플라스틱 그라뉘레이터 사후 지원에 대한 완전한 가이드

Choosing the right plastic granulator is a critical first step. But for any serious recycling business, the question that follows is just as important: “What happens after the machine is delivered?” The quality of the post-purchase experience—from installation to long-term service—is what transforms a good machine into a profitable, long-term asset.

We view the delivery of your machine not as the end of a transaction, but as the beginning of a long-term partnership. This guide provides a clear roadmap of our comprehensive plastic granulator after sales support system, designed to give you complete peace of mind and ensure you achieve maximum productivity from day one.

Stage 1: Pre-Installation & Preparation

A smooth start begins before your equipment arrives. As part of our recycling machine setup process, we provide you with all the necessary technical documentation to prepare your facility. This includes:

- 상세 레이아웃 도면: 특정 모델에 대한 정확한 치수를 제공합니다. 예를 들어, Type 150 기계(3.00.70.8 m), 귀하의 바닥 공간을 효과적으로 계획할 수 있도록 합니다.

- Power Requirement Specifications: You will receive clear information on the power needs for your machine. For a Type 180 model with a 55kw main motor, you will know exactly what electrical infrastructure to prepare.

- Foundation & Utility Requirements: We outline the necessary foundation and water supply connections, ensuring your site is ready for a seamless installation.

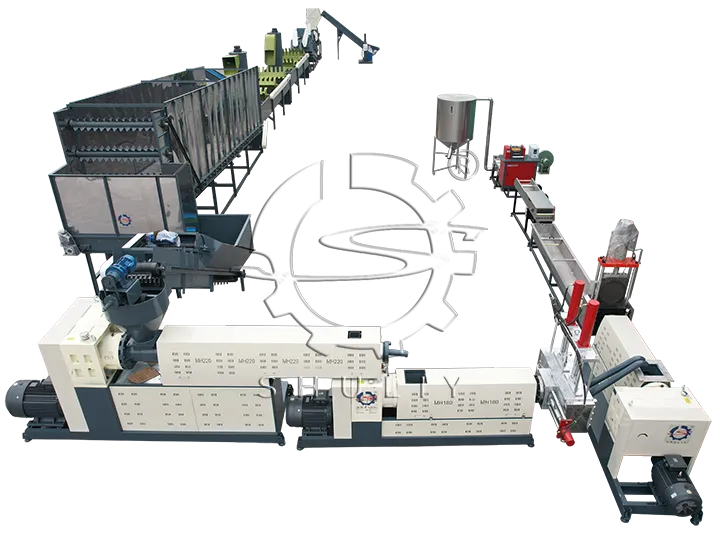

Stage 2: Pelletizer Machine Installation & Commissioning

When your machine arrives, you are not alone. We provide a robust support framework to guide you through the pelletizer machine installation and commissioning phase.

Our plastic granulator installation guide is a comprehensive, step-by-step resource that covers everything from mechanical assembly to electrical wiring. This support package includes:

- Detailed Manuals & Diagrams: Clear, illustrated guides that walk your team through the entire process.

- Video Tutorials: Visual demonstrations of key installation steps for clarity and confidence.

