Turnkey OTR Tire Recycling Plant for Mining & Heavy Duty Tires

Turnkey OTR Tire Recycling Plant for Mining & Heavy Duty Tires

The disposal of Off-the-Road (OTR) tires presents a significant financial and environmental liability for mining, construction, and port operations. Their immense size and robust construction make them impossible to process with standard equipment. Our fully-automatic OTR tire recycling line is an engineered system designed specifically to conquer this challenge, converting these liabilities into distinct, high-value revenue streams: clean steel and high-purity rubber powder.

The Unique Engineering Challenge of OTR Tires

Standard tire recycling systems fail when faced with OTR tires due to their unique material properties. Effective OTR tire waste management requires a system built to handle:

- Immense Size & Weight: Tires can exceed 4000mm in diameter and weigh several tons, requiring machinery with massive structural integrity and torque.

- Extremely Tough Bead Wire: The steel bead wire bundle in an OTR tire can be over 5cm thick, capable of destroying conventional debeaders and shredders instantly.

- Thick, Dense Rubber: The sheer thickness of the tread and sidewall demands exceptionally high cutting force and shredding power, far beyond that needed for car or truck tires.

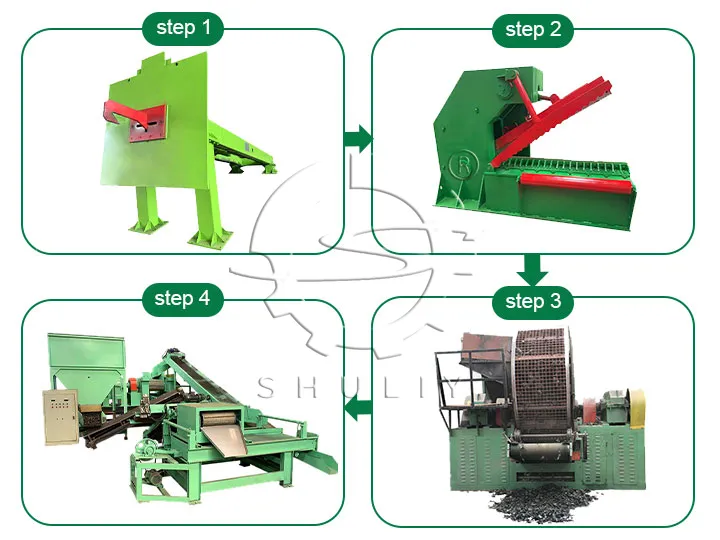

Shuliy Engineered Process: A Step-by-Step Breakdown

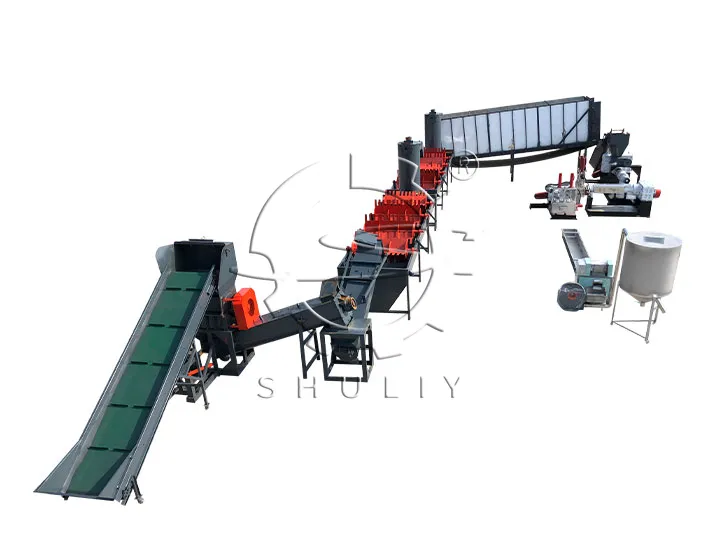

Our system is a multi-stage, PLC-controlled process designed for maximum efficiency and component longevity. Each stage prepares the material for the next, ensuring a smooth and profitable operation.

