Can plastic foam be recycled?

Recently, due to the implementation of the waste separation policy, more and more residents have begun to pay attention to whether plastic foam can be recycled. In this article, we will tell you the answer to this question.

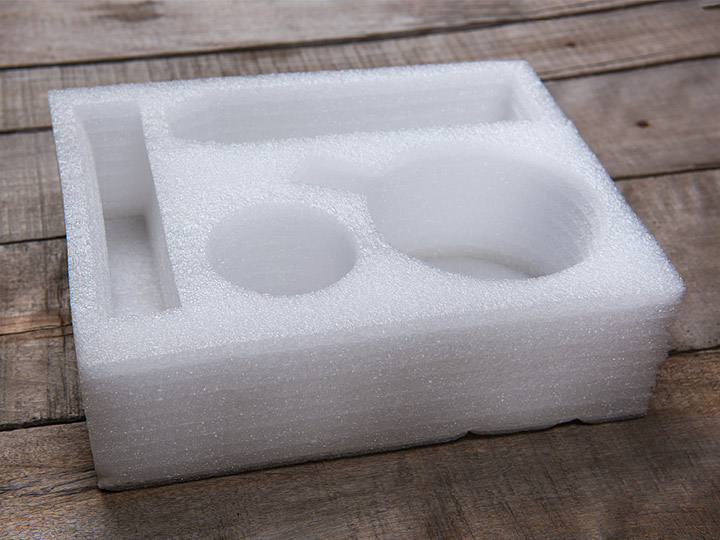

In daily life, we can see many different kinds of plastic foam products. As a common packaging material, plastic foam plays a big role in our daily life. For example, it can pack TVs, refrigerators, air conditioners, and other home appliances, and it can also pack fragile products such as ceramics and glass. What we want to tell you here is that these plastic foams can be recycled. They can be divided into physical recycling and chemical recycling according to different recycling methods.

Physical recycling

In fact, plastic foam not only has a good shockproof function but also has good heat insulation function. Many manufacturers recycle plastic foam, crush it, and then re-bond it to make insulation layers of various insulation materials.

Another method of physical recycling is to put the plastic foam into a high-temperature environment to melt it, then extrude it, cool it, and make it into new plastic pellets, and then recycle or reuse it to make other plastic products. Our company provides a set of plastic recycling line, and it can help you to change the plastic foam into a plastic pellet.

At present, the method of recycling through plastic foam recycling equipment is the most commonly used and the most effective resource for recycling.

chemical method

The method of using chemical reagent to process EPS materials is not new, but there are still many problems to be overcome before it can be put into production. At present, there are two main ideas for the chemical processing of materials. On the one hand, the material is processed into smaller molecular compounds, which are then conducive to environmental degradation. On the other hand, these polymer compounds are processed into new materials through cracking, hydrogenation, gasification, etc., and their quality is comparable to new materials.

In addition, there are other methods, such as manufacturing rust-proof rust-proof paint, manufacturing multi-functional resin glue, manufacturing anti-seepage, and leak-proofing agents, and using it as an asphalt enhancer, which provides new research directions for the recovery of plastic foam.