Shuliy SL-Series ACP Recycling Machine

Scrap Aluminum Composite Panels (ACP) from construction and signage industries represent a significant waste challenge. However, locked within these panels are valuable aluminum and plastic resources.

At Shuliy, we provide the ACP Recycling Machine to turn this waste into a high-return revenue stream. This guide provides an in-depth look at the Shuliy SL-Series, a machine designed to efficiently separate these materials and maximize your profitability.

How Our ACP Delaminating Technology Works

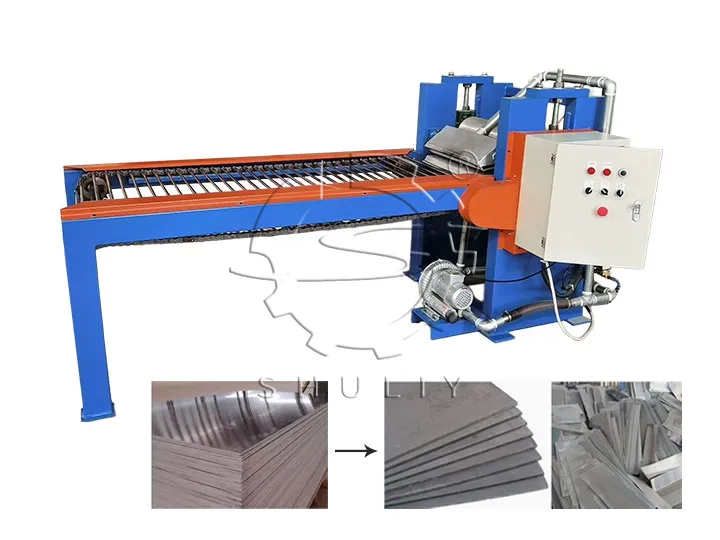

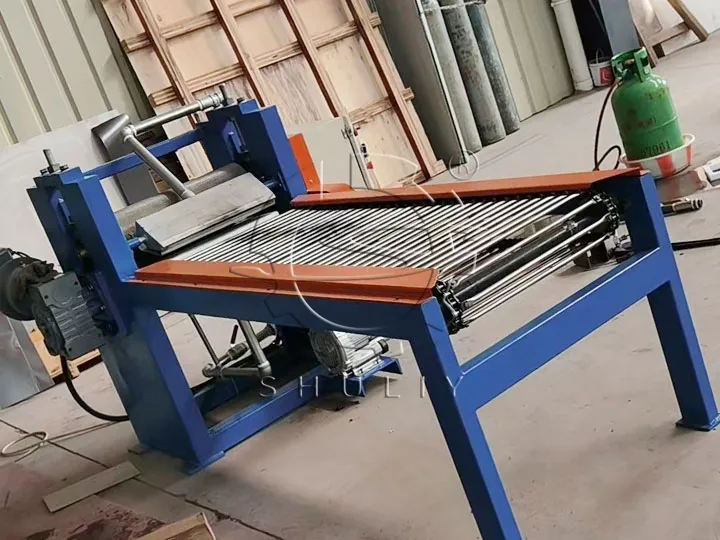

The core of our process is a highly efficient, two-stage thermal stripping method. First, the scrap panels are fed onto a chain-driven heating platform. Here, controlled heating softens the PE plastic core without burning the aluminum, preparing it for separation.

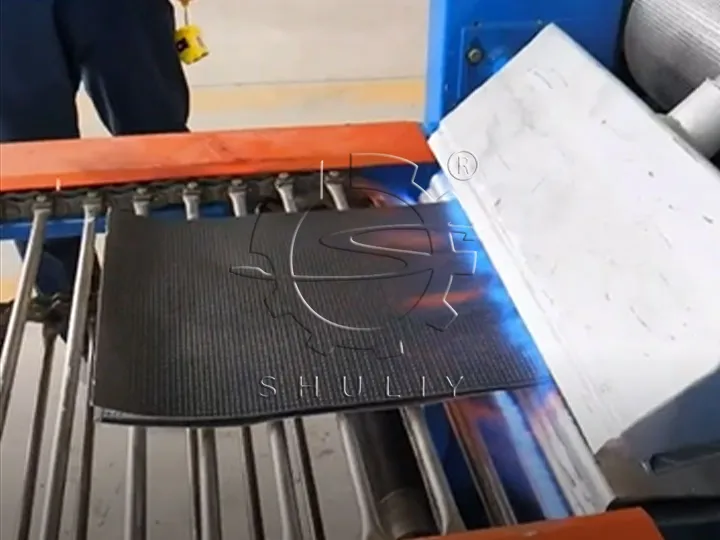

Next, the heated panel enters the main unit. This ACP Separating Machine utilizes a set of robust, engraved rollers that have undergone specialized heat treatment. These high-grip rollers apply immense physical pressure, cleanly stripping the aluminum sheets from the softened plastic core in a single pass. The result is two distinct streams of material—clean aluminum and a PE plastic core—ready for collection.

Key Features of the Shuliy SL-Series ACP Separator

Continuous operation demands robust components. We equip our machines with internationally recognized electricals to ensure maximum uptime and a long service life. The SL-1000 model features a premium ABB inverter, while all models in the SL-series utilize Schneider low-voltage electrical components for proven, day-in, day-out reliability.

