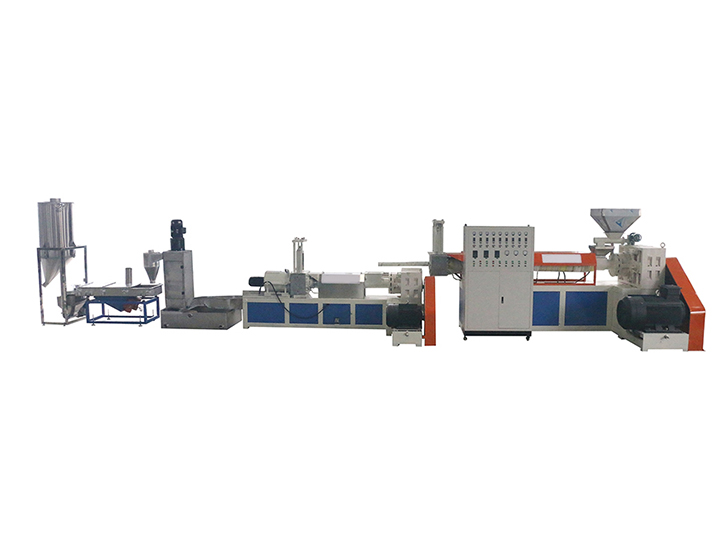

High-efficiency waste plastic granulation machinery

The new environmentally-friendly and energy-saving recycled plastic granule unit, environmentally-friendly and energy-saving recycled plastic granule machine is a new plastic granulator that combines high-tech electromagnetic induction heating technology on the basis of professional double-stage plastic recycled granulating machine.

In the field of granular equipment, the heating method often has an epoch-making special meaning in technology. The old-fashioned granulator with coal, firewood and gas as the heating method, and the new automatic equipment or automated combined production line on the other hand also have significant effects on various systems. breakthrough.

In addition to replacing conventional coal, wood, and gas with conventional electric heaters. There are also new inductive heaters based on the high requirements of fast, efficient, safe, high-yield, energy-saving, maintenance-free, intelligent, etc., also called high-frequency heaters, super-audio heaters, energy-saving induction heaters, electromagnetic induction heaters. Smart to do computer heaters. The emergence of this new heating product. Injecting new power into the plastic recycling granulator

Performance characteristics

1. Dual-purpose screw barrel with extended blanking and dehydration and exhaust function, multi-function exhaust mixing screw deceleration with wear-resistant alloy

The machine special heavy-duty square box reducer has the characteristics of high insurance factor, low noise, maintenance, beautiful and durable, and easy to disassemble.

2, the main engine double electric non-stop change network, the auxiliary machine high-strength electric gear type change network, two-stage filter three-mode net backup, taking into account a variety of material processing needs

3. In addition to the high-frequency energy-saving electromagnetic induction heater, the main area can also be equipped with heaters according to the raw materials, and the rest are high-quality stainless steel heaters.

4, luxury vertical, large-capacity central automatic control, with electronic step-down start function, with multiple monitoring and protection functions

Equipment technical parameters and configuration:

Configuration: strong plastic granulator, compression reinforced auxiliary machine, electric heating facility, temperature control heating cabinet, electric screen changing machine head, plastic crusher, washing machine, plastic pelletizer, material feeder, feeding lifting dryer Automatic cutting machine

Note: The configuration can be configured separately according to the actual situation!

Plastic granulator, high-efficiency waste plastic granulation machine