Scrap Aluminum Composite Panels (ACP) from construction and signage industries represent a significant waste challenge. However, locked within these panels are valuable aluminum and plastic resources.

At Shuliy, we provide the ACP Recycling Machine to turn this waste into a high-return revenue stream. This guide provides an in-depth look at the Shuliy SL-Series, a machine designed to efficiently separate these materials and maximize your profitability.

How Our ACP Delaminating Technology Works

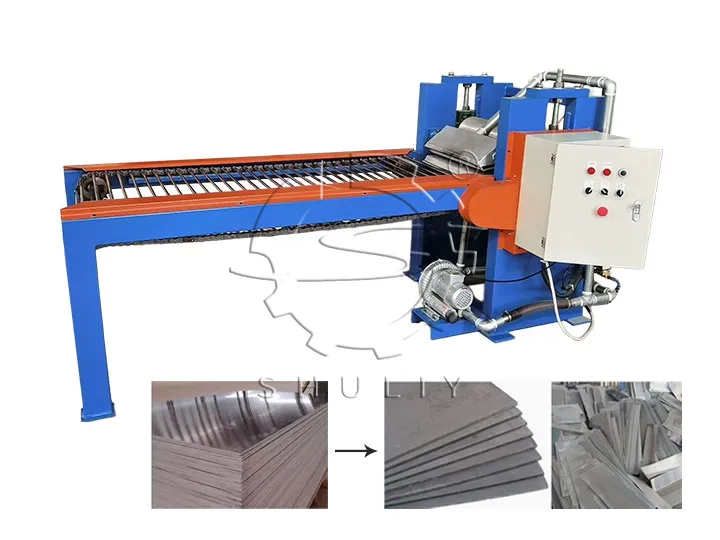

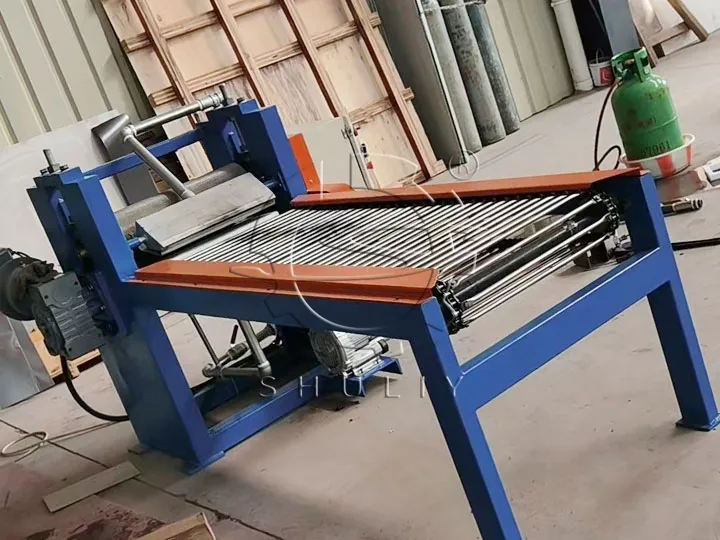

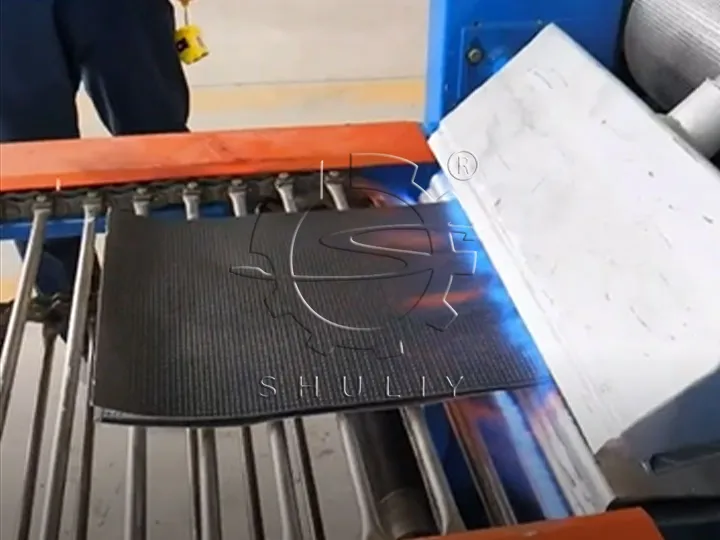

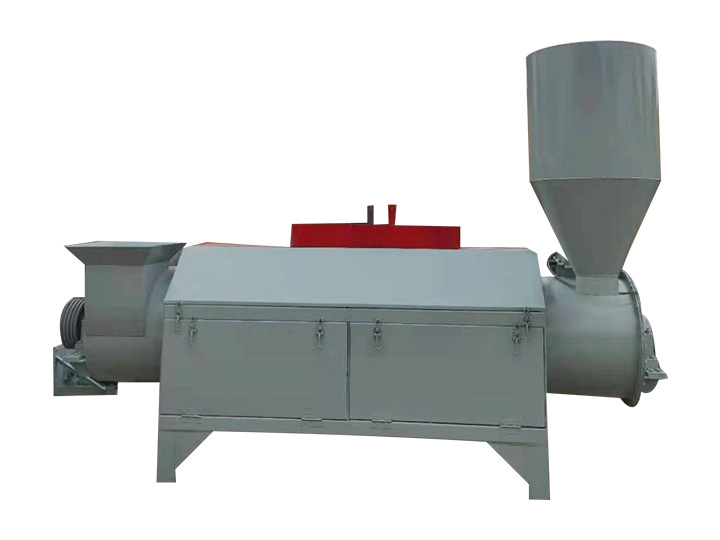

The core of our process is a highly efficient, two-stage thermal stripping method. First, the scrap panels are fed onto a chain-driven heating platform. Here, controlled heating softens the PE plastic core without burning the aluminum, preparing it for separation.