The SL-Series is engineered for versatility. The robust design of our SL-800 modelACP Recycling Machine , for example, can process panels with a thickness ranging from 2.5mm to 13mm. It effectively handles an aluminum layer thickness of ≥0.12mm and is even capable of processing composite panels with steel layers up to 0.5mm, expanding your potential sources of raw material.

Profitability depends on controlling operational costs. As a dedicated Aluminum Plastic Separator, our machine is designed for efficiency. The SL-600 model operates with a lean 2.2KW motor and consumes approximately 2.5kg of gas per hour. The larger SL-800, powered by a 4KW motor, processes material with a gas consumption of around 3.75kg/h. These clear metrics allow you to accurately forecast your operational expenses and ROI.

SL-Series ACP Recycling Machine Specifications

Successful Aluminum Composite Panel Recycling requires choosing the right equipment for your specific needs. This table outlines the key specifications for each model in the Shuliy SL-Series.

| Sifa | SL-600 | SL-800 | SL-1000 |

|---|---|---|---|

| Working Width | 600 mm | 800 mm | 1000 mm |

| Nguvu ya Injini | 2.2 KW | 4.0 KW | 4.0 KW |

| Dimensions (L*W*H) | 1400x1500x1100 mm | 2300x2000x1100 mm | 3900x2500x1100 mm |

| Weight (Approx.) | 800 kg | 1200 kg | 1300 kg |

| Rated Capacity* | Approx. 4 tons / 8 hours | Approx. 4 tons / 8 hours | Approx. 4 tons / 8 hours |

Heta produkter

Maskin för klippning av plastpellets | Plastgranulatklippare

Denna plastpellets klippmaskin är den sista…

Banda la kupaka poda kwa mikono

Banda la kupaka poda kwa mikono ni ndogo…

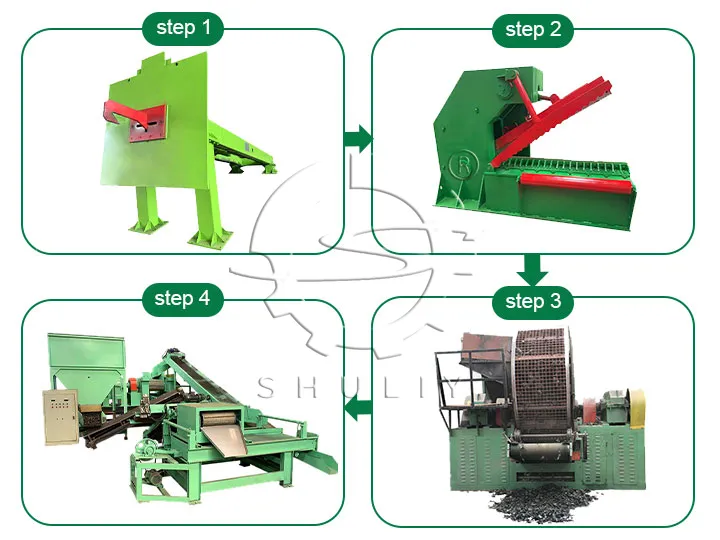

Turnkey OTR Tire Recycling Plant for Mining & Heavy Duty Tires

Utoaji wa matairi ya Off-the-Road (OTR) unaleta…

Mašina za pravljenje plastičnih peleta

En plastpelletstillverkningsmaskin är en återvinning…

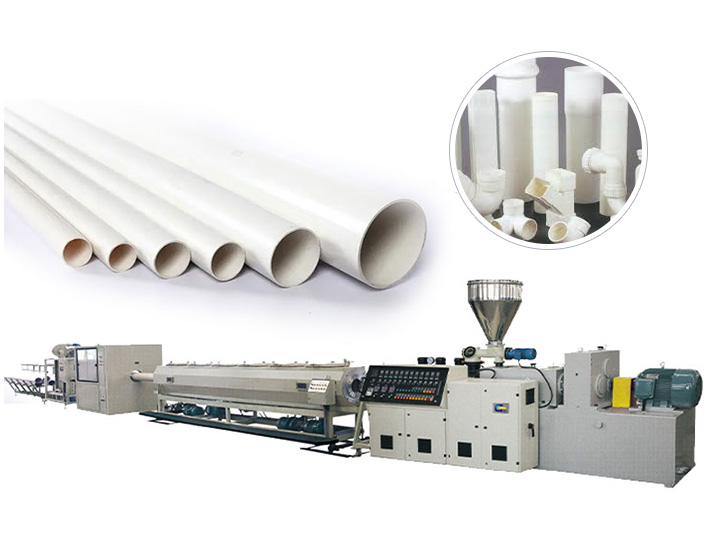

Mashine ya Kutengeneza Mifereji ya Plastiki | Mchakato wa Uzalishaji wa Mifereji ya PPR HDPE PVC

Vårt företag har ett komplett utbud av plast…

Mashine ya granuli ya nta ya parafini|Kipakizi cha pellet cha parafini cha viwanda

Paraffinvax granulatmaskin utnyttjar den låga…

Tank ya kuosha filamu za plastiki baridi

Tank ya kuosha inatumika kwa kuosha…

OTR-däck-stålbeheadare för 1800-4000 mm gruvdäck

Gharama kubwa zaidi iliyofichwa katika tairi la OTR…

Mashine ya Kukata Mipira kwa Ufanisi wa Urejelezaji wa Mipira

Usindikaji wa goma zilizopasuliwa unahitaji wa kuaminika na…