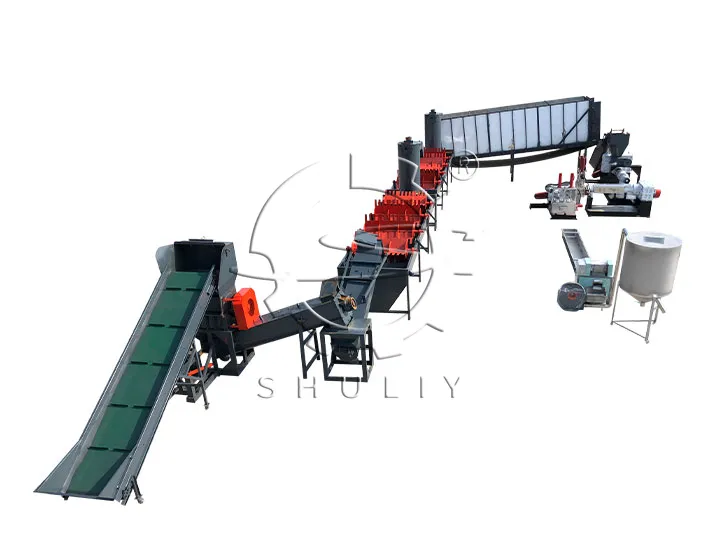

- 선택적 현장 엔지니어링 지원: 전체와 같은 복잡한 설치를 위한 플라스틱 필름 재활용 라인, 숙련된 엔지니어를 귀하의 시설에 파견할 수 있습니다. 우리의 엔지니어는 펠렛화 라인 시운전을 감독하고, 모든 것이 사양에 맞게 작동하는지 확인하며, 초기 실습 교육을 제공합니다.

Stage 3: Empowering Your Team with Plastic Granulator Operator Training

A machine’s efficiency is directly tied to the skill of its operators. We are committed to empowering your team with the knowledge they need for safe and productive operation.

The plastic granulator operator training is based on our detailed plastic pelletizer operation manual, which you will receive with your machine. The training covers:

- Safe Startup and Shutdown Procedures: Following the correct sequence to protect both the operator and the machine.

- Process Parameter Adjustment: How to adjust temperature and speed for different materials.

- Routine Maintenance Checks: Empowering your team to perform the daily and weekly checks outlined in our maintenance guides.

- Basic Troubleshooting: How to identify and resolve common operational issues quickly.

Stage 4: Long-Term Partnership & Comprehensive Recycling Machine Service

Our commitment to you extends far beyond the initial setup. We have built our reputation on providing reliable, long-term plastic granulator after sales support.

Lifetime Plastic Pelletizer Technical Support

When you have a question or encounter a problem, our team of experienced technicians is here to help. We provide lifetime technical support via email, phone, or video call to assist with recycling machine troubleshooting support, helping you resolve issues quickly and minimize downtime.

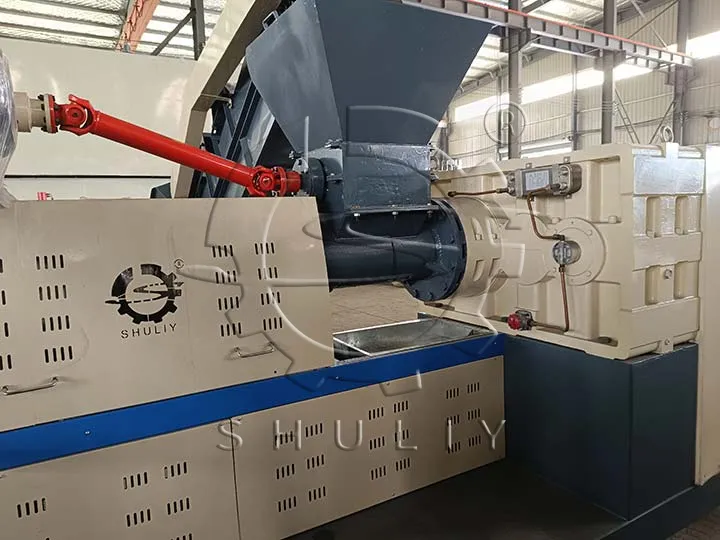

Reliable Plastic Granulator Spare Parts Supplier

We understand that for international clients, access to spare parts is a major concern. As the direct plastic pelletizer manufacturer, we maintain a comprehensive inventory of critical spare parts, including:

- High-Wear Components: Screws, barrels, and cutting blades specifically for your machine model.

- Electrical Components: Heaters, thermocouples, and branded inverters.

- Mechanical Parts: Bearings and gearbox components.

This ensures that when you need a part, we can dispatch it quickly, keeping your plastic rigid recycling line running with minimal interruption. Our goal is to be your trusted partner for the entire lifecycle of your equipment.