Vertical & Horizontal Plastic Baler Machine for Bottles Bags Cardboard & More

Vertical & Horizontal Plastic Baler Machine for Bottles Bags Cardboard & More

The commercial baler machine is widely used for compressing and packing various recyclable materials, not just plastics. It is suitable for baling plastic bottles, plastic films, woven bags, foam, cardboard, paper waste, textiles, aluminum cans, and even agricultural waste like straw or hay.

At Shuliy Machinery, we manufacture two main types of balers: vertical balers for small-scale or manual operations, and horizontal balers for higher-capacity, fully automated production lines. Our recycling balers are designed for high-efficiency compacting, making them ideal for use in recycling centers, waste management plants, and industrial packaging facilities.

Classifications of Shuliy plastic balers

1. Vertical plastic baler machine with hydraulic pressure

Technical parameters of plastic film baler

| Model | Pressure(T) | Power(KW) | Dimension(mm) | Capacity(h) | Weight(T) |

| SL-30T | 30 | 5.5 | 800*400*600 | 0.8-1T | 0.8 |

| SL-40T | 30 | 7.5 | 900*600*800 | 1-1.2T | 1.3 |

| SL-60T | 60 | 7.5 | 900*600*800 | 1.5-2T | 1.5 |

| SL-80T | 80 | 11 | 1100*800*1000 | 2-3T | 2 |

| SL-100T | 100 | 15 | 1100*800*1100 | 3-3.5T | 2.8 |

| SL-120T | 120 | 18.5 | 1200*800*1200 | 4-5T | 3.2 |

This vertical plastic packing machine has a variety of specifications, mainly divided according to its hydraulic pressure. The vertical baler has ten levels of hydraulic pressure from 10 tons to 100 tons, which can be selected by users. This type of waste plastic compactor machine is very suitable for small and medium-sized plastic recycling plants. It can efficiently compress large plastic materials into dense blocks (such as 800×400×600 mm to 1200×800×1200 mm), making transportation and subsequent processing more convenient.

Different models of the hydraulic plastic baler have different pressure ratings, output capacities, and bale sizes. For example, the SL-30T can process around 0.8–1 ton per hour, while the SL-100T handles up to 3–3.5 tons per hour. Customers can choose based on their actual production requirements and material characteristics.

Read more about vertical plastic baler cases: Plastic baler shipped to Saudi Arabian plant

Different models of hydraulic plastic balers have different hydraulic pressures and different processing capacities. Customers can choose according to their actual production needs. In addition to packing waste plastic, the packer can also handle other materials, such as waste cardboard boxes, dilapidated clothing, woven bags, cans, scrap metal sheets, straws, etc.

Final products of plastic compactor machine

According to the different models of plastic balers, the weight and density of the compressed material blocks are different, the general density is between 300 and 700 per cubic meter. The final plastic bales will be sent to professional recycling equipment for crushing and pelletizing.

2. Large horizontal plastic packing machine

Technical parameter

| Model | Power(kw) | Preset pressure(Mpa) | cylinder inner diameter | Nominal thrust(KN) | Voltage(v) | Feeding size(mm) | Baling size(mm) | Capacity(t/h) |

| SL-120 | 22+18.5 | 31.5 | D260 | 1200 | 380v | 1800*1020 | 1100*900*1200 | 5-8 |

| SL-160 | 22+18.5 | 31.5 | D280 | 1600 | 380v | 2000*1020 | 1100*1300*1500 | 7-10 |

| SL-200 | 37+22 | 31.5 | D320 | 2000 | 380v | 2200*1200 | 1100*1300*1700 | 10-15 |

The horizontal plastic balers are generally large in size, making them ideal for the large-scale processing of plastic waste. The structure of this commercial waste plastic packer is more complex, but its operation is very intelligent and simple. Horizontal plastic baler is a mechanical and electrical integration and has a very high degree of automation. It is mainly composed of a mechanical system, a control system, a feeding system, and a power system.

Read more about Shuliy baler cases: Plastic bottle baler exported to Nigeria

When the plastic baler works, it is usually used with large automatic conveying equipment, which can save labor and has a very high work efficiency. In addition, the scope of application of the baler machine is also very wide, not only can pack various plastic bottles, plastic shells, plastic bags, but also waste paper, cans, domestic garbage, metal waste, straw, etc.

Main features of the hydraulic plastic baler machine

1. The plastic baler uses hydraulic transmission. The design of the machine is very reasonable, the structure is compact, and the hydraulic performance is reliable. Plastic balers have high working efficiency, low energy consumption, easy installation and operation, safe and reliable use, and strong adaptability to the working environment.

2. Automatic plastic baler has the characteristics of small size, small motion inertia, low noise, smooth movement, flexible operation, and so on. It adopts integrated hydraulic and electric control, which is simple and convenient to use and can be stopped and operated at any working position, and it is easy to achieve overload protection.