Step 1: Pre-Processing – The Critical First Cut

The initial breakdown is crucial for protecting downstream equipment. We offer two specialized solutions based on tire size:

- For Giant Tires (>2100mm / R35-R63): The OTR Dismantling Machine is deployed. Its powerful arm and Tungsten Carbide Alloy blade systematically cut the tire into 4-6 smaller, manageable pieces (tread, sidewalls, bead sections) in just 10-30 minutes. This pre-cutting drastically reduces stress on the primary shredder.

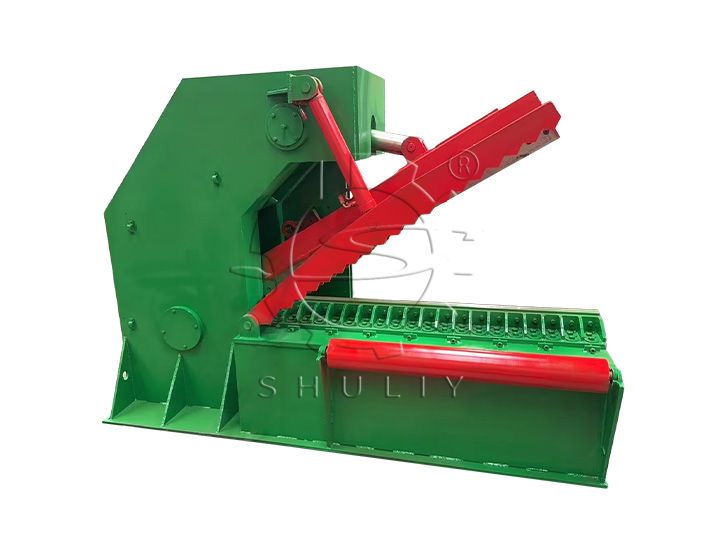

- For Large Tires (1400mm – 4000mm): The OTR Debeader (Steel Ring Separator) directly targets the bead. It powerfully extracts the entire steel wire bundle from the tire rim in a single, clean piece within 2-5 minutes, preparing the tire for direct shredding.

Step 2: Primary Shredding – The Heavy-Duty Workhorse

The pre-cut tire sections or debeaded tire carcass are fed into our Heavy-Duty Twin-Shaft Shredder (1200 model or larger). This low-speed, high-torque machine uses robust, interlocking blades made of composite alloy steel to shear the thick rubber into uniform 60-150mm blocks, also known as Tire-Derived Fuel (TDF).

Step 3: Granulation & Steel Liberation

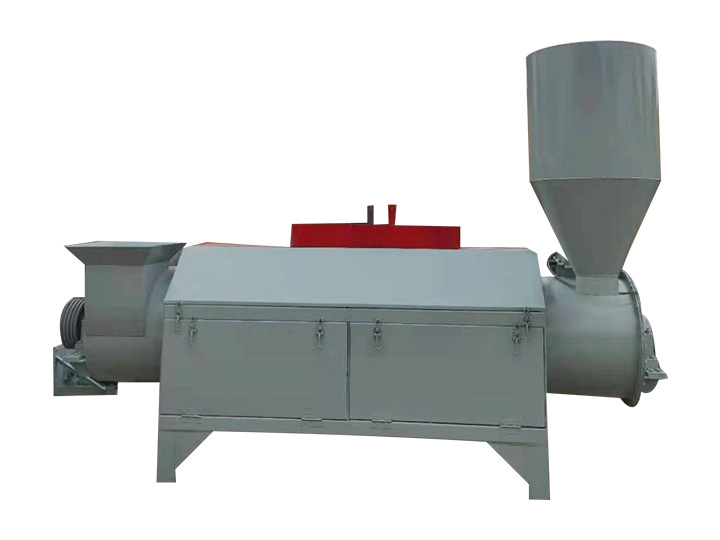

The TDF blocks are conveyed to the Rubber Granulator (Crusher). This machine grinds the blocks down while a powerful integrated magnetic separation system pulls out the liberated steel wire, achieving over 99% purity. Our granulators can produce a range of rubber powder sizes, typically from 5 to 40 mesh, depending on the client’s target market. For example, our SL-560 model can produce 600-700 kg/h of 20 mesh rubber powder.

