Von Abfall zu Reichtum: Der Erfolg einer saudischen Anlage mit einer Styropor-Granuliermaschine

Weltweit verlassen sich Industrien von der Fertigung bis zur Logistik auf EPS-Schaum (Styropor) für seine hervorragende Polsterung und Isolierung. Diese Abhängigkeit schafft jedoch eine universelle Herausforderung: Was tun mit dem sperrigen, leichten Abfall danach? Das ist nicht nur ein Umweltproblem; es ist eine erhebliche Belastung für Lager- und Betriebskosten.

Aber für ein Recyclingwerk in Saudi-Arabien wurde diese Herausforderung zu einer kraftvollen Wachstumschance. Durch eine strategische Investition in Technologie verwandelten sie ein lästiges Problem erfolgreich in einen neuen Einnahmefluss. Dieser Artikel erläutert, wie sie es geschafft haben.

Die Herausforderung: Wenn Styropor zum Engpass wird

Für diese saudi-arabische Recyclinganlage kam das Unternehmenswachstum mit einem zunehmenden Problem. Die riesigen Mengen an Schrott-EPS-Schaum, die sie sammelten, wurden zu einem erheblichen betrieblichen Engpass, der ihren Fortschritt behinderte.

Schmerzpunkt 1: Steigende Lager- und Logistikkosten

Der Werkleiter beschrieb ein drängendes Dilemma: "weiße Berge" von EPS-Schaum nahmen wertvollen Lagerplatz in Anspruch, der für höherwertige Materialien hätte genutzt werden können. Der Transport dieses federleichten, aber voluminösen Abfalls war ineffizient. Lastwagen transportierten im Wesentlichen "Luft", was zu unverhältnismäßig hohen Logistikkosten für sehr wenig Materialgewicht führte.

Schmerzpunkt 2: Geringer Wert und schwierige Entsorgung

Im rohen, unverarbeiteten Zustand hat Schrott-EPS-Schaum einen minimalen Marktwert. Der Verkauf brachte kaum Gewinn, und in einigen Fällen mussten sie für die Entsorgung bezahlen. Es war ein reines Kostenzentrum. Das Management wusste, dass es ohne eine effektive Möglichkeit, den physikalischen Zustand des Schaums zu transformieren, eine Verbindlichkeit in ihrer Bilanz bleiben würde.

Die Lösung: Ein maßgeschneidertes Styropor-Granulatorsystem

Nach einer gründlichen Bewertung ihrer Schwachstellen lieferten wir eine integrierte Lösung mit einem Styropor-Zerkleinerer und einem Styropor-Granulator. Das Ziel war einfach: Abfälle aus EPS von geringem Wert direkt in ihrem Werk in hochdichte, hochwertige recycelte Granulate zu verwandeln.

Schritt 1: Hoch effizientes Zerkleinern mit dem SL-800 Zerkleinerer

Der Prozess beginnt mit der Volumenreduzierung an der Quelle. Die Arbeiter füttern große Blöcke von EPS-Schaum in den SL-800 Styroporzerkleinerer. Die Hochgeschwindigkeitsklingen der Maschine zerkleinern den Schaum sofort in kleine, handhabbare Stücke und bereiten ihn für die nächste Phase vor, wodurch sofort drastische Platzersparnisse erzielt werden.

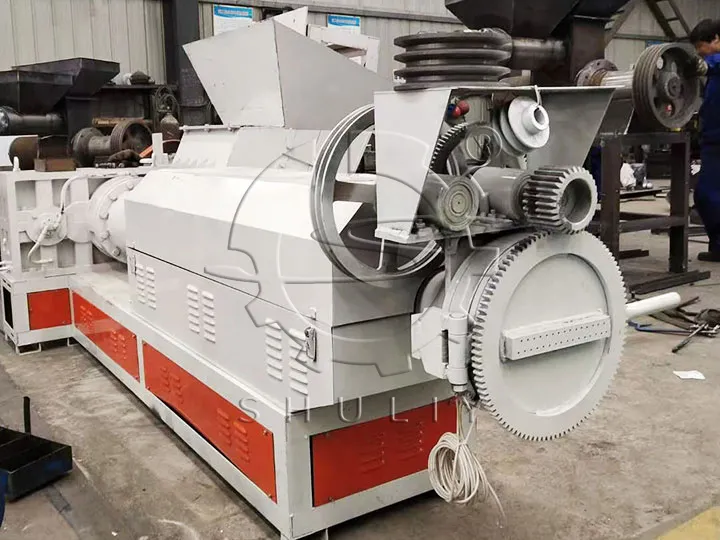

Schritt 2: Schmelzen und Extrusion mit der SL-270 + SL-150 Pelletisiermaschine

Der zerkleinerte Schaum wird dann in das Herzstück der Lösung gefüttert: unsere zweistufige SL-270 + SL-150 Styropor-Pelletisiermaschine.

- Der SL-270-Hauptextruder schmilzt den Schaum, plastifiziert ihn und entfernt Gase.

- Das geschmolzene Material gelangt dann zum SL-150-Zweiextruder für weitere Plastifizierung und Filtrierung, um sicherzustellen, dass Verunreinigungen entfernt werden und das Material perfekt entgast ist.

- Schließlich wird der gereinigte geschmolzene Kunststoff durch einen Düsenkopf extrudiert, abgekühlt und in gleichmäßige, dichte EPS-Pellets geschnitten.

Dieses zweistufige Design ist entscheidend für die Herstellung von Pellets mit überlegener Reinheit und Dichte im Vergleich zu einstufigen Maschinen.

Fazit: Ihr EPS-Abfall ist Ihre nächste Wachstumschance

Der Erfolg dieses saudi-arabischen EPS-Recyclingwerks demonstriert eine klare Wahrheit: EPS-Schaumabfall ist kein unlösbares Problem. Mit der richtigen Technologie ist es eine Geschäftsmöglichkeit mit hohem Potenzial, die darauf wartet, erschlossen zu werden. Ihr Weg war einfach: den Schmerzpunkt identifizieren -> eine professionelle, integrierte Lösung implementieren -> erhebliche finanzielle, betriebliche und Markenbelohnungen ernten.

Steht Ihre Anlage vor einer ähnlichen Herausforderung mit EPS-Abfällen? Es ist an der Zeit, diese nicht als Problem, das gelöst werden muss, sondern als Chance zu sehen, die ergriffen werden muss. Kontaktieren Sie uns und erfahren Sie mehr über eine komplette EPS-Recyclinglinie.