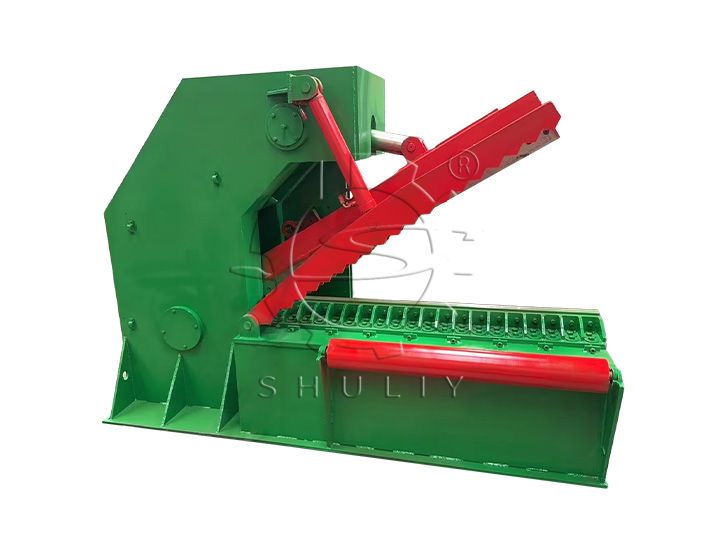

OTR Tire Cutting Machine for 1400-4000mm Tires

The OTC-4000 is a dedicated tire recycling pre-treatment machine specifically engineered to handle the massive dimensions and structural density of Off-The-Road (OTR) tires. Unlike standard cutters, this unit accommodates tire diameters from 1400mm up to 4000mm, addressing the critical processing gap in the mining and heavy construction sectors.

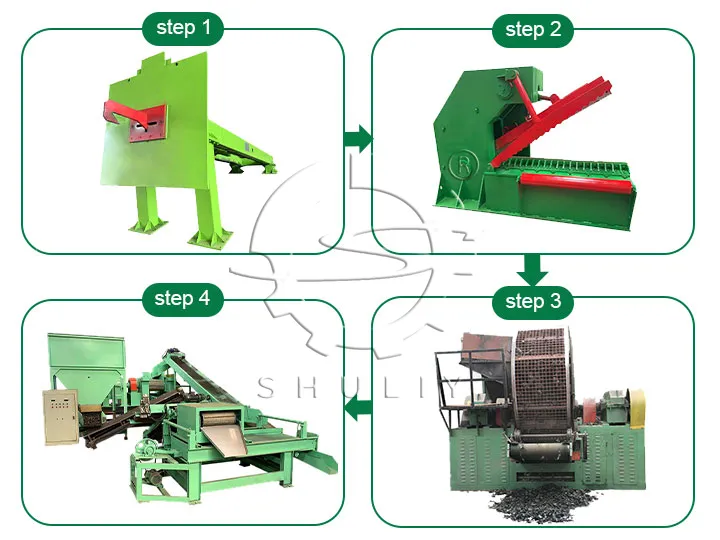

As a primary-stage commercial tire cutting equipment, the OTC-4000 reduces giant waste tires into manageable segments. This reduction is essential for logistical feasibility and prepares the material for further size reduction in a complete OTR tire recycling line.

Tire Cutting Machine Technical Specifications

The OTC-4000 de-beaded tire cutter distinguishes itself through robust construction and specific performance metrics designed for high-load environments.

| Parameter | Specification | Data Analysis |

|---|---|---|

| Model | OTC-4000 | Heavy-Duty Hydraulic Series |

| Power | 7.5 kW | High-torque hydraulic drive system |

| Dimensions (LWH) | 3.13m * 1.65m * 2.7m | Large envelope for 4-meter tires |

| Machine Weight | 7200 kg | Provides stability against high shear forces |

| Tire Size Capacity | 1400mm – 4000mm | Covers majority of mining/OTR tires |

| Output Rate | 2 cuts / minute | Optimized for shear force over speed |

| Blade Material | Cr12MoV Steel | High wear resistance & impact toughness |

An OTR tire cutting machine requires immense structural integrity effectively slice through thick rubber and reinforced steel cords found in earthmover tires. The OTC-4000 weighs 7200kg. This substantial mass is not merely dead weight; it is a functional necessity that absorbs the reaction forces generated during the shearing process, eliminating vibration and preventing frame deformation.

Functioning as an industrial large tire slicer, the machine utilizes a 7.5kw motor to drive a high-pressure hydraulic system. While the kilowatt rating may appear standard, the hydraulic gearing multiplies the force, allowing the blade to penetrate solid rubber blocks that would stall rotary shredders. The output rate of 2 cuts per minute reflects this focus on torque—delivering slow, deliberate, and unstoppable cutting power.

Blade Technology and Operational Requirements

The cutting efficiency of the OTC-4000 serves its role as a specialized de-beaded tire cutter.

- Cr12MoV Blades: The cutter employs Chromium-Molybdenum-Vanadium cold work die steel. This metallurgy offers a hardness balance that resists chipping when encountering thick steel wires inside mining tires.

- Pre-Condition: Operators must ensure tires are de-beaded (steel bead rings removed) prior to feeding. The machine is optimized for shearing the tire body (sidewalls and tread), distinct from bead wire extraction units.

Applications in Heavy Industry

This machine is the definitive solution for heavy equipment tire disposal. It enables:

- Mining Sites: Processing spent haul truck tires on-site to reduce storage volume.

- Recycling Plants: Pre-cutting inputs for secondary shredders, preventing overload.

- Logistics: Transforming “untransportable” 4-meter tires into stackable rubber blocks.

As a construction tire recycling machine, it handles waste from loaders, scrapers, and articulated trucks, turning hazardous waste piles into valuable raw material resources.

Hot Product

EPE Recycling Machine for Foam Pelletizing

Waste EPE foam pelletizing machine is suitable for…

Vertical & Horizontal Plastic Baler Machine for Bottles Bags Cardboard & More

The commercial plastic baler is mainly used for…

Belt conveyor | Plastic bottle sorting table

Structure of belt conveyor The belt sorting table…

Automatic feeding machine | Forced feeder for plastic recycling

This automatic feeding machine is designed to simulate…

Frictional washing machine for PET bottle recycling

Working process of the frictional washing machine As…

Turnkey OTR Tire Recycling Plant for Mining & Heavy Duty Tires

The disposal of Off-the-Road (OTR) tires presents a…

Horizontal Styrofoam Shredder

A horizontal styrofoam shredder is mainly used to…

Cooling tank | Pellet cooling machine

The plastic cooling tank is a very important…

Plastic film cold washing rinsing tank

The rinsing tank is used for rinsing the…