Step 4: Final Purification & Collection

A high-volume Fiber Separation System uses airflow to remove nylon and textile fibers from the rubber granules. The final, clean rubber powder is then pneumatically conveyed to an automated bagging system, ready for sale.

Custom Configurations for Your Specific Needs

While we are experts in OTR processing, we understand that recycling needs vary. For clients handling smaller tires, our semi-automatic recycling line offers a lower initial investment, while our fully automatic tire recycling line is optimized for high-volume car and truck tire processing.

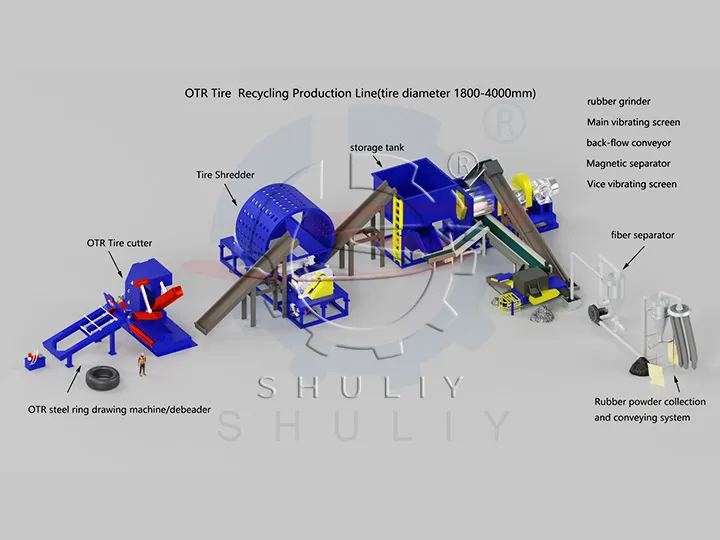

For OTR applications, we recommend two primary configurations:

Configuration 1: The Standard OTR Plant

- Application: Ideal for tires from 1400mm to 4000mm.

- Core Process: OTR Debeader → Heavy-Duty Shredder → Granulator & Separation System.

- Best for: Professional recycling centers and operations dealing with a wide range of large, but not giant, OTR tires.

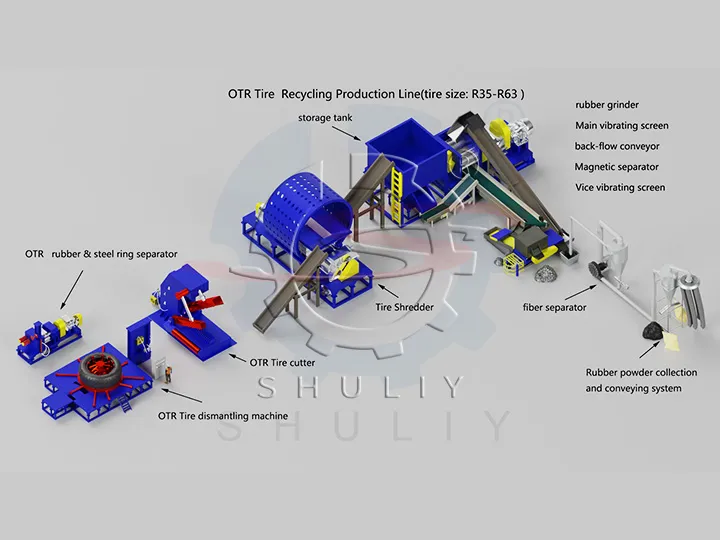

Configuration 2: The Flagship OTR Plant

- Application: Engineered specifically for the largest mining tires (≥2100mm / R35+).

- Core Process: OTR Dismantling Machine → Heavy-Duty Shredder → Granulator & Separation System.

