Plant Layout: How Much Space Do You Need for a PET Washing Line?

Before you purchase a single machine, a critical question for your plastic recycling plant design is: “How much space do I need?” The required factory space for a washing line depends heavily on capacity, but a smart PET recycling plant layout is about more than just the machine footprint.

Here are some general guidelines for the total area, including storage and access:

- 500 kg/h Line: Approximately 600-800 m² (6,500-8,600 ft²)

- 1500 kg/h Line: Approximately 1,200-1,600 m² (13,000-17,000 ft²)

- 3000 kg/h Line: Approximately 2,000-2,500 m² (21,500-27,000 ft²)

What consumes this space?

- Raw Material Storage: You need ample space to store compressed bales before they are processed.

- The Production Line: Our PET bottle washing lines are typically designed in a linear or U-shape. The PET line dimensions for a 1000kg/h line are roughly 50-60 meters in length.

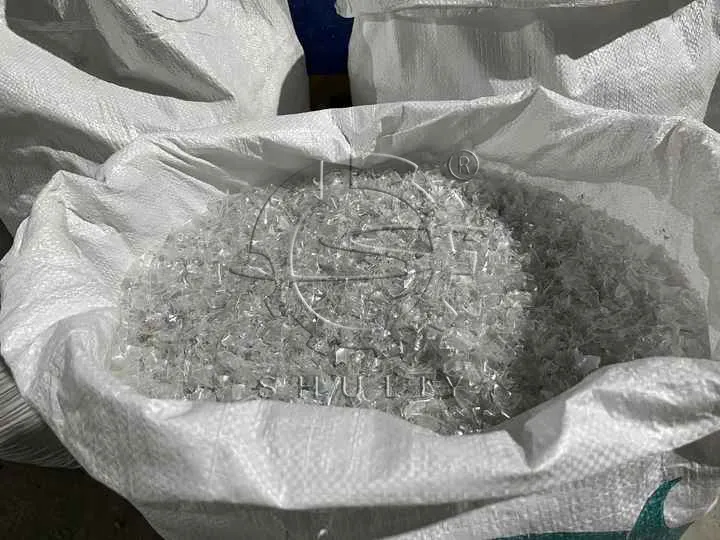

- Finished Product Storage: You need a dry, clean area for storing big bags of rPET flakes.

- Water Circulation & Treatment System: A closed-loop water system requires space for sedimentation tanks and filters.

- Maintenance & Access: Leave at least 1.5-2 meters of clear space around the entire line for safe operation and maintenance.

Our Service: We provide complimentary, customized 2D or 3D recycling plant layout drawings to help you visualize the line in your specific facility, ensuring a perfect fit from day one.