Máy sản xuất gạch cao su công nghiệp cho sản xuất mật độ cao

Máy sản xuất gạch cao su công nghiệp cho sản xuất mật độ cao

Nhu cầu toàn cầu về bề mặt bền vững trong phòng tập thể dục, sân chơi, và khu công nghiệp đã biến cao su tái chế thành hàng hóa có lợi nhuận cao. Dòng SL-120T Pro của series lưu hóa chính xác được thiết kế để thu hẹp khoảng cách giữa nguyên liệu cao su tái chế thô và các sản phẩm hoàn chỉnh cao cấp. Bằng cách tích hợp thủy lực áp lực cao với điều khiển nhiệt độ tiên tiến, máy ép lưu hóa gạch cao su này xử lý các hạt cao su và sợi từ dây chuyền tái chế lốp xe thành các giải pháp sàn bền, sẵn sàng thị trường.

Kỹ thuật tiên tiến của máy làm gạch cao su

Khác với thiết bị cấp nhập môn, SL-120T Pro tập trung vào độ cứng cấu trúc và độ chính xác của áp lực. Máy cung cấp lực kẹp danh nghĩa 1.2MN (120 Tấn), được truyền qua bốn xi lanh piston Φ160mm. Môi trường áp lực cao này rất quan trọng để đảm bảo độ đặc của gạch cao su, ngăn ngừa túi khí, và đảm bảo các viên lát hoàn thiện đáp ứng tiêu chuẩn an toàn và chống mài mòn quốc tế.

Các đĩa nóng kích thước 1100 x 1100 x 60 mm được thiết kế để phân phối nhiệt đều. Với nhiệt độ làm nóng tối đa 200°C, hệ thống đảm bảo keo dán (keo) và các hạt cao su liên kết hoàn hảo trên toàn bộ diện tích của viên gạch, dù bạn sản xuất theo kích thước 500x500mm hay 1000x1000mm.