- Best for: Mining companies, large port authorities, and national-level waste management projects. This is our flagship OTR tire recycling plant configuration, designed for maximum long-term profitability by prioritizing the longevity of the most critical components.

The Data Behind the Profitability (ROI)

The investment in a professional OTR tire recycling plant is justified by the creation of multiple, consistent revenue streams from a waste product. Your primary outputs are:

- High-Purity Rubber Powder (5-40 Mesh): A valuable commodity sold for use in rubberized asphalt, sports turf infill, rubber flooring, and as a raw material for molded rubber products.

- High-Tensile Steel Wire: The steel from OTR tire beads is exceptionally high quality. Once cleaned, it is sold as premium scrap steel to foundries at a price point significantly higher than mixed scrap.

- Nylon Fiber: Can be baled and sold as a high-calorific value Tire-Derived Fuel (TDF) for use in industrial furnaces or cement kilns.

Contact our team with your local market prices for these commodities, and we can provide a detailed ROI projection tailored to your operational costs.

Why Partner With Us?

OTR-Focused Engineering: Our systems are not just scaled-up versions of smaller lines. They are designed from the ground up to handle the unique stresses of OTR tire processing, from the blade materials (Cr12MoV and Tungsten Carbide Alloy) to the gearbox specifications.

Data-Driven Transparency: We provide clear performance data, from the throughput of each machine (e.g., OTR Cutter at 2 cuts/minute) to the power consumption (kW) of each component, allowing you to accurately forecast your operational costs.

End-to-End Turnkey Solution: We offer a complete service package, including site layout design, manufacturing, installation, operator training, and ongoing after-sales support for your turnkey solution.

Ready to convert your tire liability into a revenue stream? Contact our engineering team today for a free project assessment and a detailed, custom quote.

Hot Product

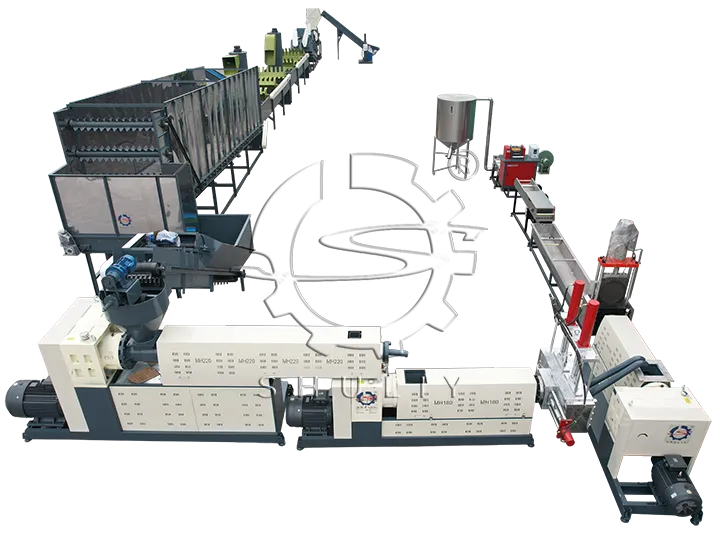

Plastic Film Recycling Machine

The plastic film recycling machine is highly efficient…

Plastic pellet dehydrator

The plastic pellet dehydrator is used to remove…

EPE Recycling Machine for Foam Pelletizing

Waste EPE foam pelletizing machine is suitable for…

Rigid plastic recycling lines for HDPE PP

The plastic recycling lines for HDPE PP and…

Strand Pelletizer Machine for Rigid Plastic Recycling

Strand pelletizer machine offer recycled pelletizing technology for…

OTR Tire Cutting Machine for 1400-4000mm Tires

The OTC-4000 is a specialized OTR tire cutting…

Industrial Rubber Floor Tiles Making Machine for High-Density Production

The SL-120T Pro is a professional-grade rubber floor…

Tire Sidewall Cutter Machine

The TCC-1250 tire sidewall cutter machine is a…

Paraffin wax granule machine|Industrial paraffin pelletizer

The paraffin wax granule machine utilizes the low…