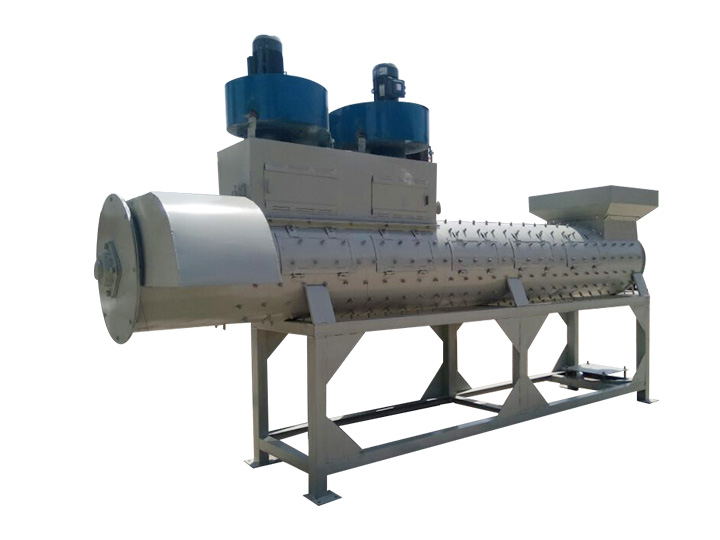

PET bottle label remover recycling machine

PET bottle label remover recycling machine

Features at a Glance

PET bottle label remover is indispensable for plastic bottle recycling and is professional in removing PET bottle labels or water bottle labels, a PET recycling machine can instead of people removing the label during the plastic bottle recycling, meeting the big capacity requirements of the production line. It can improve the efficiency of the PET bottle recycling line.

Main applications of PET bottle label removing machine

Instead of removing plastic bottle labels by labor, the PET bottle de-labeling machine can separate the PVC label and bottle body, greatly improving work efficiency and replacing manual production. It is the prelude to work before the crushing of PET bottle recycling production line. Then finally, the PET recycling machine can reduce the PVC content of PET net flakes for plastic recycling.

Working principle of the PET label removing machine

After the beverage bottle is put into the hopper, the alloy steel cutter in the de-labeling machine will cut a mouth on the trademark on the bottle. When the blade welded on the main shaft has a certain angle with the centerline of the main shaft and the spiral line rotates, the waste bottles will be conveyed to the discharge port, the toothed knife on the blade peels off the label, and then uses wind energy to separate it, which conforms to the modern environmental protection function. After the label paper is peeled off, the bottle body and the label can be automatically separated. Then the label-free plastic bottle will be sent into plastic crushers for further process.

Features of PET bottle label remover

- The PET bottle label remover can save labor with high efficiency, the working rate is about 98%.

- The machine has a large capacity.

- This PET recycling machine has more than 300 pcs special design blades, the material of blades are alloy steel, it is durable.

- By adjusting the blades, it can use for removing different size bottles in plastic bottle recycling.

How to operate PET bottle label remover?

- Start the PET recycling machine first, open the fan motor, then the main machine motor, open the conveyor motor at last.

- Please pay attention to ensure no iron or stone drops into the machine when it working, if it happens, please stop the machine at once.

- When finishing working, please close the conveyor motor first, then the main machine motor, close the fan’s motor last.

Technical Specifications and Performance

Performance and Construction

Our PET bottle label separator is a key machine for the pre-treatment stage of your bottle recycling line. It is designed to help you produce cleaner PET flakes. The machine achieves a high label removal rate of 95-99.5%. This effectively prevents labels from contaminating the recycling stream.

Shuliy bottle label separator use dry-type technology, which removes labels efficiently without using water. The machine body is built with heavy-duty carbon steel for long-term use. A key feature is the barrel wall thickness of 100mm, making it strong enough for continuous, high-intensity operation.

The blades are the core of the our automatic PET bottle delabeler. We use special hard alloy (carbide) blades mounted on a heavy-duty spindle. The blades have a unique serrated and claw-shaped design. This design effectively scrapes and peels labels while pushing the bottles smoothly through the debaler machine.

Configuration and Service

As an experienced recycling machine manufacturer, we offer a range of models with capacities from 500 kg/h up to 5000 kg/h. We aim to provide a cost-effective solution for different plant sizes.

We can customize the PET bottle label separating machine to meet your needs. For example, the machine color can be painted to match your factory’s branding. We will also configure the voltage and frequency to match your country’s standards. A reliable supply of spare parts is available to keep your machine running.

Technical Data Sheet

| Parameter | Model: SL-1500C | Model: SL-2000R |

|---|---|---|

| Application | Compressed Bottles | Round / Uncompressed Bottles |

| Technology Type | Dry Type | Dry Type |

| Capacity | Approx. 1500 kg/h | Approx. 2000 kg/h |

| Efficiency | 90% – 95% | Up to 98% |

| Blade Design | Carbide Serrated Blade | Carbide Serrated Blade |

| Total Motor Power | 37kW + 3kW + 3kW + 0.75kW | 37kW + 3kW + 3kW + 0.75kW |

| Dimension (LWH) | Approx. 6.0m * 1.3m * 1.5m | Approx. 6.0m * 1.3m * 1.5m |

| Standard Accessories | Motor, V-belt, Protective Cover | Motor, V-belt, Protective Cover |

Notes:

- Specifications of Shuliy PET bottle label separatorare based on standard models and may be updated with technical improvements.

- Motor power configuration includes the main drive motor, fan motor, etc.

- We provide guidance for installation and training and offer life-long technical support.

- For details on the warranty or for custom requirements, please contact our technical team for a free consultation.