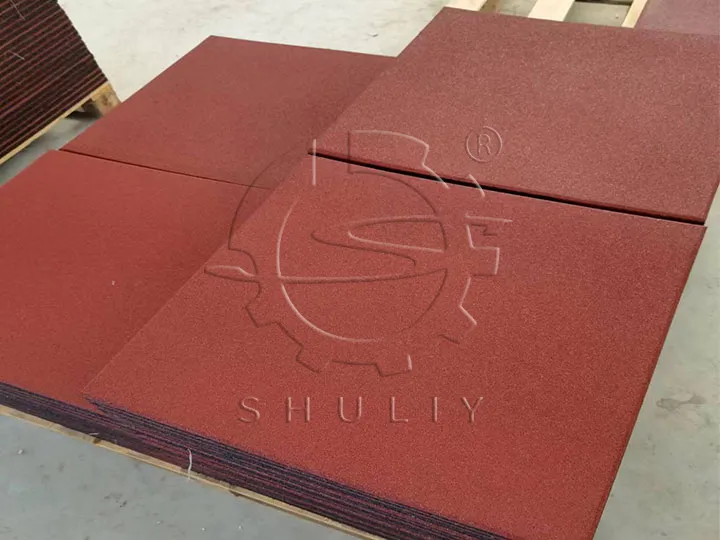

Sản phẩm cuối cùng của máy làm gạch cao su

Công nghệ khuôn phủ Teflon bao gồm

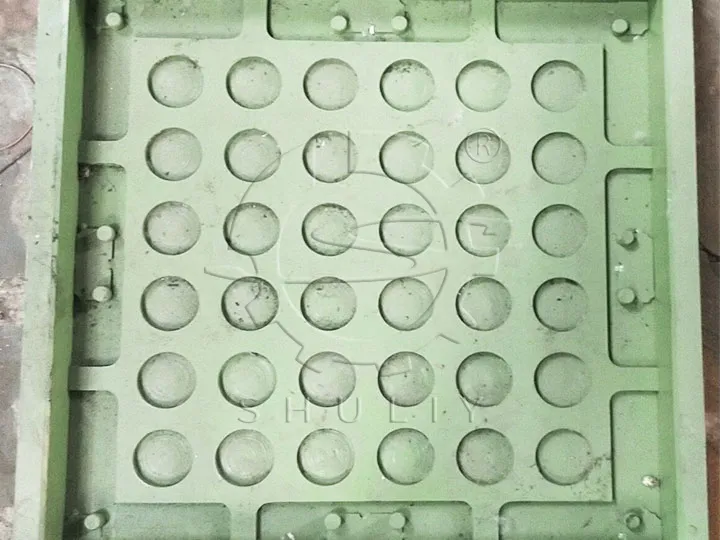

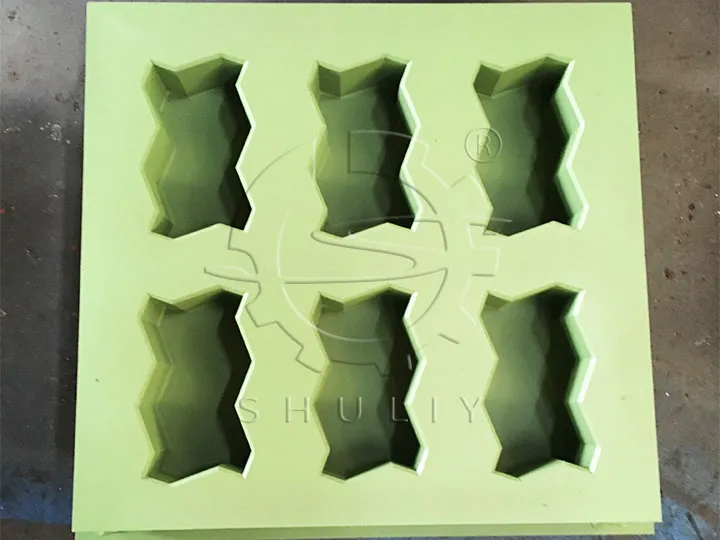

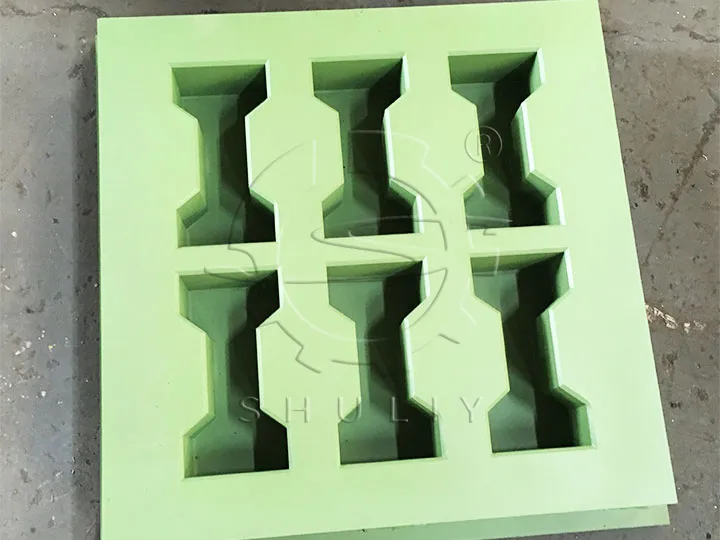

Một điểm nghẽn chính trong sản xuất gạch cao su là lao động thủ công cần thiết để tháo khuôn. Các khuôn đặc biệt của chúng tôi sử dụng quy trình phủ Teflon, mang lại lợi thế cạnh tranh rõ ràng:

- Chế độ chống dính: Lớp phủ Teflon loại bỏ nhu cầu sử dụng chất tẩy rửa trước mỗi chu trình. Điều này giảm chi phí tiêu hao và ngăn ngừa tích tụ hóa chất trên bề mặt viên gạch.

- Độ dày điều chỉnh được: Mỗi bộ khuôn được trang bị dụng cụ điều chỉnh, cho phép sản xuất bốn độ dày cụ thể: 15, 20, 25 và 30mm.

- Tiện lợi tiếp cận: Thiết kế ray trượt giảm thiểu sức ép vật lý lên người vận hành, cho phép di chuyển các khuôn nặng vào và ra khỏi các lớp làm nóng với lực cản tối thiểu.

