Su guía completa sobre el soporte posventa de granuladores de plástico

Elegir la granuladora de plástico adecuada es un paso crítico. Pero para cualquier negocio serio de reciclaje, la pregunta que sigue es igual de importante: “¿Qué sucede después de que se entrega la máquina?” La calidad de la experiencia posterior a la compra—desde la instalación hasta el servicio a largo plazo—es lo que convierte una buena máquina en un activo rentable y duradero.

No consideramos la entrega de su máquina como el fin de una transacción, sino como el comienzo de una asociación a largo plazo. Esta guía proporciona una hoja de ruta clara de nuestro sistema integral de soporte postventa para granuladoras de plástico, diseñado para ofrecerle total tranquilidad y garantizar que alcance la máxima productividad desde el primer día.

Etapa 1: Preinstalación y Preparación

Un inicio sin problemas comienza antes de que llegue su equipo. Como parte de nuestro proceso de puesta en marcha de máquinas de reciclaje, le proporcionamos toda la documentación técnica necesaria para preparar sus instalaciones. Esto incluye:

- Dibujos detallados del diseño: Proporcionamos dimensiones precisas para su modelo específico, por ejemplo, una máquina Tipo 150 (3,00.70,8 m), lo que le permite planificar eficazmente el espacio en su planta.

- Especificaciones de requisitos de alimentación: Recibirá información clara sobre las necesidades eléctricas de su máquina. Para un modelo Tipo 180 con un motor principal de 55kw, sabrá exactamente qué infraestructura eléctrica preparar.

- Requisitos de cimentación y servicios: Detallamos la cimentación necesaria y las conexiones de suministro de agua, asegurando que su sitio esté listo para una instalación sin contratiempos.

Etapa 2: Instalación y Puesta en Marcha de la Máquina Peletizadora

Cuando su máquina llegue, no estará solo. Proporcionamos un marco de soporte sólido para guiarle durante la fase de instalación y puesta en marcha de la peletizadora.

Nuestra guía de instalación de la plastic granulator es un recurso integral paso a paso que cubre todo, desde el montaje mecánico hasta el cableado eléctrico. Este paquete de soporte incluye:

- Manuales y diagramas detallados: Guías claras e ilustradas que llevan a su equipo a través de todo el proceso.

- Tutoriales en vídeo: Demostraciones visuales de los pasos clave de la instalación para mayor claridad y seguridad.