PET bottle label remover video

Trusted by global recyclers

500kg/h PET Washing Line in Juba, South Sudan

In January 2025, our client, Life Industries in Juba, South Sudan, needed a complete solution to recycle PET bottles and produce high-quality flakes locally.

We provided them with a full 500kg/h PET bottle washing line. Our high-efficiency PET Bottle Label Remover was a key component of this order. This real-world project demonstrates the trust our clients place in our equipment and our ability to deliver end-to-end solutions.

This installation enables our client to turn local plastic waste into a valuable resource, supporting the local economy and environment.

Read the full story on our blog: Shuliy Group Helped Bottle Producer Manufacture PET Bottle Resins in South Sudan

Plastic bottle label removal machine exported to Nigeria

This is one of our customers in Nigeria, he purchased our PET bottle label remover machine one year and found the machine can run very well.

Our Commitment to Quality

Our machines are built to meet international standards. We hold CE and ISO certifications, which guarantee quality, safety, and reliability for our customers worldwide.

Frequently Asked Questions (FAQ)

What is the price of this label remover?

The PET bottle label remover price depends on the model and capacity you need. To get an accurate quote, please tell us your required capacity (e.g., 1000 kg/h) and your local industrial voltage. We will send you a detailed price list.

How often do the blades need to be replaced and is it difficult?

The carbide alloy blades are durable and typically last for 1,500-2,000 working hours. They are designed for easy maintenance. One worker can sharpen or replace a full set of blades in a few hours. A sharpening machine is also available.

Can you ship your PET bottle remover machines to my country in Africa or the Middle East?

Yes, we ship our machines worldwide and have solid experience in these regions. We have successfully delivered equipment to clients in South Sudan and can arrange shipment to major ports like Lagos (Nigeria), Jeddah (Saudi Arabia), and Durban (South Africa).

What kind of after-sales support do you provide?

Shuliy provide a complete support package. This includes detailed instruction manuals, operational videos, and online technical support from our engineers. We offer a 12-month warranty and provide life-long technical support and spare parts.

Inquiry of PET bottle label remover

That’s all the introduction of the PET bottle de-labeling machine, if you are interested in plastic recycling, PET bottle recycling machine and label remover, welcome to consult via Whatsapp/Wechat/Tel: +8619139754732, you can also leave a comment below the page, you will get personalized service and the price.

Hot Product

PET bottle label remover recycling machine

PET bottle label remover is indispensable for plastic…

Vertical & Horizontal Plastic Baler Machine for Bottles Bags Cardboard & More

The commercial plastic baler is mainly used for…

PET bottle flakes hot water washing tank

The hot water washing tank is suitable for…

Plastic film cold washing rinsing tank

The rinsing tank is used for rinsing the…

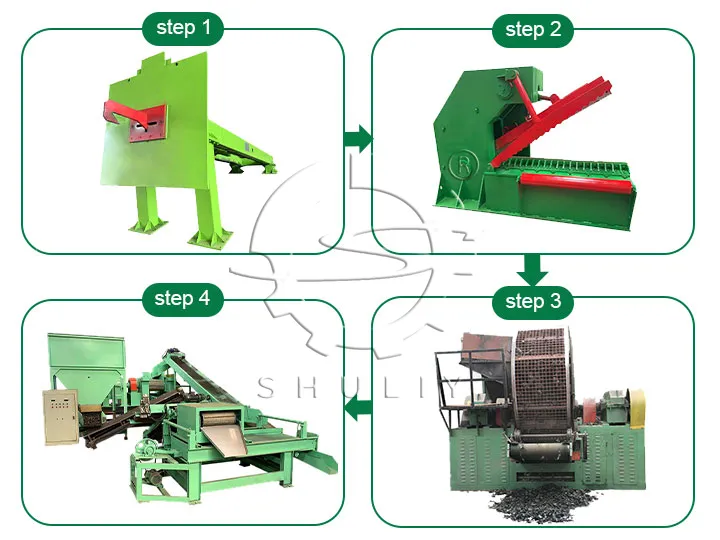

Turnkey OTR Tire Recycling Plant for Mining & Heavy Duty Tires

The disposal of Off-the-Road (OTR) tires presents a…

Waste Gas Filter | Plastic Recycling Filtration System

Pure water-flue gas treatment is a modern standard…

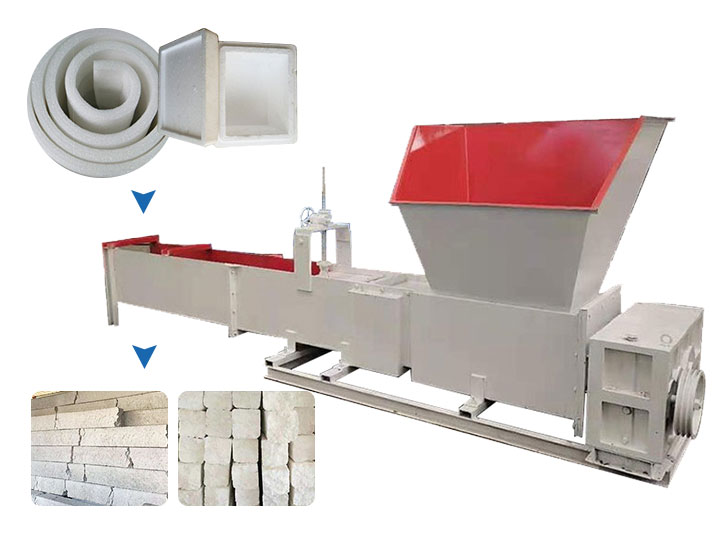

Vertical EPS foam compactor | Styrofoam recycling densifier

Vertical EPS foam compactor is one of the…

PET Plastic Bottle Recycling Machine

Our complete PET bottle recycling line is an…

Automatic rubber powder production line

The automatic rubber powder production line is used…