More materials you can bale by our baler

Cardboard Baling Solutions for Recycling Centers and Warehouses

In addition to plastic waste, many recycling facilities also deal with large volumes of cardboard and packaging paper. For customers looking for a baling machine for cardboard, the above vertical and horizontal models that can easily compress corrugated boxes, kraft paper, and carton scraps into dense, manageable bales.

Our cardboard baler for sale is designed with high compression force and user-friendly operation, making it ideal for logistics warehouses, retail distribution centers, and waste collection points. Whether you need a compact baler for small-scale use or a high-capacity cardboard compactor for sale for industrial applications, we can provide a reliable solution tailored to your needs.

Textile Baling Solutions for Used Clothes and Fabric Waste

If your recycling operation also involves compressing fabrics, garments, or production offcuts, our textile baler machine is an excellent choice. It is specially designed to handle used clothing, cotton waste, denim scraps, wool, and other textile materials, compressing them into dense and easy-to-transport bales.

Our vertical textile baler machines are widely used by second-hand clothing exporters, donation centers, and textile factories to reduce storage space and optimize logistics. Whether you’re dealing with post-consumer garments or textile factory leftovers, we offer the right textile baler for sale to support your business needs. The final bales are neat, stackable, and ready for export or further processing.

Hot Product

PET bottle label remover recycling machine

PET bottle label remover is indispensable for plastic…

Plastic Film Granulator for PP PE LDPE LLDPE Recycle

The plastic film granulator by Shuliy is a…

PET Plastic Bottle Recycling Machine

Our complete PET bottle recycling line is an…

Waste tire recycling line | rubber granules making machine

The waste tire recycling line uses advanced tire…

Rigid Plastic Shredder Machine

Shuliy rigid plastic shredder machine is also called…

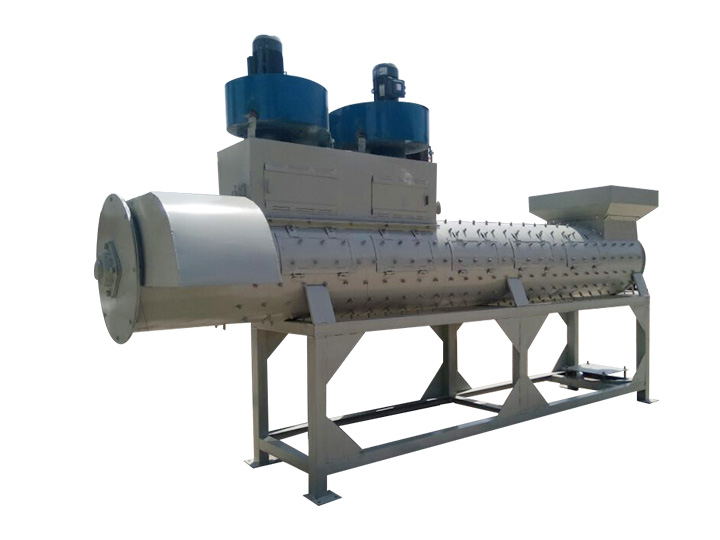

Horizontal Styrofoam Shredder

A horizontal styrofoam shredder is mainly used to…

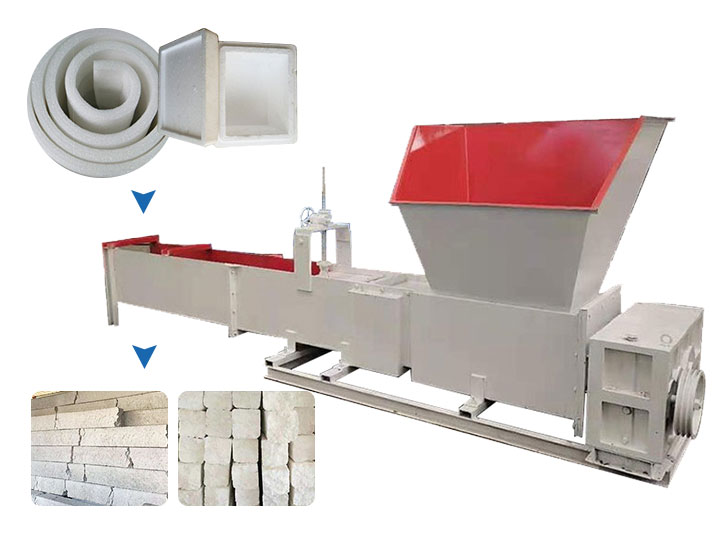

Vertical EPS foam compactor | Styrofoam recycling densifier

Vertical EPS foam compactor is one of the…

Plastic pellet bagging machine | Packing machine

Waste plastic needs to be packaged completely after being processed…

Automatic feeding machine | Forced feeder for plastic recycling

This automatic feeding machine is designed to simulate…