The Unsung Hero: Why the Hard-Gear Reducer for Extruder is Critical to Longevity

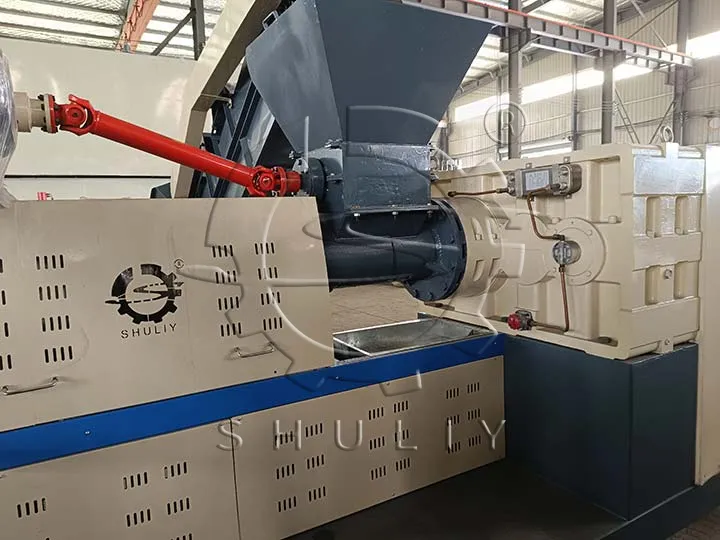

When evaluating a plastic granulator, buyers often focus on the screw design and motor power. While these are important, the component that truly determines the machine’s durability and long-term performance is often overlooked: the gearbox. The granulator gearbox, or reducer, is the unsung hero that translates the motor’s speed into raw power.

Choosing a machine with the right type of gearbox is the difference between a reliable recycling machine and one plagued by problems. This article explains why a hard-gear reducer for extruder technology is not just an option, but an essential component for any serious recycling operation.

The Immense Demands on a Granulator Gearbox

The gearbox in a plastic granulator operates under constant, extreme stress. Its primary job is to manage the immense torque in plastic extrusion. This is especially demanding because different materials require different kinds of force:

- Rigid Plastics: Processing HDPE flakes in a rigid plastic recycling line requires massive initial torque to crush and plasticize the tough material.

- Soft Plastics: Running a plastic film recycling line demands constant, unwavering torque to ensure a smooth and consistent melt flow.

A standard, or “soft-gear,” reducer will quickly wear under these conditions, leading to vibration, increased noise, and eventual extruder gearbox failure. The cost of extruder downtime from a failed gearbox can be catastrophic to a business.

The Engineering Advantage: What is a Hard-Gear Reducer for Extruder?

The term “hard-gear” refers to the metallurgical properties of the gears themselves. Unlike standard gears, a heavy-duty gear reducer uses hardened steel gears. These gears undergo specialized heat treatments (like carburizing and quenching) followed by precision grinding.

This process creates gears that are:

- Extremely Wear-Resistant: The hardened surface can withstand constant friction and pressure without degrading.

- Capable of Handling Higher Loads: They can transmit significantly more torque than soft gears of the same size.

- More Efficient and Quieter: Precision grinding ensures perfect gear meshing, which reduces energy loss and makes for a low noise recycling machine.

This superior engineering is the foundation of industrial granulator reliability.

From Engineering to Uptime: The Business Benefits

Choosing a machine with a high torque gearbox for granulator applications translates directly to your bottom line.

- Increased Granulator Machine Longevity: The wear resistance of hard gears means the gearbox lasts much longer, protecting your investment.

- Reduced Maintenance: A low maintenance plastic granulator allows you to focus on production, not repairs. This robust design requires only standard gear reducer lubrication checks.

- Maximized Recycling Machine Uptime: The most significant benefit is reliability. A hard-gear reducer is far less likely to fail, preventing costly production halts and ensuring your operation runs smoothly.

A Standard of Quality Across Our Entire Range

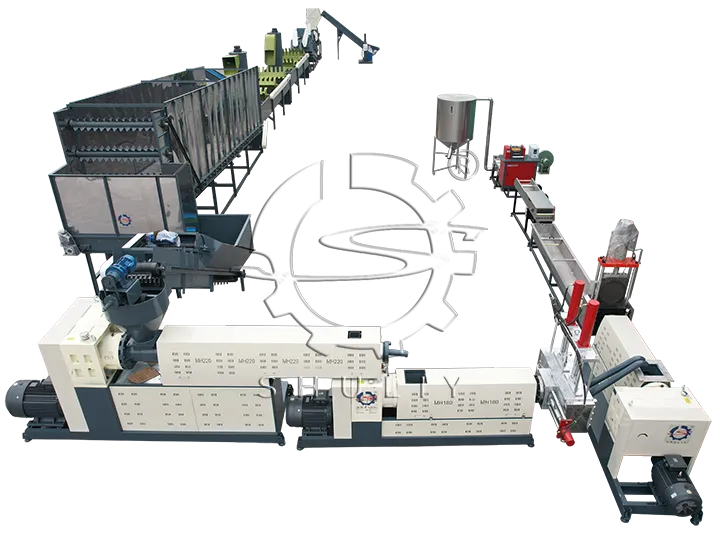

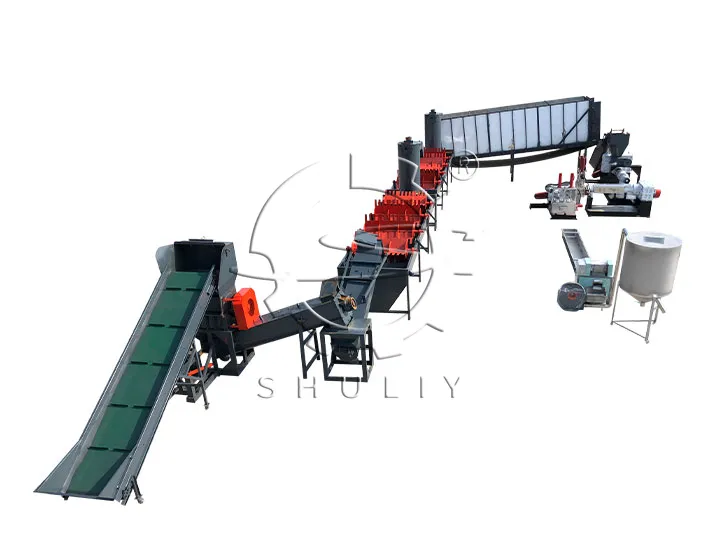

We believe that core component quality should be non-negotiable. That is why every machine we build, from our entry-level model to our largest industrial line, comes standard with a hard-gear reducer for extruder applications.

From the Model 200 in our Type 105 to the powerful Model 330 in our Type 220, every machine is built around a durable, heavy-duty gearbox. This ensures that no matter the scale of your operation, you are investing in a durable plastic granulator.