Next, the heated panel enters the main unit. This ACP Separating Machine utilizes a set of robust, engraved rollers that have undergone specialized heat treatment. These high-grip rollers apply immense physical pressure, cleanly stripping the aluminum sheets from the softened plastic core in a single pass. The result is two distinct streams of material—clean aluminum and a PE plastic core—ready for collection.

Key Features of the Shuliy SL-Series ACP Separator

Continuous operation demands robust components. We equip our machines with internationally recognized electricals to ensure maximum uptime and a long service life. The SL-1000 model features a premium ABB inverter, while all models in the SL-series utilize Schneider low-voltage electrical components for proven, day-in, day-out reliability.

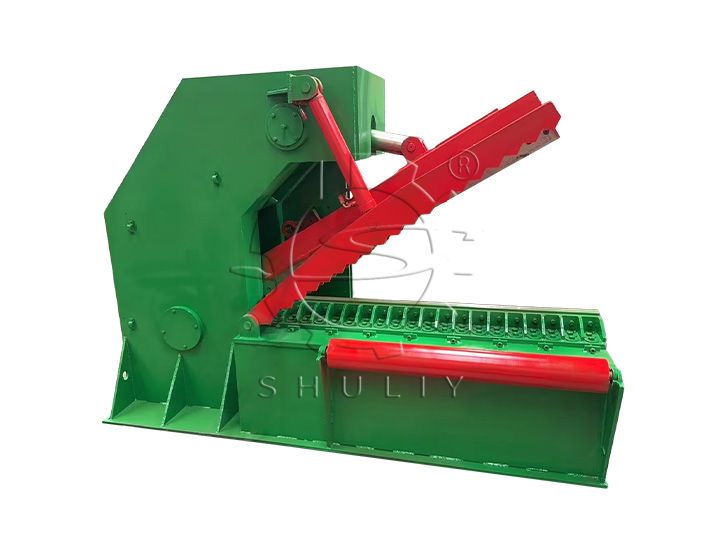

The SL-Series is engineered for versatility. The robust design of our SL-800 modelACP Recycling Machine , for example, can process panels with a thickness ranging from 2.5mm to 13mm. It effectively handles an aluminum layer thickness of ≥0.12mm and is even capable of processing composite panels with steel layers up to 0.5mm, expanding your potential sources of raw material.

Profitability depends on controlling operational costs. As a dedicated Aluminum Plastic Separator, our machine is designed for efficiency. The SL-600 model operates with a lean 2.2KW motor and consumes approximately 2.5kg of gas per hour. The larger SL-800, powered by a 4KW motor, processes material with a gas consumption of around 3.75kg/h. These clear metrics allow you to accurately forecast your operational expenses and ROI.

SL-Series ACP Recycling Machine Specifications

Successful Aluminum Composite Panel Recycling requires choosing the right equipment for your specific needs. This table outlines the key specifications for each model in the Shuliy SL-Series.

| 特点 | SL-600 | SL-800 | SL-1000 |

|---|---|---|---|

| Working Width | 600 mm | 800 mm | 1000毫米 |

| 电机功率 | 2.2 KW | 4.0 KW | 4.0 KW |

| Dimensions (L*W*H) | 1400x1500x1100 mm | 2300x2000x1100 mm | 3900x2500x1100 mm |

| Weight (Approx.) | 800公斤 | 1200公斤 | 1300 kg |

| Rated Capacity* | Approx. 4 tons / 8 hours | Approx. 4 tons / 8 hours | Approx. 4 tons / 8 hours |

热销产品

橡胶粉生产线 | 废旧轮胎回收厂

橡胶粉加工生产线专门用于…

带式爬升输送机 | 倾斜运输机

带式爬升输送机是一种必不可少的机器…

静电喷涂机 | 手动粉末喷涂枪

静电喷涂机是用于…的工业设备

PET瓶标签去除回收机

PET瓶标签去除器是塑料…不可或缺的工具

PET瓶回收用摩擦洗涤机

摩擦洗涤机的工作过程如…

塑料颗粒脱水机

塑料颗粒脱水机用于去除…

适用于1400-4000mm轮胎的越野轮胎切割机

OTC-4000是一款专用的越野轮胎切割机…

EPE EPS泡沫颗粒生产线

EPS泡沫造粒生产线适用于…

轮胎侧壁切割机

TCC-1250 轮胎侧壁切割机是一款…