Tối ưu hóa quy trình làm việc cho máy làm gạch sàn cao su

Hiệu quả trong nhà máy sản xuất được đo bằng thời gian chu kỳ và độ tinh khiết. SL-120T Pro hoạt động theo chu trình đồng bộ gồm làm nóng, định hình và lưu hóa. Để đạt kết quả tốt nhất, quá trình sản xuất tuân theo quy trình kỹ thuật nghiêm ngặt:

- Chuẩn bị vật liệu: Sử dụng máy trộn bột cao su 250# (4kw, 18 vòng/phút), hạt nhỏ được trộn với màu sắc và keo dán trong 4-6 phút.

- Lát hai lớp: Các hạt màu sắc mịn 0.6-1mm được lát cho bề mặt trên, tiếp theo là các hạt thô 1-4mm (thường được tái chế trực tiếp từ một dây chuyền tái chế lốp) cho lớp nền để tối ưu hóa chi phí vật liệu.

- Lưu hóa chính xác: Khuôn được đặt vào trong máy ép, nơi hệ thống PLC quản lý chu trình lưu hóa 3-8 phút ở áp lực làm việc 20Mpa.

Thông số kỹ thuật: Dòng SL-120T Pro

| Thông số kỹ thuật | Giá trị thông số kỹ thuật |

|---|---|

| Tên mô hình | Máy ép lưu hóa SL-120T Pro |

| Lực kẹp danh nghĩa | 1.2 MN (120 Tấn) |

| Kích thước đĩa nóng | 1100 x 1100 x 60 mm |

| Áp lực làm việc tối đa | 20 Mpa |

| Số lớp làm việc | 2 lớp |

| **Hành trình xi lanh piston** | 300 mm |

| Số lượng xi lanh | 4 đơn vị (Φ160mm) |

| Hệ thống điều khiển | Điều khiển tự động PLC |

| Trọng lượng tổng cộng | 6 Tấn |

Thêm hình ảnh của máy ép lưu hóa gạch cao su

Sản phẩm hot

Máy nghiền nhựa thải cho tái chế PP LDPE HDPE

Máy nghiền nhựa phế liệu cắt các vật liệu nhựa thành…

Máy sản xuất gạch cao su công nghiệp cho sản xuất mật độ cao

SL-120T Pro là một máy làm sàn cao su chuyên nghiệp…

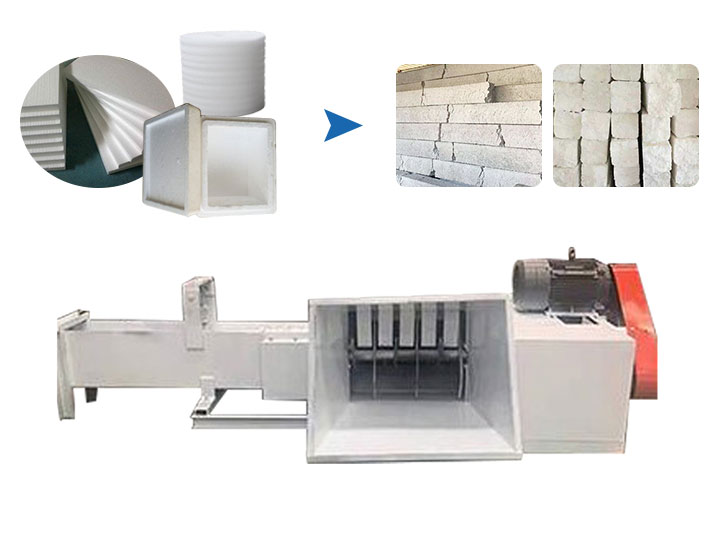

Máy nén EPS/Styrofoam nóng chảy

Mô tả về máy nén xốp Styrofoam Máy nén xốp Styrofoam…

Máy quay cho Tái chế chai PET

Máy sàng này dùng để tái chế chai PET chủ yếu…

Máy nghiền hủy túi nhựa

Máy nghiền túi nhựa là một loại…

Máy nghiền EPS | Máy tái chế bọt polystyrene mở rộng

Máy nghiền EPS chủ yếu phù hợp cho việc làm nhanh bọt…

Máy tạo viên sợi cho tái chế nhựa cứng

Máy tạo viên sợi cung cấp công nghệ tạo viên tái chế cho…

Máy nén bọt EPS nằm ngang

Chức năng của máy nén bọt EPS nằm ngang…

Máy cắt khối cao su chính xác: Hai mô hình cho dây chuyền tái chế lốp xe

Trong một dây chuyền tái chế bán tự động, quá trình…