Purity – Der entscheidende Faktor, der Ihre ACP-Recycling-Gewinne bestimmt

In the ACP recycling industry, one of the first questions we are asked is: “What is the purity of the separated aluminum and plastic?” This is a critical question, as it is directly tied to your final sales revenue.

At Shuliy, we believe in giving you a responsible answer, not just an empty number. The final purity of the materials is not determined by the machine alone; it is a comprehensive result influenced by several factors:

- Raw Material Quality: Are your scrap panels from building facades or advertising signs? Are they covered in significant amounts of dirt, cement, or glue? Cleaner, more uniform panels will naturally yield a higher purity.

- Operator Proficiency: An experienced operator can precisely adjust the heating temperature and stripping speed based on the thickness and condition of the panels. This is crucial for achieving the best separation. Incorrect temperatures can lead to plastic adhesion or incomplete separation.

- Equipment Maintenance: Keeping the rollers clean and sharp is fundamental to achieving high-purity separation.

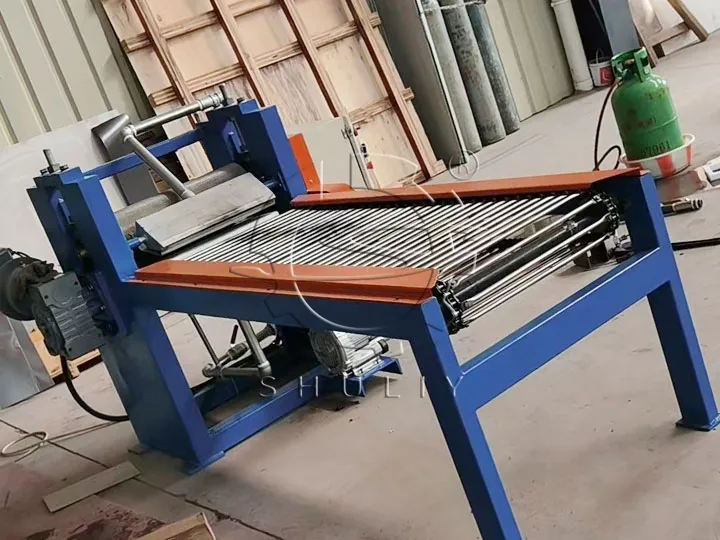

Our SL-Series ACP Recycling Machine, with its heat-treated, high-grip rollers and precise temperature control system, provides a solid technical foundation for achieving high purity. But we believe a true partnership means helping you solve challenges across your entire workflow.

Want to know what purity you can achieve with your specific raw materials? Contact our technical consultants today. Send us photos or a video of your materials, and we will provide you with a free, professional purity assessment and profit forecast.