Waste plastic extrusion machine temperature control and pellet quality assurance

A stable temperature is essential during the operation of a waste plastic extrusion machine. The instability of temperature can directly affect the usage of the machine and the quality of the final recycled plastic pellets.

In addition, the smoothness of the barrel exhaust port has an equally important impact on the quality of the finished product in the plastic granules extrusion line. This paper will discuss the importance of temperature control and barrel venting in waste plastic extrusion machine, as well as strategies for temperature control at start-up.

The impact of barrel exhaust port on product quality

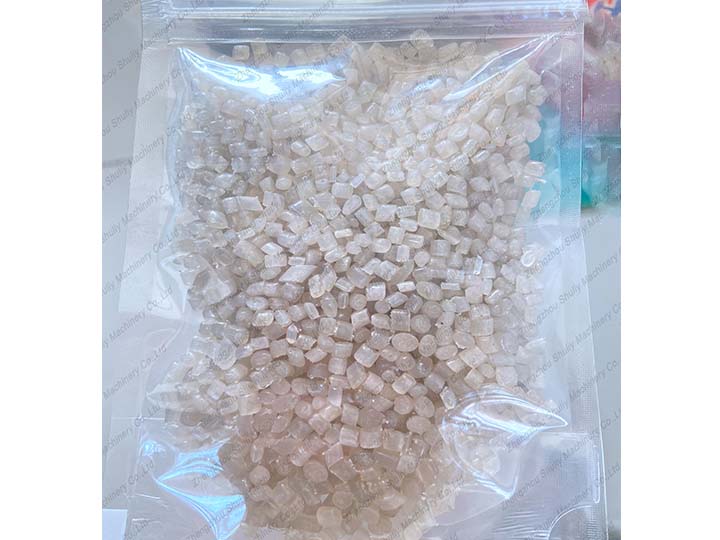

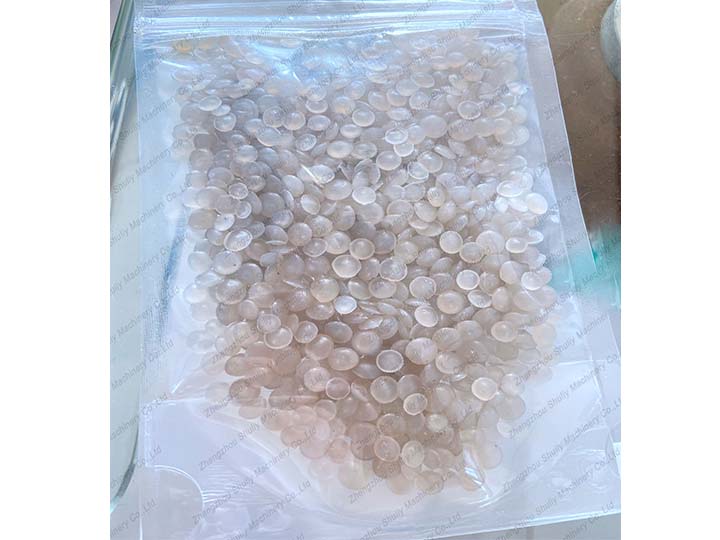

The exhaust port of the barrel of the environmental protection pelletization machine needs to be kept clear during the working process, especially for the discharge of water vapor. By ensuring the smoothness of the barrel exhaust port, it can effectively avoid blistering inside the pellet and thus improve the product quality.

If the barrel exhaust port is clogged or not smooth, water vapor may be trapped inside the pellet, resulting in product quality problems. Therefore, in the operation of environmental protection waste plastic extrusion machine, ensuring the smoothness of the barrel exhaust port is one of the important aspects to ensure recycled plastic pellets quality.

Temperature control strategy at pelletization machine start-up

When starting the waste plastic extrusion machine, do not add material immediately. Make sure the temperature reaches a certain stable state before starting to add material. This is because there will be a small drop in temperature at the beginning of the charge, which will have an impact on the temperature control process of the environmental plastic pelletizer.

To counter this, the temperature needs to be turned up to maintain stability. A common strategy is to set the temperature to 200°C and relatively lower the temperature at the feed inlet, which can be about 20°C below the barrel temperature. This approach is a clever way to avoid damage to the environmental pelletization machine due to temperature problems.

Shuliy Machinery provides high-quality plastic extrusion machine

When purchasing an environmentally friendly pelletization machine, it is vital to choose a machine that meets your needs. shuliy offers you advanced technology and high-quality plastic pelletization machine designed to meet your production needs and provide superior performance and reliability.

We welcome your inquiries at any time and our team of professionals will be happy to recommend the best plastic extrusion machine for you. After the machine is installed, our technicians will guide you to make the best quality plastic pellets. Please don’t hesitate to contact us and let’s contribute to the success of your business together!