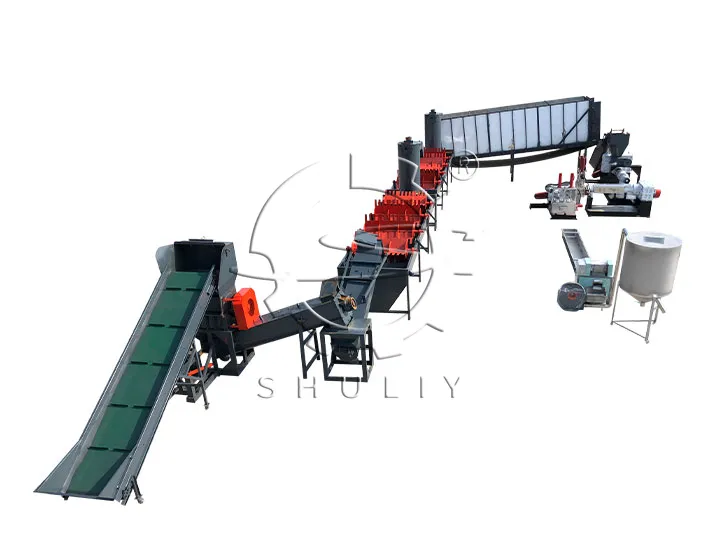

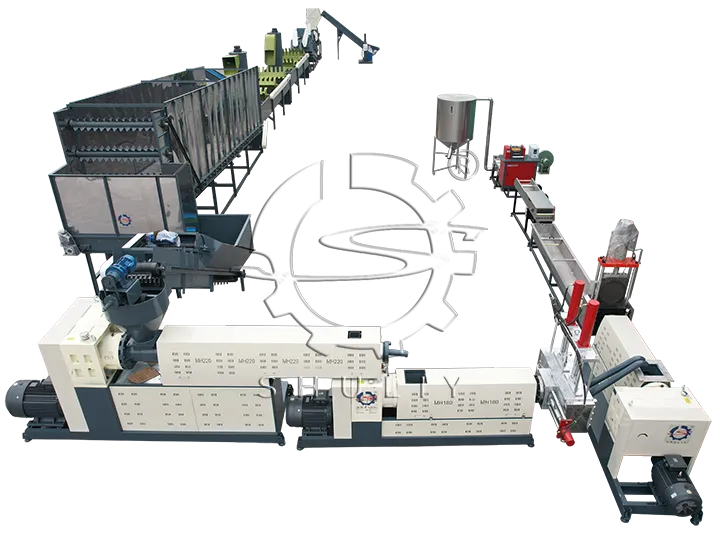

- Soporte de ingeniería opcional en el sitio: Para instalaciones complejas, como una completa Línea de reciclaje de film plástico, podemos enviar un ingeniero experimentado a su instalación. Nuestro ingeniero supervisará la puesta en marcha de la línea de peletización, asegurará que todo funcione según las especificaciones y proporcionará capacitación práctica inicial.

Etapa 3: Capacitación del equipo en operación de la granuladora de plástico

La eficiencia de una máquina está directamente ligada a la habilidad de sus operadores. Nos comprometemos a capacitar a su equipo con el conocimiento necesario para operar de forma segura y productiva.

La formación para operadores de granuladoras de plástico se basa en nuestro detallado manual de operación de peletizadoras de plástico, que recibirá con su máquina. La formación incluye:

- Procedimientos seguros de arranque y parada: Seguir la secuencia correcta para proteger tanto al operador como a la máquina.

- Ajuste de parámetros del proceso: Cómo ajustar la temperatura y la velocidad para diferentes materiales.

- Controles de mantenimiento rutinario: Capacitar a su equipo para realizar las comprobaciones diarias y semanales descritas en nuestras guías de mantenimiento.

- Resolución básica de problemas: Cómo identificar y resolver rápidamente los problemas operativos comunes.

Etapa 4: Asociación a largo plazo y Servicio integral de máquinas de reciclaje

Nuestro compromiso con usted se extiende mucho más allá de la configuración inicial. Hemos construido nuestra reputación ofreciendo un soporte postventa fiable y a largo plazo para granuladoras de plástico.

Soporte técnico de por vida para peletizadoras de plástico

Cuando tenga una pregunta o encuentre un problema, nuestro equipo de técnicos experimentados está aquí para ayudarle. Proporcionamos soporte técnico de por vida por correo electrónico, teléfono o videollamada para asistir en la resolución de problemas de máquinas de reciclaje, ayudándole a resolver incidencias rápidamente y minimizar el tiempo de inactividad.

Proveedor fiable de repuestos para granuladoras de plástico

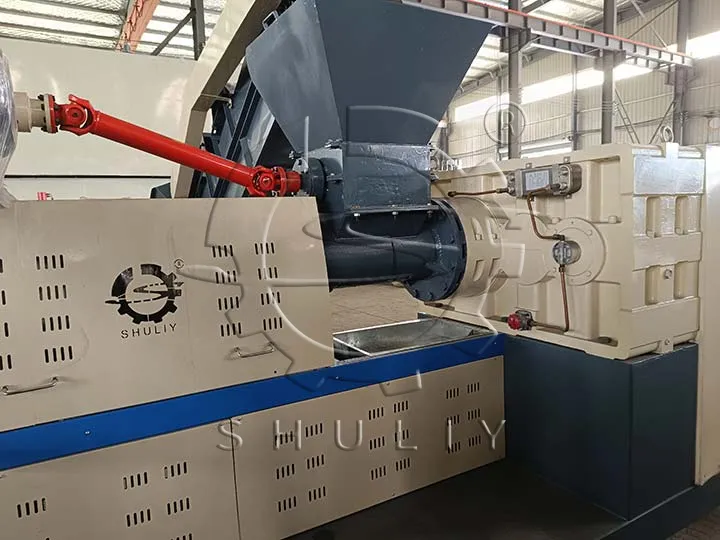

Entendemos que para clientes internacionales, el acceso a repuestos es una preocupación importante. Como fabricante directo de peletizadoras de plástico, mantenemos un inventario completo de repuestos críticos, que incluye:

- Componentes de alto desgaste: Tornillos, barriles y cuchillas de corte específicos para el modelo de su máquina.

- Componentes eléctricos: Calentadores, termopares e inversores de marca.

- Piezas mecánicas: Rodamientos y componentes de cajas de cambios.

Esto garantiza que cuando necesite una pieza, podamos despacharla rápidamente, manteniendo su plastic rigid recycling line en funcionamiento con una interrupción mínima. Nuestro objetivo es ser su socio de confianza durante todo el ciclo de vida de su equipo.