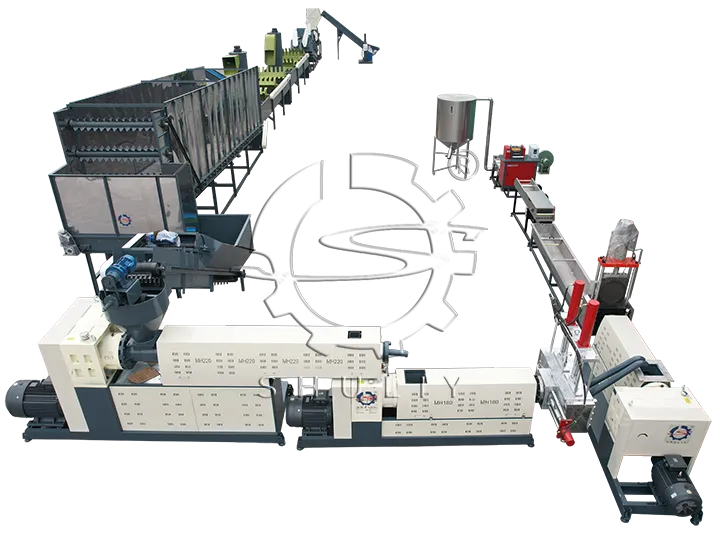

関連するPETボトル洗浄ライン

全体のプラスチックボトルリサイクルプラントには、PETボトルラベル除去機、プラスチッククラッシャー、シンクフロート分離洗浄タンク、自動コンベヤーなどが含まれています。私たちのPETリサイクルプラントはほとんどのプロジェクトに最適なソリューションです。ただし、特別な要求に応じたカスタマイズソリューションも提供されています。

ホット商品

手動粉体コーティングブース

手動粉体コーティングブースは小型です…

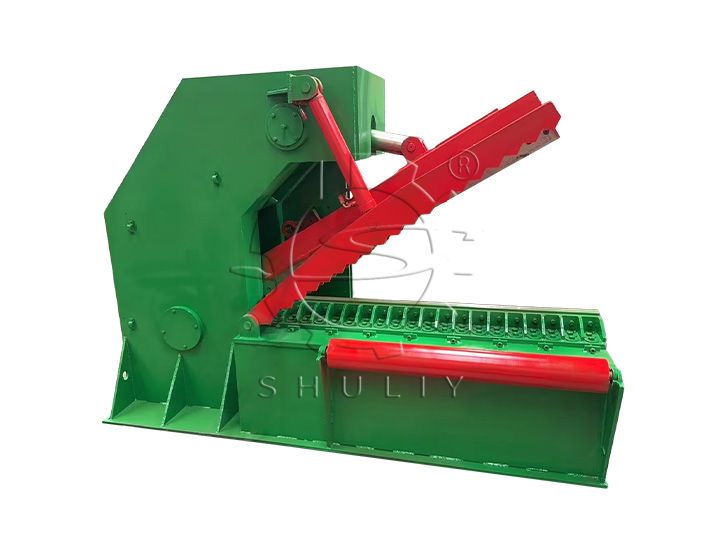

1400-4000mmタイヤ用OTRタイヤカッティングマシン

OTC-4000は、特殊なOTRタイヤカッティング…

プラスチックフィルムリサイクル機

プラスチックフィルムリサイクル機は非常に効率的です…

PETボトルリサイクル用トロンメル

このトロンメルはPETボトルリサイクル用です…

PETプラスチックボトルリサイクル機

私たちの完全なPETボトルリサイクルラインは…

プラスチックシンクフロート分離洗浄タンク

私たちのプラスチックシンクフロート分離洗浄タンクは…

廃プラスチックフィルム用の縦型脱水機

垂直型脱水機は…に使用されます。

PETボトルラベル除去リサイクル機

PETボトルのラベル除去機はプラスチックにとって不可欠です…

自動給餌機 | プラスチックリサイクル用強制フィーダー

この自動給餌機はシミュレーションするように設計されています…