Машина для резки боковой стенки шины

Машина для резки боковой стенки шины

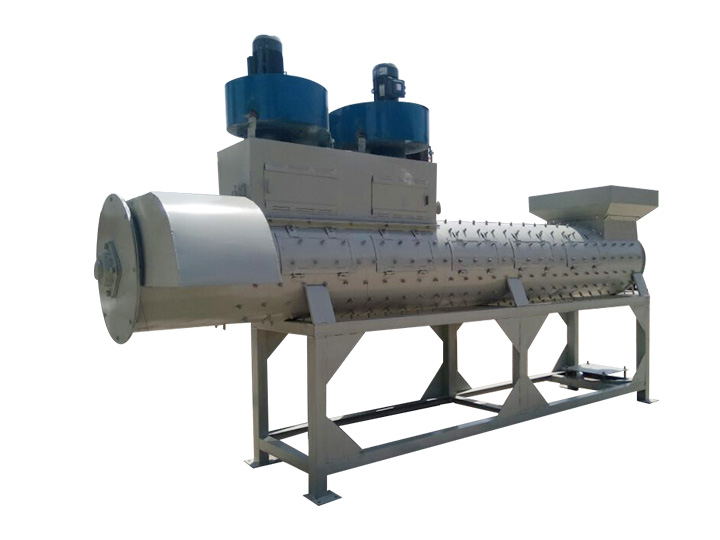

Машина для резки боковин шин TCC-1250 — это базовое предварительное оборудование, предназначенное для выполнения одной важной задачи: аккуратно отделить прочное, усиленное стальной проволокой обод от боковины и протектора шины. Весь цикл выполняется эффективно за примерно 90 секунд.

Кругорез для боковин шин для вашего перерабатывающего завода

Для малых или средних предприятий по переработке шин этот начальный шаг дает три немедленных и измеримых преимущества:

- Резкое снижение затрат: данные клиентов постоянно показывают, что предварительная обработка с помощью TCC-1250 увеличивает срок службы режущих ножей в 2-3 раза. Это напрямую снижает ваши основные расходы на обслуживание и время простоя.

- Увеличенная пропускная способность: удаляя самый стойкий компонент в первую очередь, значительно снижается нагрузка на шредер. Это может увеличить общую производительность на 20-30% без необходимости более мощного шредера.

- Новый источник дохода: аккуратно извлечённое стальное кольцо обода превращается из загрязнителя в товар для продажи, обеспечивая дополнительный и надёжный источник дохода от каждой переработанной шины.

Ключевые особенности машины для резки боковин шин Shuliy

Ценность TCC-1250 определяется точными, проверяемыми данными, а не расплывчатыми маркетинговыми терминами. 1.

Оптимизированный диапазон обработки для стандартных шин: Рабочий диаметр: ∮650 мм – ∮1200 мм. Эта машина точно настроена для обработки большинства легковых и грузовых шин. Как специализированный резак боковин грузовых шин, она обеспечивает возможность переработки наиболее распространённых шин без необходимости инвестировать в излишне мощное оборудование. Это идеальный ободорез для стандартных операций переработки шин.

Измеримая производительность для полуавтоматических линий: Производительность: стабильно 40 шин в час. Эта мощность идеально подходит для подачи на полуавтоматическую линию, обеспечивая равномерный поток работы без узких мест. За стандартную 8-часовую смену можно обработать более 320 шин, что делает её самым надёжным резаком боковин шин в своём классе.

Высокопрочные сплавные ножи для максимальной работоспособности: Материал ножа: HSS (Высокоскоростная сталь). С твердостью превышающей HRC60, эти ножи рассчитаны на долгий срок службы. Они предназначены для обработки более 2000 тонн шин до необходимости первой заточки. Как производитель высококачественных резаков для ободных колец шин, мы делаем упор на работоспособность и низкие долгосрочные издержки для наших клиентов.

Технические характеристики машины для резки боковин шин

| Параметр | Данные |

|---|---|

| Модель | TCC-1250 |

| Общая мощность | 4.75 кВт (4 кВт + 0.75 кВт) |

| Вместимость | 40 шт./ч |

| Диапазон работы | ∮650 мм – 1200 мм |

| Рекомендуемые типы шин | Стандартные легковые и грузовые шины |

| Время цикла | Приблизительно 90 секунд |

| Материал ножа | HSS (Высокоскоростная сталь) |

| Система блокировки | [Дополнительно] |

| Размеры (ДШВ) | 1.8м * 1.3м * 1.6м |

| Вес | 650 кг |

Идеальные области применения: для растущего бизнеса

Наши преимущества — в идеальной адаптации к малым и средним предприятиям, стремящимся к прибыльности и эффективности.

- Ядро полуавтоматической линии: это идеальное применение для TCC-1250. Он служит отправной точкой для высокодоходной модульной производственной линии. Типичный рабочий процесс включает в себя машину для резки боковин шин, которая подает материал к резаку для шинных полос, за которым следует блокорез. Эта полная установка образует основу полуавтоматическая линия переработки шин, позволяя при этом низкие начальные инвестиции с возможностью масштабируемого роста.

- Обновление существующих мастерских: для предприятий, уже использующих шредеры, но сталкивающихся с высокими затратами на обслуживание, TCC-1250 — идеальное дополнение. Интегрируя этот резак для ободных колец шин на входе, вы сразу защищаете свои инвестиции, снижаете операционные расходы и увеличиваете общий выход текущего оборудования.

Горячий продукт

Троммель для переработки ПЭТ-бутылок

Этот троммель для переработки ПЭТ-бутылок в основном…

Пионерный гранулятор для переработки пластиковых отходов с водяным кольцом

Благодаря преимуществам водяного кольца…

Станок для горячей стирки фракций ПЭТ-бутылок

Система горячего водяного мытья подходит для…

Машина для резки пластиковых гранул | Резак для пластиковых гранул

Эта машина для резки пластиковых гранул является последней…

Конвейер с подъемным поясом | Наклонный транспортный механизм

Конвейер с подъемным ремнем - это необходимая машина…

Машина для упаковки пластиковых гранул | Упаковочная машина

Отходы пластика необходимо полностью упаковать после переработки…

Горизонтальный шредер для стирофома

Горизонтальная дробилка для стирофома в основном используется для…

Машина для удаления этикеток с ПЭТ-бутылок для переработки

Удалитель этикеток для ПЭТ-бутылок незаменим для переработки пластиковых…

Автоматическая линия по производству резиновой порошковой продукции

Автоматическая линия по производству резинового порошка используется…